Not sure what to do with this - any suggestions welcome.

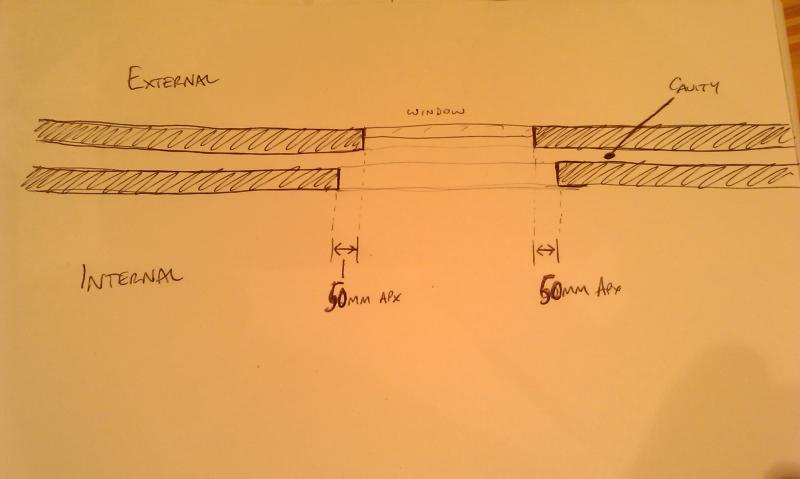

Having taken the plaster off the external cavity wall in this room to enable a complete replaster due to old blown plaster I discovered that above the window there is no internal lintel. There is a large timber one on the external brick skin but nothing on the internal one. The, presumably original, solution had been to nail a bit of plaster mesh up and skim over up to the window reveal. This however had left a whopping great void behind it which I now realise was the reason I had issues with trying to get the curtain rail to stay up! Has anyone got any suggestions as to how I get this flush with the internal brick skin so that I can plaster it up, make the window reveal AND ensure that I have something solid & sound to fix my curtain rail to once the wall is plastered & decorated etc.

I have a attached photos. (Well I thought I had) Try this instead:

//www.diynot.com/network/henkeeper/albums/

Having taken the plaster off the external cavity wall in this room to enable a complete replaster due to old blown plaster I discovered that above the window there is no internal lintel. There is a large timber one on the external brick skin but nothing on the internal one. The, presumably original, solution had been to nail a bit of plaster mesh up and skim over up to the window reveal. This however had left a whopping great void behind it which I now realise was the reason I had issues with trying to get the curtain rail to stay up! Has anyone got any suggestions as to how I get this flush with the internal brick skin so that I can plaster it up, make the window reveal AND ensure that I have something solid & sound to fix my curtain rail to once the wall is plastered & decorated etc.

I have a attached photos. (Well I thought I had) Try this instead:

//www.diynot.com/network/henkeeper/albums/