I have a wet UFH to wire up.

Its all been plumbed in, and the plumbers have long gone, so I can't ask them these questions, so I hope some one here could advise.

The existing heating system is an s plan

A single zone wet underfloor heating zone needs to be added, so an S plan Plus.

The heating and hot water are controlled via a nest stat.

The UFH could be switched on with the heating, but Im thinking its better to have it on its own stat, so can come on earlier, and be set to the room.

The pipe work up to the UFH manifold is hot, as its fed from the heating (radiator) circuit. and is stopped from flowing into the UFH circuit by the two port valve on the manifold.

This is where I start to get a bit unsure.

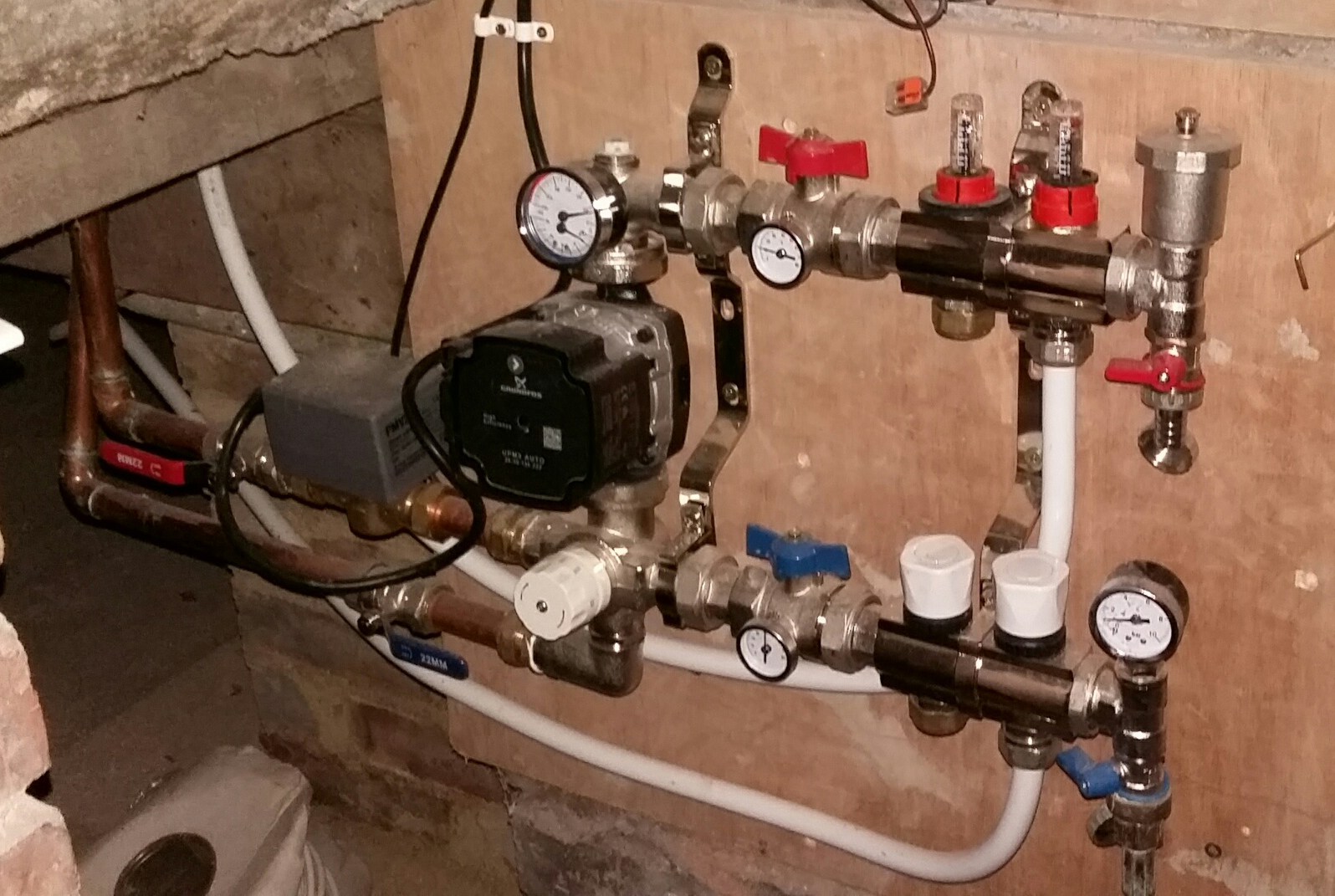

The manifold has no instructions, and no makers mark for me to look it up.

Its only a single zone, but, it looks like they could be two, and it has it has no actuator heads.

So I am wondering if the flow to the UFH is controlled by the manifold two port valve, as there is no wiring centre with the manifold, and no actuator heads to power on or off.

So when the two port valve opens, via the new UFH stat, it switches on the manifold pump, (and the boiler pump and the boiler, if not already calling) and hot water flows to the UFH.

Does that make any sense at all

many thanks

Its all been plumbed in, and the plumbers have long gone, so I can't ask them these questions, so I hope some one here could advise.

The existing heating system is an s plan

A single zone wet underfloor heating zone needs to be added, so an S plan Plus.

The heating and hot water are controlled via a nest stat.

The UFH could be switched on with the heating, but Im thinking its better to have it on its own stat, so can come on earlier, and be set to the room.

The pipe work up to the UFH manifold is hot, as its fed from the heating (radiator) circuit. and is stopped from flowing into the UFH circuit by the two port valve on the manifold.

This is where I start to get a bit unsure.

The manifold has no instructions, and no makers mark for me to look it up.

Its only a single zone, but, it looks like they could be two, and it has it has no actuator heads.

So I am wondering if the flow to the UFH is controlled by the manifold two port valve, as there is no wiring centre with the manifold, and no actuator heads to power on or off.

So when the two port valve opens, via the new UFH stat, it switches on the manifold pump, (and the boiler pump and the boiler, if not already calling) and hot water flows to the UFH.

Does that make any sense at all

many thanks