- Joined

- 10 Feb 2023

- Messages

- 19

- Reaction score

- 2

- Country

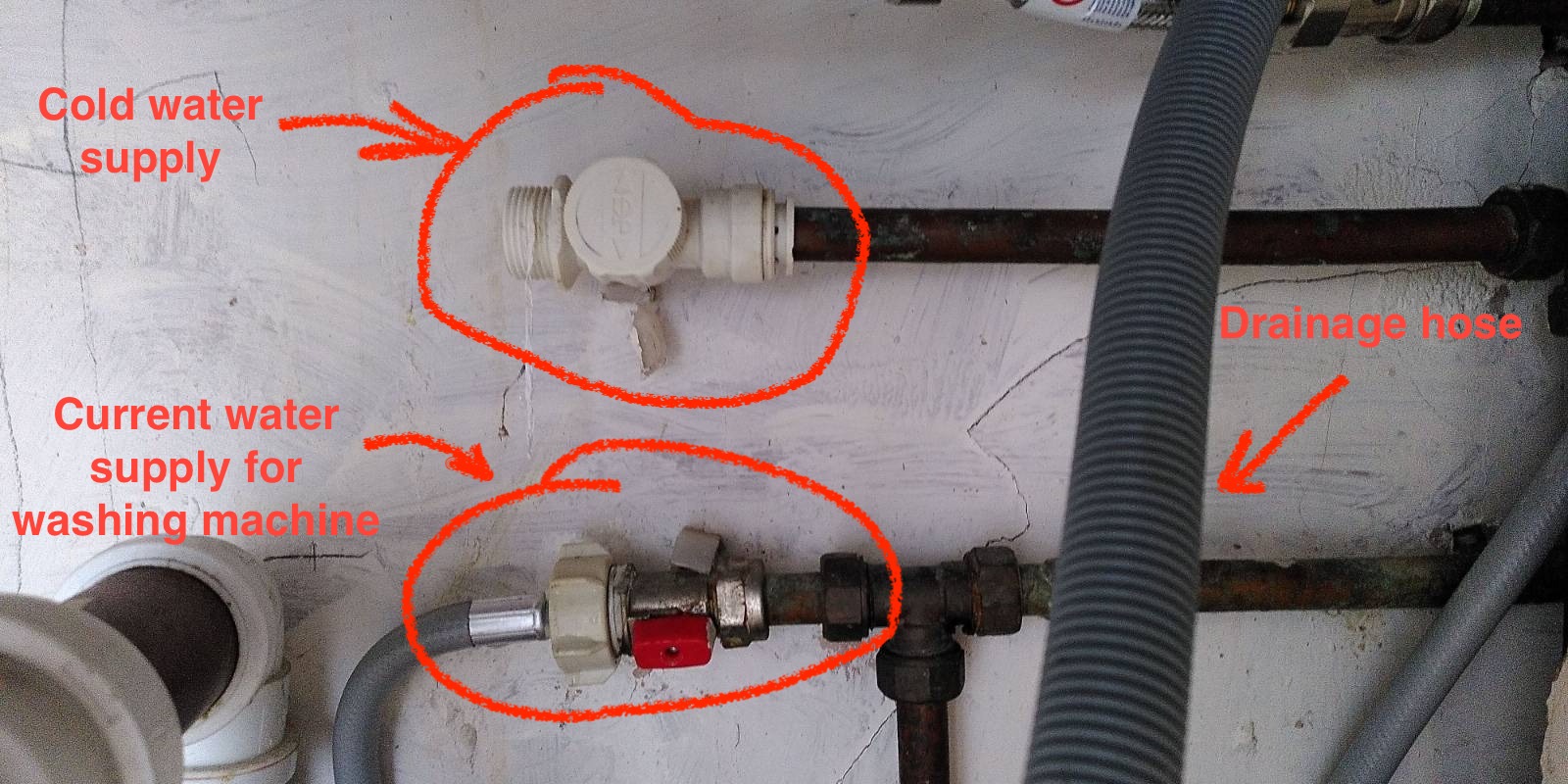

Hi, I've been staying at a friend's house recently and noticed that clothes would always come out of the washing machine hot, no matter what temperature you set it to. I checked under the sink and discovered the hot water supply has been connected to the washing machine.

1 - would it be alright to just use the current (plastic) cold water supply valve and just connect the washing machine to it? Or is it advisable to fit a washing machine compression valve like this one so that there are two distinctly-coloured valves for the future? Are there other benefits of a 'proper' compression valve?

2 - Either way, am I right in thinking that whichever water supply is left disconnected, it should be capped off with something like this to prevent the risk of flooding?

*Additional note - I should say my friend tends to go away for months at a time, hence why I am concerned about avoiding any potential risk of flooding.

1 - would it be alright to just use the current (plastic) cold water supply valve and just connect the washing machine to it? Or is it advisable to fit a washing machine compression valve like this one so that there are two distinctly-coloured valves for the future? Are there other benefits of a 'proper' compression valve?

2 - Either way, am I right in thinking that whichever water supply is left disconnected, it should be capped off with something like this to prevent the risk of flooding?

*Additional note - I should say my friend tends to go away for months at a time, hence why I am concerned about avoiding any potential risk of flooding.