- Joined

- 16 Dec 2018

- Messages

- 229

- Reaction score

- 2

- Country

Hi, another question about my UFH. I've discussed previously on this forum about my poor UFH insulation -

https://www.diynot.com/diy/threads/spray-foam-underfloor-insulation.602155/#post-5375045

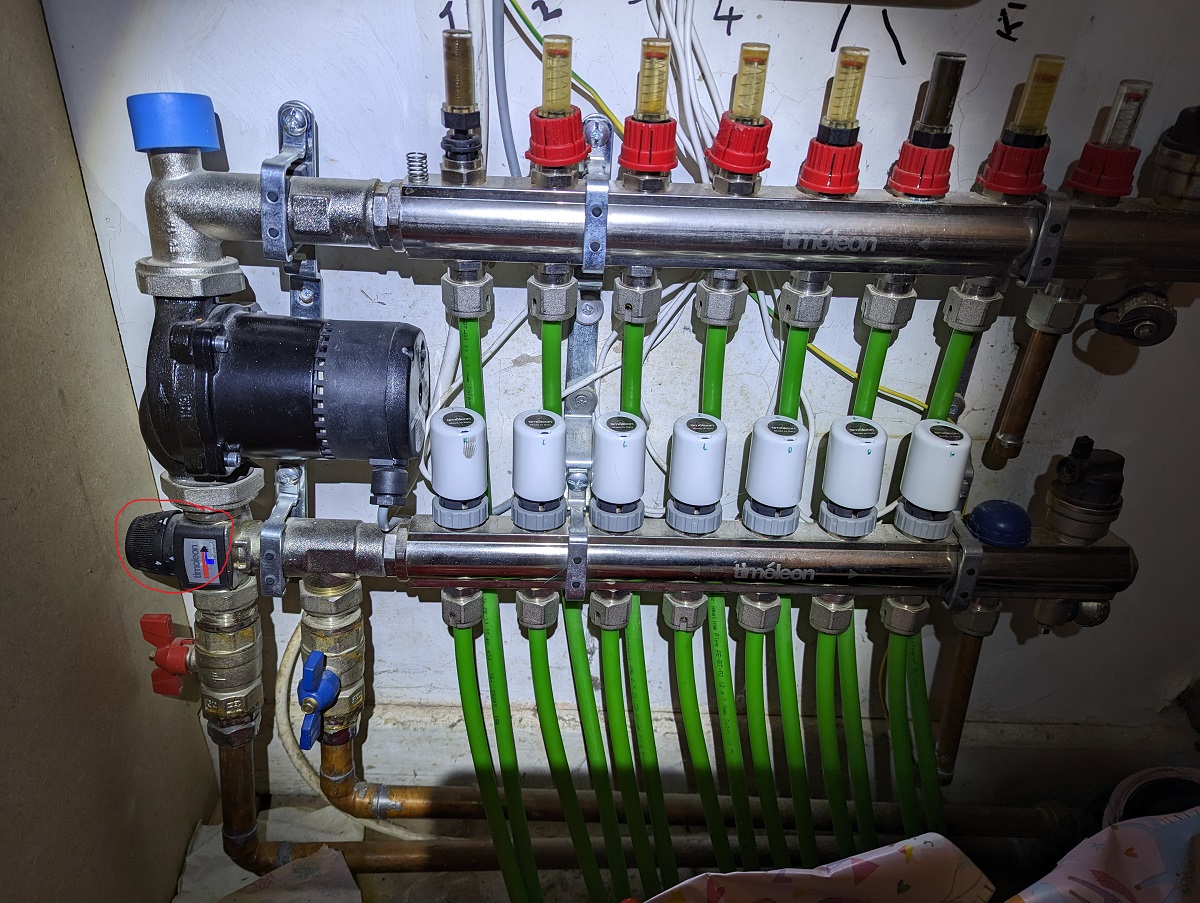

Due to the poor installation/insulation, my UFH doesn't heat the house very well at all. I understand this is down to the above-mentioned insulation, but when my heating was on today, I thought I'd check the temp of the underfloor pipes with my thermal camera, in the hope of maybe turning up the heat. I have a mixed floor covering, tile and engineered oak, both tile and wood floor was around 25c. I then looked at the input temp (I have no temperature gauge), so again, used the thermal camera. The input pipes after the pump read 58c and the return pipes were 48c.

The wife is always asking me why we can't turn up the temperature of the UFH. Is this possible? By the looks of it, the flow input is pretty hot, considering my boiler is set to 67c. I understand the mixer valve cools down the input and I can see mine is set to 4 in the photo below. I did try twisting it but it didn't move? Any ideas?

https://www.diynot.com/diy/threads/spray-foam-underfloor-insulation.602155/#post-5375045

Due to the poor installation/insulation, my UFH doesn't heat the house very well at all. I understand this is down to the above-mentioned insulation, but when my heating was on today, I thought I'd check the temp of the underfloor pipes with my thermal camera, in the hope of maybe turning up the heat. I have a mixed floor covering, tile and engineered oak, both tile and wood floor was around 25c. I then looked at the input temp (I have no temperature gauge), so again, used the thermal camera. The input pipes after the pump read 58c and the return pipes were 48c.

The wife is always asking me why we can't turn up the temperature of the UFH. Is this possible? By the looks of it, the flow input is pretty hot, considering my boiler is set to 67c. I understand the mixer valve cools down the input and I can see mine is set to 4 in the photo below. I did try twisting it but it didn't move? Any ideas?