You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adjustable square that's actually square?

- Thread starter ^woody^

- Start date

D

Deleted member 174758

If you need absolute accuracy then the only solution is to buy an engineer's combination square from a reliable makes such as Moore & Wright, Starrett, Mitutoyo, etc. Problem is that you are well north of £100 on a new one and TBH I think it's way too risky taking something like that on site, although you could always source a secondhand one from fleabay. One nice thing about the good ones (even 60 year old ones) is that you can generally get replacement rules for them up to 24in/600mm long and in metric, too

For general use I carry a couple of Bahco orange combi squares (300 and 400mm) which are checked periodically for squareness, especially if you drop them (also worth checking for damage to the stock as alloy stocks can dent or bend when roughly handled). They were good as purchased, but if you drop them they will go out. The stocks are reasonably heavy and mine are well machined. Most of the cheaper squares on the market aren't even remotely square when new, so I won't touch them.

For anyone reading this who doesn't know how to check for squareness, read this:

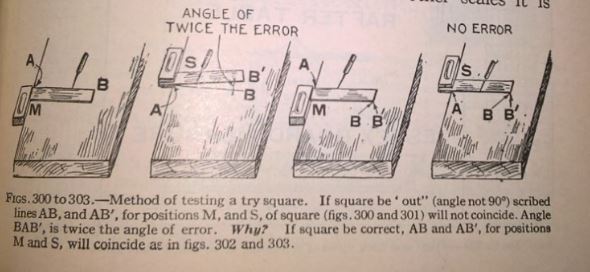

From a carpentry and joinery text first published in 1939. Note that you need to check using the same edge of the ruler because rulers don't always have truly parallel edges (especially on cheap stuff)

For general use I carry a couple of Bahco orange combi squares (300 and 400mm) which are checked periodically for squareness, especially if you drop them (also worth checking for damage to the stock as alloy stocks can dent or bend when roughly handled). They were good as purchased, but if you drop them they will go out. The stocks are reasonably heavy and mine are well machined. Most of the cheaper squares on the market aren't even remotely square when new, so I won't touch them.

For anyone reading this who doesn't know how to check for squareness, read this:

From a carpentry and joinery text first published in 1939. Note that you need to check using the same edge of the ruler because rulers don't always have truly parallel edges (especially on cheap stuff)

I noticed the Bahco square was relatively cheap, so I thought it would not be much good, but that's nice to hear so I may give that one a go.

I recall Rabone ones used to be highly rated, but no longer available.

I got a blue OX square last year to replace an old stanley, but it is crap and I've had enough of it.

I recall Rabone ones used to be highly rated, but no longer available.

I got a blue OX square last year to replace an old stanley, but it is crap and I've had enough of it.

S

SammyInnit

I have a Moore and wright that stays boxed for the exact reason J&K suggested. Expensive but a nice bit of kit if you're into the novel idea of collecting such things.

There is no way I'd be paying over £200 or even £100 for a combi square. Thats just mad. There can not be that much money's worth of engineering in their manufacture. Just a rip off.

I'll stick with my Jack saw and will stretch to a £9.99 Bahco from Amazon!

I'll stick with my Jack saw and will stretch to a £9.99 Bahco from Amazon!

Your just slap dash you Woody!

"Pragmatic" is the word you were looking for.Your just slap dash you Woody!

Contrary to certain people's opinions on my slap dashery, I ordered a set a Bahco's - 400, 300 and 150mm.

They are all dead square, the rules are clear and well engraved, the levels are level (first I have ever known), the scriber screws in so won't get lost after 5 minutes, the knurled adjuster is a joy to grip and use, and they are just quality.

In fact I love the little one so much, we are planning to elope in the new year, and I'm leaving the jack saw behind.

They are all dead square, the rules are clear and well engraved, the levels are level (first I have ever known), the scriber screws in so won't get lost after 5 minutes, the knurled adjuster is a joy to grip and use, and they are just quality.

In fact I love the little one so much, we are planning to elope in the new year, and I'm leaving the jack saw behind.

D

Deleted member 174758

That 400mm is a very handy length to have.

For anyone reading this who doesn't know how to check for squareness, read this:

View attachment 154459

From a carpentry and joinery text first published in 1939. Note that you need to check using the same edge of the ruler because rulers don't always have truly parallel edges (especially on cheap stuff)

If a try square proves to be inaccurate, then I should have thought that the above method - the first section, using the 'flipping over' method - would suffice. Just bisect the angle and use that as the true square!

Yes, a little additional work, but better than shelling out £200!

D

Deleted member 174758

So how exactly will that help me when I'm planing the edge of an 8ft door and want to check that the planed edge is at exactly right angles to the face from end to end (a real world problem, BTW)?If a try square proves to be inaccurate, then I should have thought that the above method - the first section, using the 'flipping over' method - would suffice. Just bisect the angle and use that as the true square!

So how exactly will that help me when I'm planing the edge of an 8ft door and want to check that the planed edge is at exactly right angles to the face from end to end (a real world problem, BTW)?

Easy! Take the door off!

Sorry, joking.

LOL. Square edges.So how exactly will that help me when I'm planing the edge of an 8ft door and want to check that the planed edge is at exactly right angles to the face from end to end (a real world problem, BTW)?

A square square is no good for the closing edge then

D

Deleted member 174758

Two issues there, woody: First off if I'm re-using old doors (listed buildings, etc) it is sometimes necessary to plane in both edges of a panelled door to get it to fit in an existing opening and I do, unfortunately, need at least the hinge side to be square; secondly if you put a leading edge on a door with a mortise lock in it it makes life difficult in terms of getting the lock face to sit right in the door edge, not to mention potentially contravening the latest fire regs which now require the gapping to be no smaller than 2mm and no greater than 4mm. Hence on commercial work we are tending to go back to square edged doors (with the arrisses knocked off) which can be a royal PIA. So having a square that's off by a few degrees really doesn't help the situation IMHO

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 3

- Views

- 1K

D

- Replies

- 13

- Views

- 1K

D