For those wondering these

are plug/sockets common in France but not in the UK, as to which is the plug and which is the socket I can't say, I would call the wall mounted unit a socket, but if you get down to earth then it is a plug!

As to accident yes nasty, it does pose the question are switches on sockets good or bad? With no switch it would not have happened. The sound and some times flash of removing a plug when under load is stopped when a switch is fitted, and also the chance of touching a live pin, however with modern plugs with plastic insulators on the pins it is no longer really required.

I think it highlights the difference between switching off and isolating. Not so much with sockets, but with lights so many switches today don't isolate, there must be some current flowing to work the electronics, other wise the remote control would not switch it on.

It is so easy to fit sockets with the line and neutral reversed, I remember having boxes of sockets and one box the line and neutral were reversed, so easy on a second fix not to read the writing on every socket, if you have fitted 20 sockets in a row with line on left if the 21st socket has line on right it is so easy to miss. The same applies when renewing a socket, one does not naturally expect the line and neutral to reverse between old and new.

I have been reasonably lucky, after a nasty shock due to shared neutral, I have used a neon screwdriver a lot for terminals, OK today I have a clamp on ammeter, but not always enough room to clip it on, so I am a great believer in the neon screwdriver. Not as primary testing device, but as second string to ones bow.

I got a belt in my father-in-laws house, I am so use to houses with RCD's fitted, his lamp has been knocked off a silly hook and was dangling by the cables, I drew the fuse and refitted, put fuse back in, then noticed the metal bell covering wires has dropped a bit, so went to push it back up, there must have been a strand which touched inside of bell cover, the strand was soon melted and auto removed, but not before I got a belt.

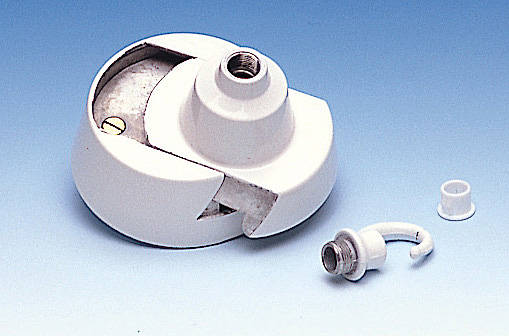

In my late mothers house I also have a large lamp hanging from ceiling which also needs a hook, however I fitted this one, and the whole hook part of ceiling rose slides out, so not balancing on a ladder trying to wire it up. I wire on the floor then simply slide in the plug.

I like the idea however these

are expensive at just over £20 I can see why the cheap versions are used. These

are just over £4 and rated at 5 kg I do wonder however with most ceiling roses rated at 5 kg if during the EICR we were to test ceiling roses could hold 5 kg how many would be pulled out of plaster board? To my mind should be screwed into a beam, however seen many only into plaster board. The metal one with hook still only rated 5 kg by the way.

I think RCD protection has made us sloppy, we do not isolate as we should, many times with a TT house I have only switched off the MCB, I know I should use a double pole isolator not the MCB but I still take a chance. Before the RCD many caravans had a warning light and a push button to reverse to polarity, since the RCD these consumer units seem to have vanished, although I note in my caravan the MCB's are double pole.