Before I install roof insulation boards and seal and line the walls of a timber garden building, I need to be sure I'm doing the right thing before I start. This is my first significant DIY build project so informed guidance is appreciated.

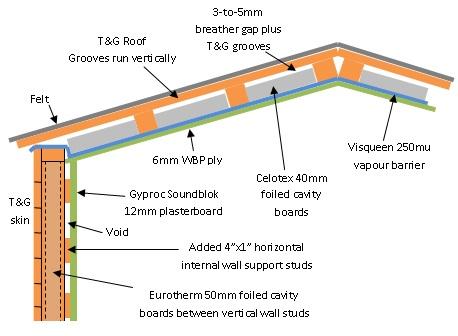

Following advice from a previous post I've installed foil-covered 50mm Eurotherm boards between the 60mm wall support timbers (external wall 22mm T&G), leaving a few mm between the T&G wall and boards, and also the vertical timbers standing a few mm proud internally. I've uploaded an image of the building internals as it is at the moment.

Ahead of my questions, I propose to do the following...

Walls...

1. Vapour-seal all gaps with 200mm foil tape over the timbers to the cavity boards.

2. Attach 4" x 1"s horizontally at right-angles to the wall timbers, running the full length of the walls. These will also provide convenient behind-wall cabling channels at both floor and bench heights once fitted.

3. Tack a visqueen vapour barrier covering the horizontal timbers and then Gyproc soundblok plasterboards on top.

Question:

Should (can) I completely seal off the cavity between the plasterboard and the cavity boards, or should I ventilate it internally to avoid a vapour trap?

T&G Roof...

1. Fill the cavities with 40mm foil-faced cavity boards (T&G board profiles affording vertical-running ventilation grooves above, and aeration at the apex where support beams run through the end walls with small clearance gaps).

2. Tack a visqueen vapour barrier over the support beams and cavity boards, running out over the top of the walls to allow natural air-flow between the soffits and T&G grooves to the apex.

3. WBP ply sheet on top of the visqueen for the ceiling.

Questions:

Is this roof ventilation scheme likely to be sufficient, or will it be better to completely seal off the roof from the soffits? The top of the cavity boards will be 3-5mm below the T&G roof timbers.

Conversely, will ventilation actually need to be increased by laying insulation boards on top of the existing roof timbers (not prefered due to reduced headroom)?

Thank you in advance.

FJ