I

iateyoubutler

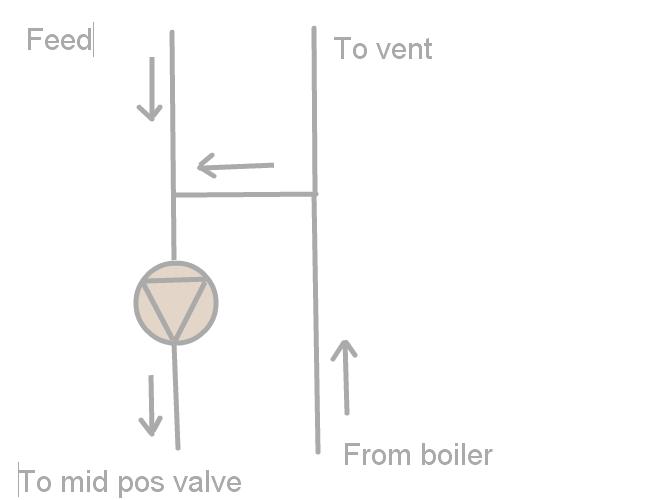

I have heard air coming out of it, but it happens very rarely. I would imagine, that it being where it is the air would just go straight past it rather than out of it? I`m starting to come to the conclusion now that the whole thing is badly laid out, which is why I was talking above about starting againIs the air bottle / auto vent working properly ? it's the only place for air to escape the coil