J

JonasX

I did some looking. Many here have obsessions with unvented cylinders.

- A 200 litre indirect unvented cylinder can be bought for £600 or less.

- An Intergas combi for £850 (can be any combi that can take hot water in the DHW cold inlet [solar preheat which is quite common])

- A bronze pump for £130.

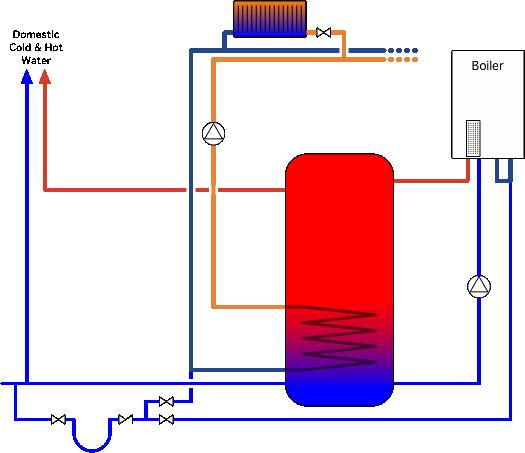

a) Use a combi to heat the cylinder. The Intergas combi, and many others, can receive hot water into the cold inlet. The combi regulates the DHW outlet to temperature to 60C.

b) Use only the hot water section to heat the cylinder. Use a bronze pump on the cold inlet to the combi. The cold inlet is taken off the bottom of the cylinder, either via a Surrey flange or a spare port, which most cylinders have. The hot inlet to the shower connection at the top of the cylinder. Many makes approve of heating a cylinder this way. Do not use the CH section of the combi. Connect CH flow to return and charge up, never to be used. This keeps the heat exchanger squeaky clean if not using say an Intergas combi which effectively has two heat exchangers in one unit. No sludge or sediment gets into the main gas heat exchanger. Combis give higher kw outputs when heating DHW.

The cylinder is now heated top down by 60C water - no blending valve needed. It can give useful water within a minute or so at the taps. It delivers far more DHW than a coil heated cylinder. A cylinder stat can be set to just under 60C.

Fit a time clock for DHW.

c) Use the coil for the CH. There is now a large coil in the cylinder. Use this for the CH take off using a Wilo Smart pump and TRVs on all rads. Have no centralised electric room stat, so all rooms are independently temperature controlled. Fit a sealed system kit on the CH loop. A time clock for the CH. The isolated from the cylinder CH section will not put sludge into the cylinder.

The rads have to be sized to run at a high efficient 60C being very economical heated via an efficient condensing combi.

So what we have is:

1. A pressurized thermal store in which the water is used for DHW purposes, as per usual.

2. It has rapid heat recovery via plate heat exchanger provided by the combi.

3. More DHW is produced than a coil heated unvented cylinder.

4. No boiler cycling.

5. Condensing operation in near 100% of boiler run time

6. Independent temperature control of rooms.

7. It can have full CH & DHW electric backup.

8. The boiler does not cycle reheating the cylinder in one long burn.

9. The main gas heat exchanger stays squeaky clean, as it only heats a plate heat exchanger, raising efficiency.

This a very cheap way to get thermal storage.... and a highly efficient and cheap to run system. Cost effective all around. The comfort conditions are far superior and a higher DHW delivery being heated by a plate heat exchanger.

Why don't we ever see them?

- A 200 litre indirect unvented cylinder can be bought for £600 or less.

- An Intergas combi for £850 (can be any combi that can take hot water in the DHW cold inlet [solar preheat which is quite common])

- A bronze pump for £130.

a) Use a combi to heat the cylinder. The Intergas combi, and many others, can receive hot water into the cold inlet. The combi regulates the DHW outlet to temperature to 60C.

b) Use only the hot water section to heat the cylinder. Use a bronze pump on the cold inlet to the combi. The cold inlet is taken off the bottom of the cylinder, either via a Surrey flange or a spare port, which most cylinders have. The hot inlet to the shower connection at the top of the cylinder. Many makes approve of heating a cylinder this way. Do not use the CH section of the combi. Connect CH flow to return and charge up, never to be used. This keeps the heat exchanger squeaky clean if not using say an Intergas combi which effectively has two heat exchangers in one unit. No sludge or sediment gets into the main gas heat exchanger. Combis give higher kw outputs when heating DHW.

The cylinder is now heated top down by 60C water - no blending valve needed. It can give useful water within a minute or so at the taps. It delivers far more DHW than a coil heated cylinder. A cylinder stat can be set to just under 60C.

Fit a time clock for DHW.

c) Use the coil for the CH. There is now a large coil in the cylinder. Use this for the CH take off using a Wilo Smart pump and TRVs on all rads. Have no centralised electric room stat, so all rooms are independently temperature controlled. Fit a sealed system kit on the CH loop. A time clock for the CH. The isolated from the cylinder CH section will not put sludge into the cylinder.

The rads have to be sized to run at a high efficient 60C being very economical heated via an efficient condensing combi.

So what we have is:

1. A pressurized thermal store in which the water is used for DHW purposes, as per usual.

2. It has rapid heat recovery via plate heat exchanger provided by the combi.

3. More DHW is produced than a coil heated unvented cylinder.

4. No boiler cycling.

5. Condensing operation in near 100% of boiler run time

6. Independent temperature control of rooms.

7. It can have full CH & DHW electric backup.

8. The boiler does not cycle reheating the cylinder in one long burn.

9. The main gas heat exchanger stays squeaky clean, as it only heats a plate heat exchanger, raising efficiency.

This a very cheap way to get thermal storage.... and a highly efficient and cheap to run system. Cost effective all around. The comfort conditions are far superior and a higher DHW delivery being heated by a plate heat exchanger.

Why don't we ever see them?