Aaargh! It's not about maximising sales, it is about having confidence that the assembly will function as intended. You can't expect every manufacturer of CUs to be able to guarantee that his enclosure will allow any make of MCB to function as specified, particulary given the large number of 'cloned' MCBs that are available, or that his MCB will function properly in every make of enclosure that it will fit into. The only way to ensure the correct performance would be to test every possible combination of MCBs and enclosures that would physically fit together. That would push the cost of testing, and hence the price of the product, up to an unrealistic amount. It also wouldn't work in practice, as different manufacturers would not know each others' manufacturing tolerances.attempting to maximise one’s sales by ‘recommending’ that only one’s own MCBs be used in a CU is hardly a very enforceable technique.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Doepke board - can Protek be fitted in them?

- Thread starter sparkybird

- Start date

Sponsored Links

That's obvioulsy the official line, and what the manufacturers would say. In many other situations of 'compatibility', I would have no problem in taking the 'explanation' at face value. However, what I've been suggesting (and, actually, I wasn't the first person in this thread to say so) is that applying that concept to MCBs in a CU is stretching credibilty to a fair extent. Sure, one could think up some 'theoretical possibilities', but do you seriously believe that, in practice, an MCB is going to function significantly differently when housed in a different (but very similar) plastic box?Aaargh! It's not about maximising sales, it is about having confidence that the assembly will function as intended. You can't expect every manufacturer of CUs to be able to guarantee that his enclosure will allow any make of MCB to function as specified, particulary given the large number of 'cloned' MCBs that are available, or that his MCB will function properly in every make of enclosure that it will fit into.attempting to maximise one’s sales by ‘recommending’ that only one’s own MCBs be used in a CU is hardly a very enforceable technique.

If you really do believe that, such 'extremely unlikely possibilities' could be taken to ludicrous extremes. I have, for example, already hypothesised a situation in which a manufacturer of electrical accessories indicated that they had only been tested with one make of cable - and I hope you agree it would be taking things a bit too far to suggest that they should not be used with any other make of cable - even though it would theoretically be 'non-compliant' with BS7671 to use any other cable if the MI specified a particular make.

I'm not blaming the manufacturers. Companies are all in the business of making money, and they would be commercially incompetant if they did not try to promote their own products - every company does. Get a recipe from Tesco, M&S or wherever, and the list of ingredients will often include things such as 'Tesco Plain Flour', as if other makes of flour may not be acceptable. The trouble with electrical items is that, as I've said, the wording of BS7671 is such as to make it theoretically 'non-compliant' to ignore anything included in the 'Manufacturer's Instructions', even if it was written by the marketing department - whereas the average person has the common sense to realise that Waitrose Plain Flour is almost certaibly as acceptable for the recipe as is Tesco's, and that they were 'just trying it on' by sugegsting that one had to use Tesco's flour!

Kind Regards, John.

John, yes, I am indeed confirming that MCBs can function incorrectly if installed in the wrong make of CU. As you well know a CU is somewhat more than just a plastic box, and even if it was just a box it's design could have an effect on long-term performance.That's obvioulsy the official line, and what the manufacturers would say. In many other situations of 'compatibility', I would have no problem in taking the 'explanation' at face value. However, what I've been suggesting (and, actually, I wasn't the first person in this thread to say so) is that applying that concept to MCBs in a CU is stretching credibilty to a fair extent. Sure, one could think up some 'theoretical possibilities', but do you seriously believe that, in practice, an MCB is going to function significantly differently when housed in a different (but very similar) plastic box?Aaargh! It's not about maximising sales, it is about having confidence that the assembly will function as intended. You can't expect every manufacturer of CUs to be able to guarantee that his enclosure will allow any make of MCB to function as specified, particulary given the large number of 'cloned' MCBs that are available, or that his MCB will function properly in every make of enclosure that it will fit into.attempting to maximise one’s sales by ‘recommending’ that only one’s own MCBs be used in a CU is hardly a very enforceable technique.

If you really do believe that, such 'extremely unlikely possibilities' could be taken to ludicrous extremes. I have, for example, already hypothesised a situation in which a manufacturer of electrical accessories indicated that they had only been tested with one make of cable - and I hope you agree it would be taking things a bit too far to suggest that they should not be used with any other make of cable - even though it would theoretically be 'non-compliant' with BS7671 to use any other cable if the MI specified a particular make.

I'm not blaming the manufacturers. Companies are all in the business of making money, and they would be commercially incompetant if they did not try to promote their own products - every company does. Get a recipe from Tesco, M&S or wherever, and the list of ingredients will often include things such as 'Tesco Plain Flour', as if other makes of flour may not be acceptable. The trouble with electrical items is that, as I've said, the wording of BS7671 is such as to make it theoretically 'non-compliant' to ignore anything included in the 'Manufacturer's Instructions', even if it was written by the marketing department - whereas the average person has the common sense to realise that Waitrose Plain Flour is almost certaibly as acceptable for the recipe as is Tesco's, and that they were 'just trying it on' by sugegsting that one had to use Tesco's flour!

Kind Regards, John.

The manufacturer of a CU has to assure himself, his customers, and the relevant authorites that his assembly will comply with the relevant standards whatever combination of his products is installed in that assembly. This is more of a problem as more sophisticated devices are included within CUs; timers, lighting management devices, and other complex electronic devices all have to function in close proximity to the MCB supplying the shower, or the induction hob. Can you realistically expect a manufacturer to condone the use of products from another manufacturer in conjunction with his own? Admittedly MCBs are not terribly sensitive to mounting arrangements, with the exception of those that use a clip-on busbar, and more problems are likely to be caused by cheapo 'clone' MCBs that by the use of the wrong brand of MCB, but that doesn't make it right.

Yes, of course you can imagine this being taken to ludicrous extremes. The manufacturer could tell you to use his brand of screws and wall plugs to fix the CU to the wall, but in the event of a claim against him he'd have to show that use of the wrong brand of screws would affect the performance. I don't believe that would be the case for a claim resulting from the use of a non-type approved assembly within a CU, not because of anything said in BS7671, but because the test requirements in the standard for CUs had not been complied with.

When you fit manufacturer A's MCB in manufacturer B's CU, you are taking responsibility for an untested assembly. I know you'd like MCBs to be generic and interchangeable John, but they aren't until the product standards for MCBs and the assembly standard for CUs are rewritten to change the verification requirements.

The trouble is that what you say is a theoretical possibility, so no-one can say it's actually wrong. However, are you aware of anyone ever having seen an MCB (whose terminal/busbar arrangement was physically compatible) function incorrectly because it was in the 'wrong' make of CU? I seriously doubt if anyone has (indeed, how would one prove that was the reason for malfunction?) and think that, at worst, it is a vanishingly improbable situation.John, yes, I am indeed confirming that MCBs can function incorrectly if installed in the wrong make of CU. As you well know a CU is somewhat more than just a plastic box, and even if it was just a box it's design could have an effect on long-term performance.

You say that a CU is 'more than just a plastic box', but it's very little more. Again provided there was physical terminal/busbar compatability, about the only possible consideration I can think of would be that of heat - so if a CU is physically larger than the 'right' one, I think the probablilty of an MCB malfunctioning beciase it was in the 'wrong' CU would approach zero.

No, as I've said, I don't blame the manufacturers - not only for technical reasons but also, as I said, I would not blame Tesco for specifying their own products in a recipe.Can you realistically expect a manufacturer to condone the use of products from another manufacturer in conjunction with his own?

Agreed, but that wouldn't stop some people, probably including some here, from saying that it was non-compliant with BS7671.Yes, of course you can imagine this being taken to ludicrous extremes. The manufacturer could tell you to use his brand of screws and wall plugs to fix the CU to the wall, but in the event of a claim against him he'd have to show that use of the wrong brand of screws would affect the performance.

That may be correct (I've never read the 'Standard for CUs', whichever that may be), but I don't think it really alters my 'points of principle'. Indeed, it is failure of Standards to impose interchangeability (which is one of the main reasons for the existance of many Standards) which gives rise to the whole situation we are discussing. If Standards require interchangeability of plugs, sockets, lampholders, accessories etc. etc., why not also MCBs?I don't believe that would be the case for a claim resulting from the use of a non-type approved assembly within a CU, not because of anything said in BS7671, but because the test requirements in the standard for CUs had not been complied with.

Kind Regards, John.

Sponsored Links

Well, you're worong. Some busbar configurations are compatible but because of differing tolerances cannot reach full specification when interchanged. I have physical and photographic evidence of more than one expample, but I am not permitted to post them here.The trouble is that what you say is a theoretical possibility, so no-one can say it's actually wrong. However, are you aware of anyone ever having seen an MCB (whose terminal/busbar arrangement was physically compatible) function incorrectly because it was in the 'wrong' make of CU? I seriously doubt if anyone has (indeed, how would one prove that was the reason for malfunction?) and think that, at worst, it is a vanishingly improbable situation.

You're mssing the point with your Tesco recipe analogy. What you're suggesting is that Tesco should guarantee that they're recipe would still work if you used Waitrose flour. It probably would but Tesco can't control Waitrose's quality system, so how could they guarantee it?

BS7671 has little to do with my argument. The standard more relevant to CUs is BS EN 61439-3.

If you want MCBs to be interchangeable, why not go the whole hog and expect that any installation to BS7671 is interchangeable with another? Some standards, usually for simple products such as fasteners, deal with interchageability. Others specify performance objectives. A few do both.

I think you're quibbling a bit there. If the tolerances prevent full interchangeability, I would not call that 'compatible'.Well, you're worong. Some busbar configurations are compatible but because of differing tolerances cannot reach full specification when interchanged.The trouble is that what you say is a theoretical possibility, so no-one can say it's actually wrong. However, are you aware of anyone ever having seen an MCB (whose terminal/busbar arrangement was physically compatible) function incorrectly because it was in the 'wrong' make of CU? I seriously doubt if anyone has (indeed, how would one prove that was the reason for malfunction?) and think that, at worst, it is a vanishingly improbable situation.

Again, what you say is literally true - but my point is the same. I don't think many people would believe that the success of a recipe depended on the make of Plain Flour which was used - and if you believe the (technically valid) reason you mention is the reason why Tesco specify their own products, then I think you may be being slightly naiveYou're mssing the point with your Tesco recipe analogy. What you're suggesting is that Tesco should guarantee that they're recipe would still work if you used Waitrose flour. It probably would but Tesco can't control Waitrose's quality system, so how could they guarantee it?

That is, of course, another 'ludicrous extreme'. Where has common sense and realism gone? Particularly given that I was not the first person to mention this issue in this thread, I'm a little surprised that no-one else has shown themselves with views similar to mine. All of the arguments you are producing are technically correct, but, IMO, are stretching things a bit. Am I the only person who was, to say the least, 'very surprised' when, many years ago, I first discovered that MCBs were not necessarily even physically interchangeable?If you want MCBs to be interchangeable, why not go the whole hog and expect that any installation to BS7671 is interchangeable with another?

Kind Regards, John.

Fork busbars vs comb?Sure, one could think up some 'theoretical possibilities', but do you seriously believe that, in practice, an MCB is going to function significantly differently when housed in a different (but very similar) plastic box?

Different makes having their entry terminals different distances from the rail, leading to fore-aft or vertical misalignments?

Different depths and/or heights of the parts of the MCBs which protrude through the cover, leading to gaps or the inability to fix the cover in place?

None of these are theoretical.

Yes - all of these things could be standardised, but...

a) They aren't.

b) To do so would be an unwarranted regulatory intrusion.

Well, you started with the ludicrous comparisons!That is, of course, another 'ludicrous extreme'. Where has common sense and realism gone? Particularly given that I was not the first person to mention this issue in this thread, I'm a little surprised that no-one else has shown themselves with views similar to mine. All of the arguments you are producing are technically correct, but, IMO, are stretching things a bit. Am I the only person who was, to say the least, 'very surprised' when, many years ago, I first discovered that MCBs were not necessarily even physically interchangeable?

Personally I would have been surprised if MCBs were physically interchangeable. Who would benefit from that? Only the people who were unaware of the possible consequences of making an assembly from multiple manufacturers' products.

BAS is right. They aren't interchangeable John, and the fact that you'd like them to be interchangeable doesn't alter that.

Sure, but everything I have said has been qualified with a caveat about physical compatability in terms of terminals/busbars (and I also agree about the bits protroding through the cover, although that does seem to be pretty standardised). I have indeed suggested that those things could be standardised - but, as you say, they aren't. However, there are a good few that do appear to be physically compatible - and, if they are, I would personaly be comfortable with interchanging them if I had to.Fork busbars vs comb?

Different makes having their entry terminals different distances from the rail, leading to fore-aft or vertical misalignments?

Different depths and/or heights of the parts of the MCBs which protrude through the cover, leading to gaps or the inability to fix the cover in place?

Whatever, I appear to be on a loser here, even though I'm a bit surprised that no-one else has spoken up 'on my side'!

Kind Regards, John.

However, there are a good few that do appear to be physically compatible - and, if they are, I would personaly be comfortable with interchanging them if I had to.

Whatever, I appear to be on a loser here, even though I'm a bit surprised that no-one else has spoken up 'on my side'!

Kind Regards, John.

I've got a headache now. I don't have any paracetamol but never mind, the doctor prescribed some tablets for my wife and they're exactly the same size, so I'll take some of those.

I applaud your grace in defeat!

Fair enough. However, I presume that you are not surprised about the interchangeability of many other electrical items of different makes?Personally I would have been surprised if MCBs were physically interchangeable.

Well, you know my feelings about that. If they truly were compatible, I personally feel that, in the real world' the probability of 'possible consequences' would be incredibly low. However, as I've just written to BAS, I seem to be on a loser hereWho would benefit from that? Only the people who were unaware of the possible consequences of making an assembly from multiple manufacturers' products.

Kind Regards, John.

Correct. No more than I am surprised about the non-interchangeability of other items of electrical equipment. Some things are designed to be interchangeable. Some are not. Simples!Fair enough. However, I presume that you are not surprised about the interchangeability of many other electrical items of different makes?

- Joined

- 17 Aug 2010

- Messages

- 2,741

- Reaction score

- 453

- Country

Whatever, I appear to be on a loser here, even though I'm a bit surprised that no-one else has spoken up 'on my side'!

Well, I did, though only briefly. I'm not sure if this isn't another of those UK special problems, like ring finals.

The domestic CUs I have seen in Germany, 3-phase as you know, were all wired with... wires, not busbars, so the physical dimensions of the contacts were not so important.

And I think that a lot of the type testing requirement in the UK stems from the deviation to BS EN 60439-3 that allows UK Customer Distribution Boards (consumer units) to have a conditional rating of 16kA, providing they are type tested.

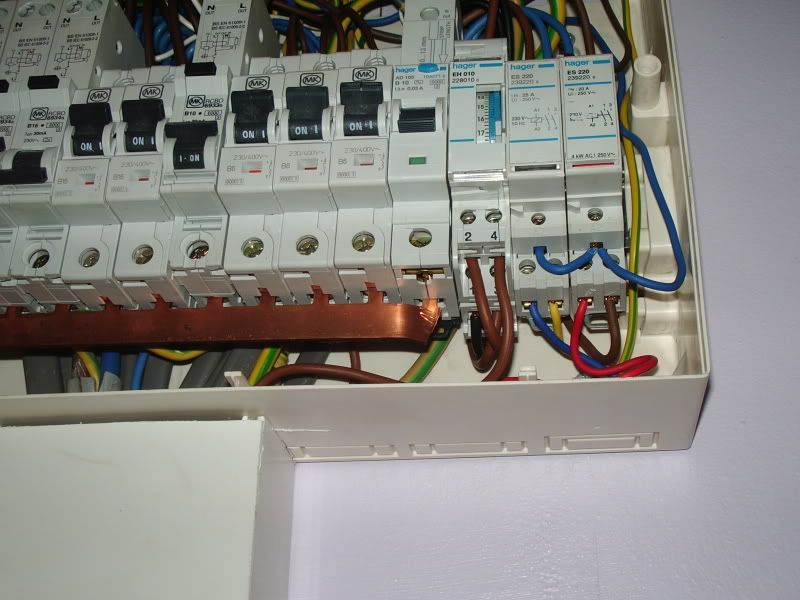

<A photo of a very ungenius modification>

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 18

- Views

- 5K