W

wilhelm

well, i just read the first post and he described . w plan.

thats all.

thats all.

Exactamundo!PhilWis said:I reckon there must be wiring fault

CH4 said:PhilWis,

You may be able to do the check with just a mains test screwdriver.

If the wiring is correct, then the problem could be due to the CH and DHW flows being out of balance.

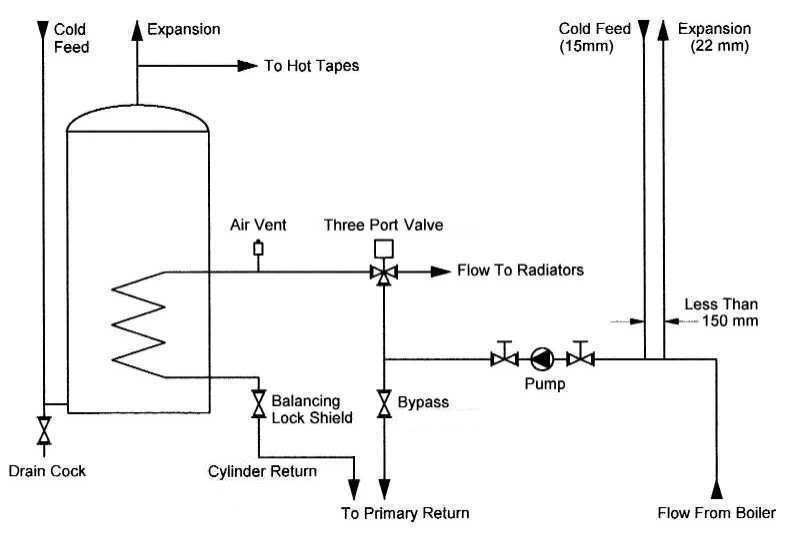

Assuming that your hot water cylinder is at least as old as the previous boiler, its coil is likely to have a low flow resistance, compared to that of a modern high recovery heating coil, and may even have been designed for use in a gravity fed hot water system. If that is the case, the hot water will pass through the coil quickly, give up very little heat and return to the boiler almost as hot as it left. Many new boilers modulate their gas rate in direct proportion to the heating demand. A high return temperature is interpreted as a lack of demand and, consequently, the boiler's output is reduced. If your boiler has a modulating gas valve then, whenever there's a demand for hot water, it may be operating at minimum heat output.

Installing a gate valve (lock shield) inline with the coil would allow the CH and DHW flows to be balanced.

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Are you a trade or supplier? You can create your listing free at DIYnot Local