Hi all,

Sorry if I sound panicky, but I so worried about the quality of this work, I really need some second opinions. They company is due back at my home on Tuesday.

We paid over £12k for 5 new windows and a front door, which included building work of splitting a bedroom window into 2. This building work is what I'm concerned about.

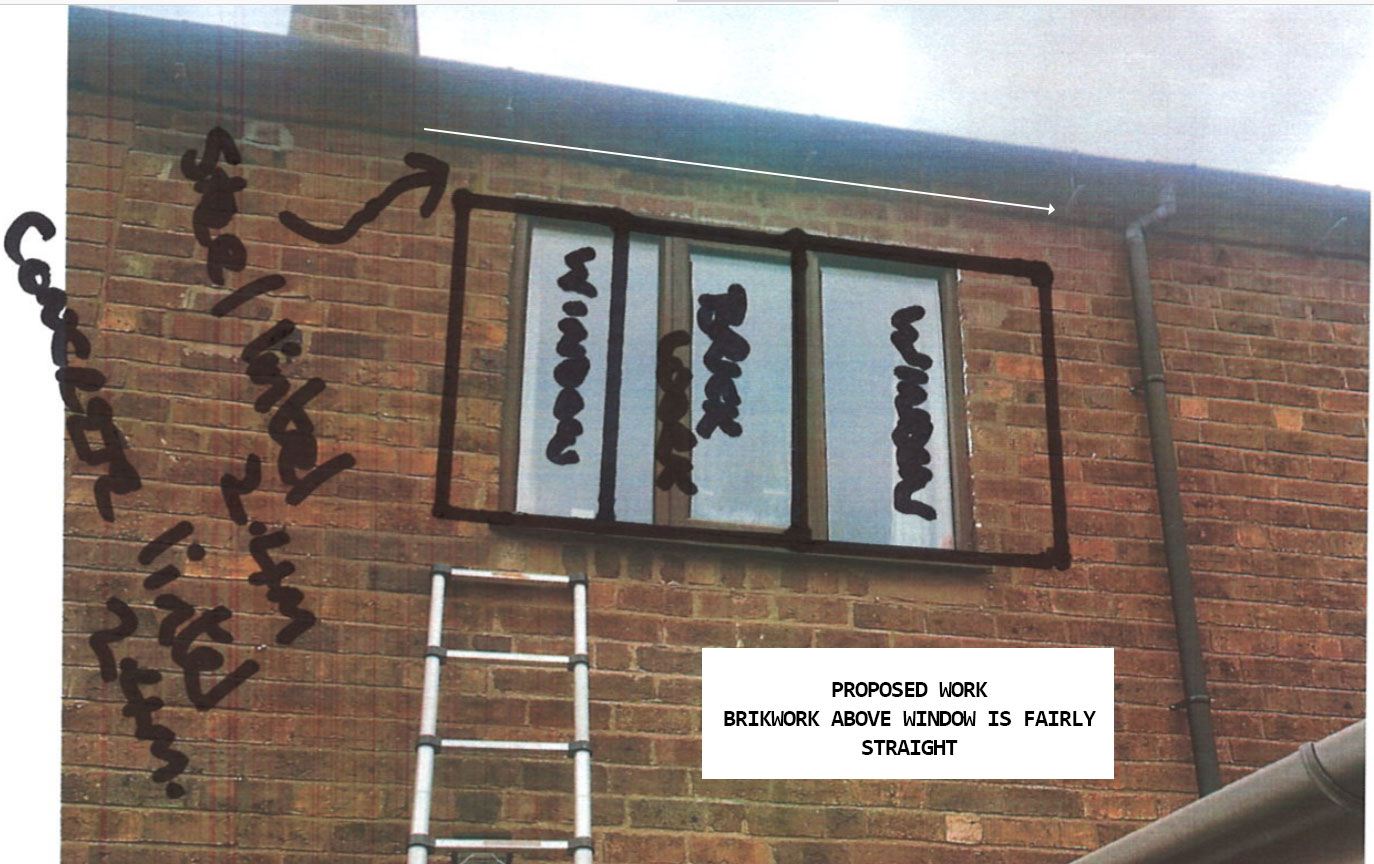

The existing window opening was enlarged and a brick column built in the centre to create 2 separate windows. (photo below)

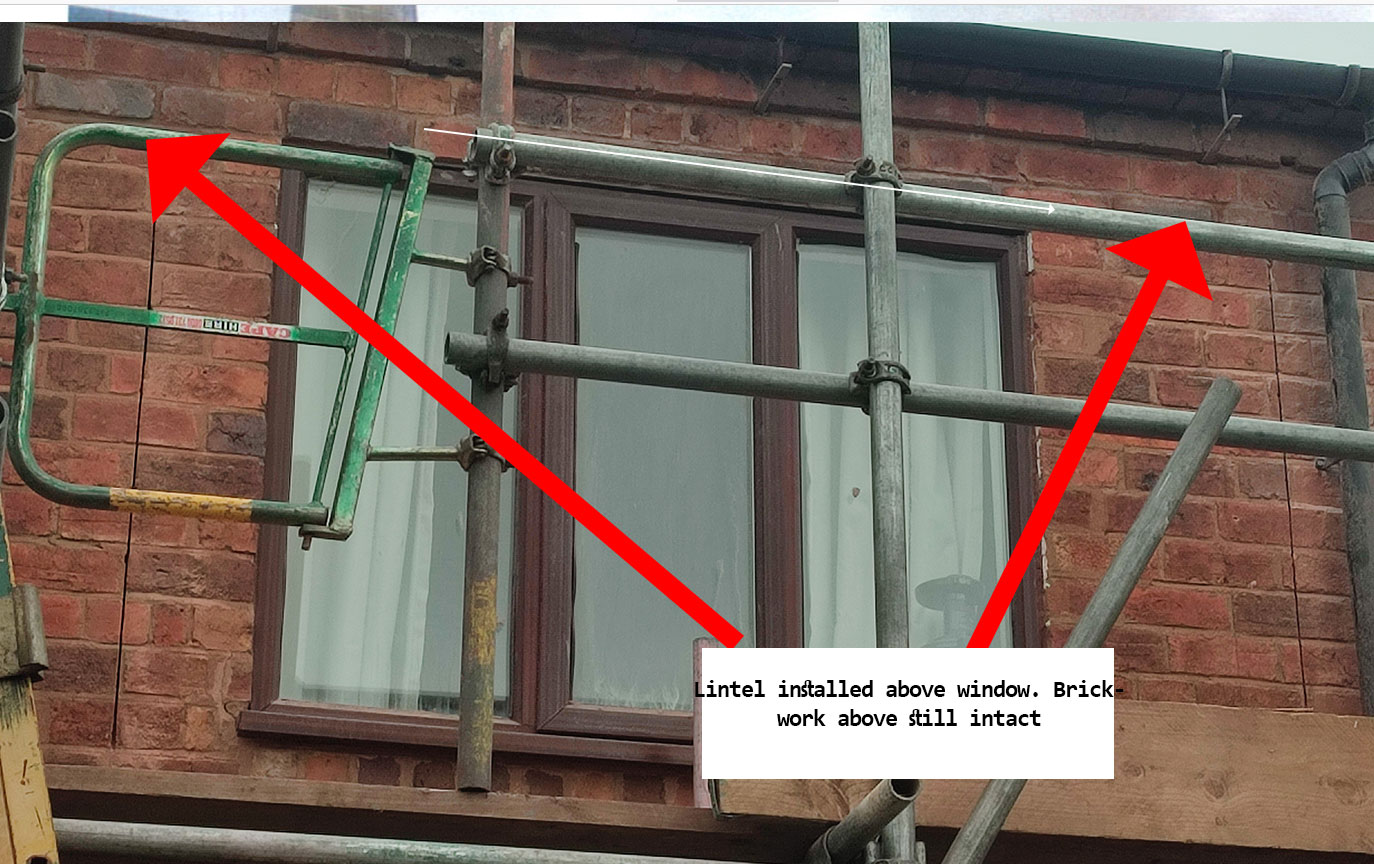

The builder installed the external steel lintel first, then removed the window and enlarged the opening. Then built and centre column of bricks. This photo shows the lintel installed and cut lines in the wall either side of the window.

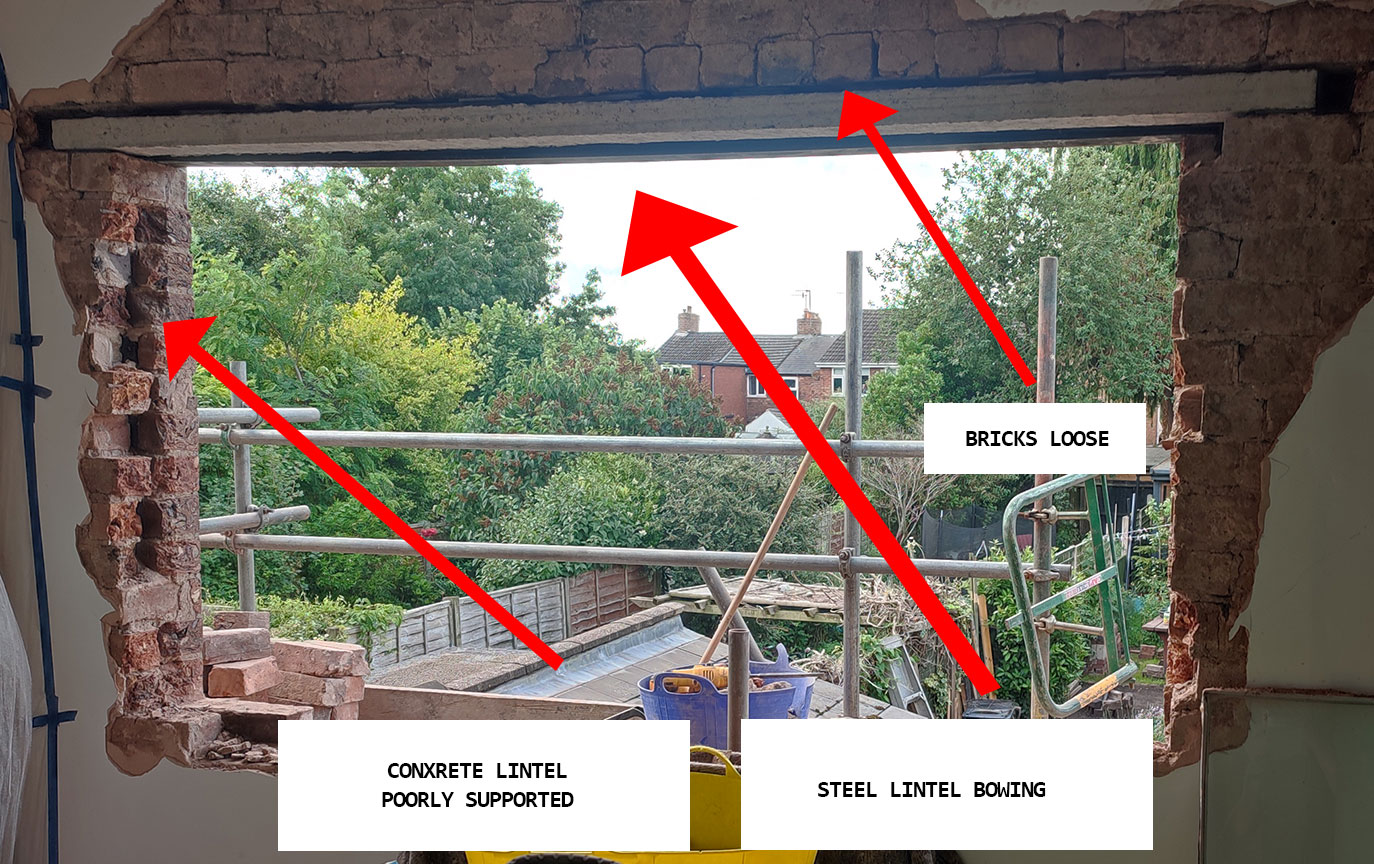

He used an angle grinder to cut the outer skin of bricks. However for the inside skin, instead of grinding or stitch drilling, he just hacked at the wall with a kango meaning the inside edge of the bricks were in a complete mess with lots of bricks missing.

After he made the enlarged opening the external steel lintel was clearly bowing down in the centre, by at least 10mm, probably more like 13mm. You can see this in the next photo

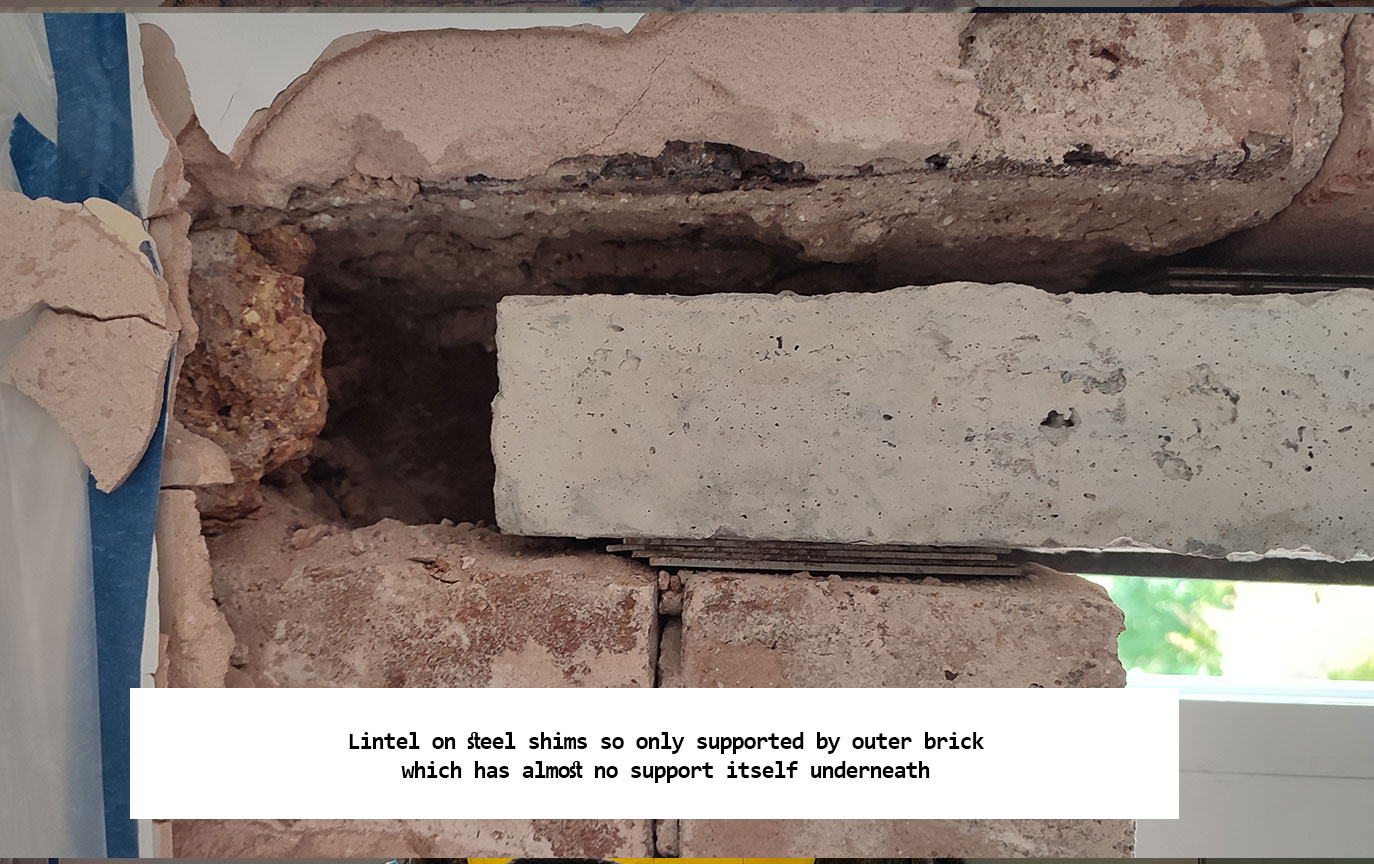

If you look at the left side you can see where he kangoed the bricks (same on the right hand side). The internal concrete lintel is sat on top of this and most of the bricks beneath are missing! Surely this compromises the integrity of the lintel support? Also, the lintel is sat on steel shims (which he has banged in everywhere) so it is effectively only sat on the first brick which is 100mm wide. It doesn't have the required 150mm.

This seems dangerous to me.

Also you can see the external steel lintel bowing down in the center. Surely if this lintel was adequate it should be straight? The lintel is a L shape 2.4m long, 10mm thick and 8cm x 5cm.

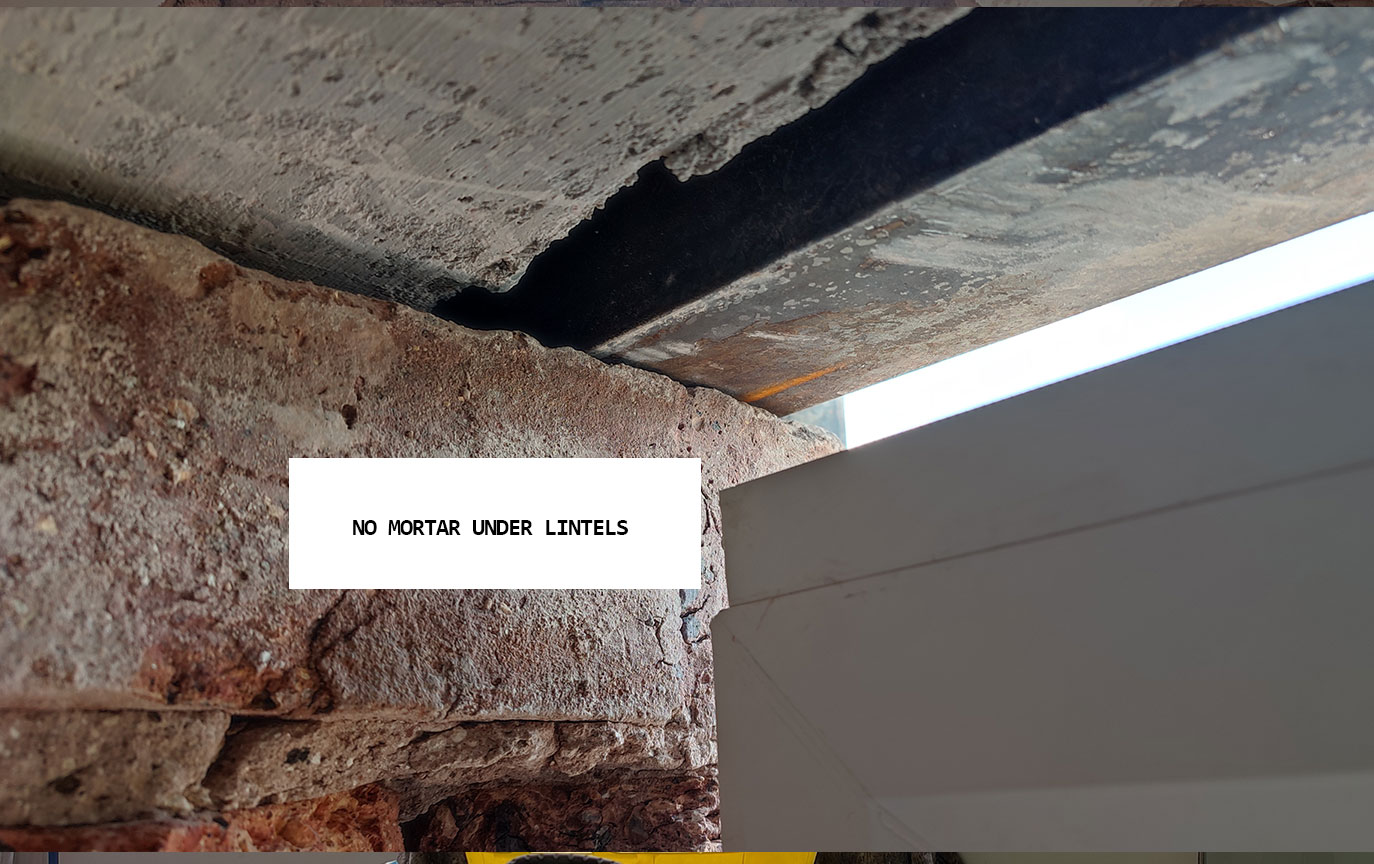

Both lintels are sat on steel shims, not a bed of mortar.

Below you can see the concrete lintel sat on the steel shims meaning it only has 100mm support and missing bricks beneath it.

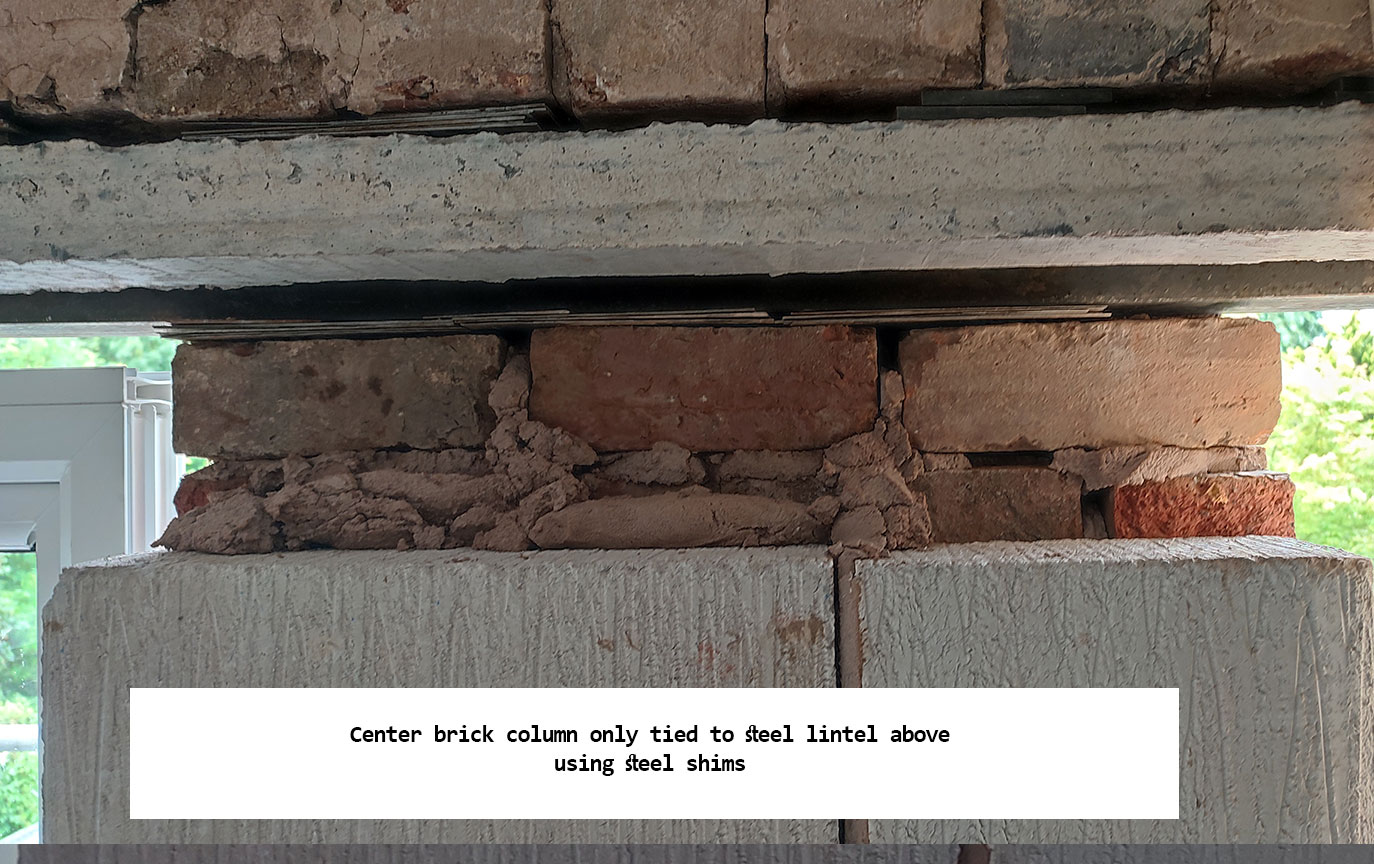

He built the centre column external skin up to the steel lintel, and to 'attach' it to the steel lintel he hammered in steel shims. The internal skin he made from breeze blocks. So the internal and external skins aren't attached together. He put steel shims above the internal breeze block column too. But this column moves if i press it.

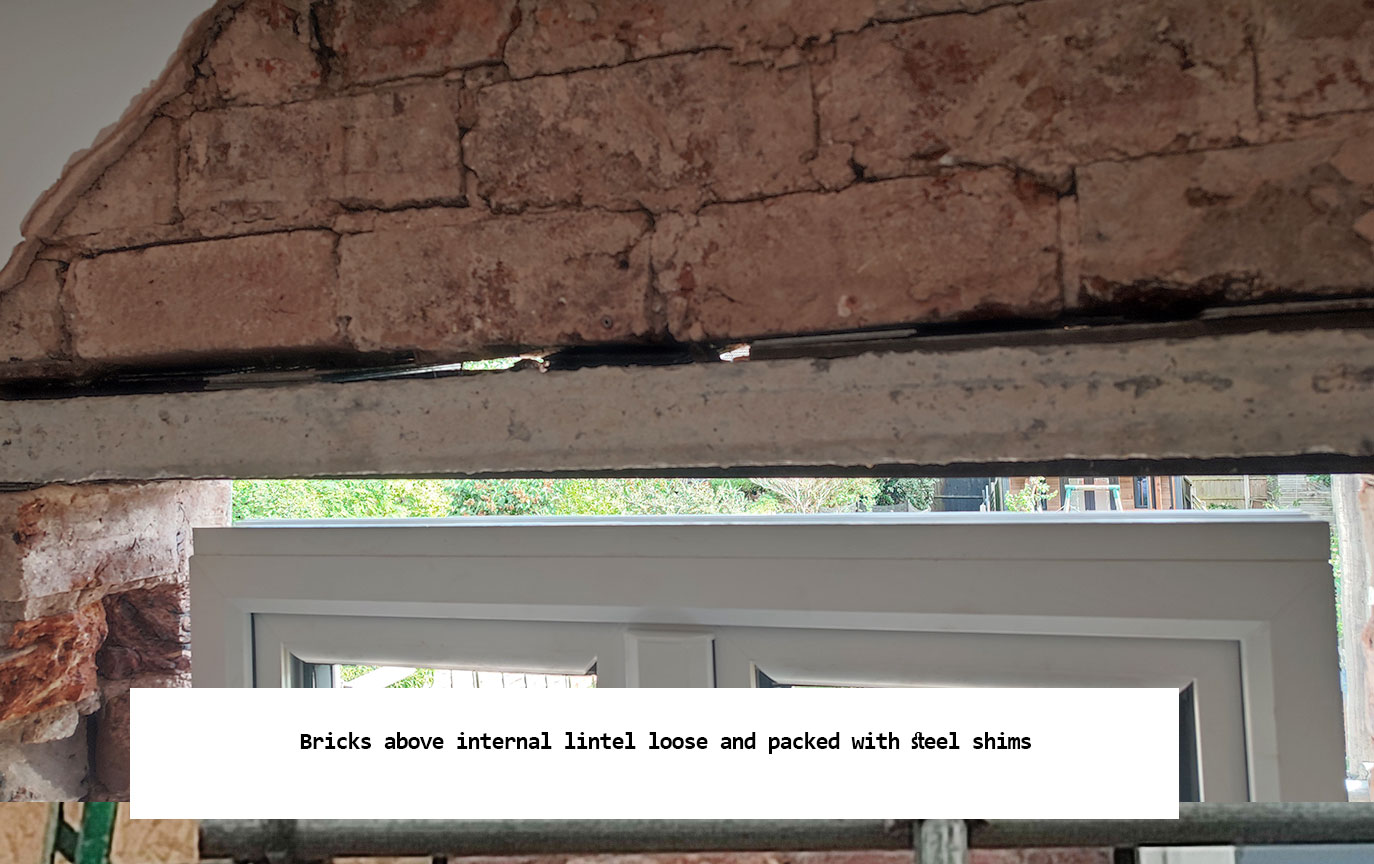

And as you can also see, he has put steel shims everywhere to support bricks which have obviously become dislodged/fallen, maybe because he didn't use acro props, or some other reason.

Is hammering steel shims all over the place normal?

Should I get building control to come and inspect the lintel to see if it meets the standards of support?

Is the centre column of bricks with steel shims above adequately help in place?

Is the steel lintel bending so much normal and not being sat on any mortar etc?

Are steel lintels supposed to have corrosion protection? These have rust patches on them and the ends look like freshly cut steel with no coating at all on them.

I am really worried about this. The stress is killing me. I want to go and talk to them about it tomorrow so some other opinions would really help me.

Many thanks for any help / advice.

Sorry if I sound panicky, but I so worried about the quality of this work, I really need some second opinions. They company is due back at my home on Tuesday.

We paid over £12k for 5 new windows and a front door, which included building work of splitting a bedroom window into 2. This building work is what I'm concerned about.

The existing window opening was enlarged and a brick column built in the centre to create 2 separate windows. (photo below)

The builder installed the external steel lintel first, then removed the window and enlarged the opening. Then built and centre column of bricks. This photo shows the lintel installed and cut lines in the wall either side of the window.

He used an angle grinder to cut the outer skin of bricks. However for the inside skin, instead of grinding or stitch drilling, he just hacked at the wall with a kango meaning the inside edge of the bricks were in a complete mess with lots of bricks missing.

After he made the enlarged opening the external steel lintel was clearly bowing down in the centre, by at least 10mm, probably more like 13mm. You can see this in the next photo

If you look at the left side you can see where he kangoed the bricks (same on the right hand side). The internal concrete lintel is sat on top of this and most of the bricks beneath are missing! Surely this compromises the integrity of the lintel support? Also, the lintel is sat on steel shims (which he has banged in everywhere) so it is effectively only sat on the first brick which is 100mm wide. It doesn't have the required 150mm.

This seems dangerous to me.

Also you can see the external steel lintel bowing down in the center. Surely if this lintel was adequate it should be straight? The lintel is a L shape 2.4m long, 10mm thick and 8cm x 5cm.

Both lintels are sat on steel shims, not a bed of mortar.

Below you can see the concrete lintel sat on the steel shims meaning it only has 100mm support and missing bricks beneath it.

He built the centre column external skin up to the steel lintel, and to 'attach' it to the steel lintel he hammered in steel shims. The internal skin he made from breeze blocks. So the internal and external skins aren't attached together. He put steel shims above the internal breeze block column too. But this column moves if i press it.

And as you can also see, he has put steel shims everywhere to support bricks which have obviously become dislodged/fallen, maybe because he didn't use acro props, or some other reason.

Is hammering steel shims all over the place normal?

Should I get building control to come and inspect the lintel to see if it meets the standards of support?

Is the centre column of bricks with steel shims above adequately help in place?

Is the steel lintel bending so much normal and not being sat on any mortar etc?

Are steel lintels supposed to have corrosion protection? These have rust patches on them and the ends look like freshly cut steel with no coating at all on them.

I am really worried about this. The stress is killing me. I want to go and talk to them about it tomorrow so some other opinions would really help me.

Many thanks for any help / advice.

Last edited: