Hi

Yesterday I fitted a new DHW heat exchanger to this system (vcw 242) as my old plastic one was leaking. Now its a proper Vaillant part and I even changed the divertor valve disc even though there is not much scale up this area.

Whilst I had the valve dismantled I done a mini refurb on it,cleaned it up and greased the diaphragm spindle as it was a little sticky.

Problem now is that the hot water is not hot enough,flow rate is 10L/min but it is only lukewarm.

Tried adjusting hot water temp. valve on boiler but does not make much difference.

Diverter valve appears to be working as ch flow pipe gets hot when dhw is turned off.

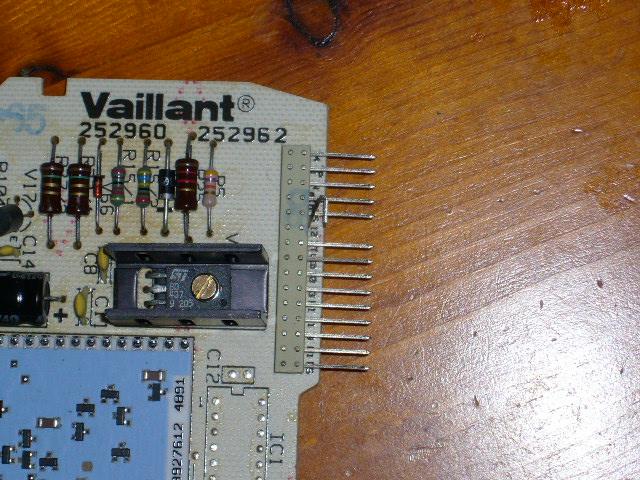

I have also cut link w18 on cct board as my boiler is a hybrid (does anyone know why you need to cut this wire when you change heat exchangers ?)

I have a slight water leak from the hot water temp valve on the boiler but it looks like this has been there a while.

Should the replacement heat exchanger offer a similar performance to the old one as the new one is a much smaller sardine can type?

Any help greatly appreciated as I am out of ideas now...

Yesterday I fitted a new DHW heat exchanger to this system (vcw 242) as my old plastic one was leaking. Now its a proper Vaillant part and I even changed the divertor valve disc even though there is not much scale up this area.

Whilst I had the valve dismantled I done a mini refurb on it,cleaned it up and greased the diaphragm spindle as it was a little sticky.

Problem now is that the hot water is not hot enough,flow rate is 10L/min but it is only lukewarm.

Tried adjusting hot water temp. valve on boiler but does not make much difference.

Diverter valve appears to be working as ch flow pipe gets hot when dhw is turned off.

I have also cut link w18 on cct board as my boiler is a hybrid (does anyone know why you need to cut this wire when you change heat exchangers ?)

I have a slight water leak from the hot water temp valve on the boiler but it looks like this has been there a while.

Should the replacement heat exchanger offer a similar performance to the old one as the new one is a much smaller sardine can type?

Any help greatly appreciated as I am out of ideas now...