Hi there,

I'm fairly hands-on and I'm building myself a sliding driveway gate out of timber this winter. My granddad was a joiner and he's taught me a few things, but I'm no expert so wanted to run my plan by the more experienced guys in this group.

My rough plan:

The aim is something more functional than beautiful. You see the pro's build some really beautiful gates, but then I love the simplicity of this French one. They don't have to be so complicated I guess!

A few questions if I may:

1) Timber-wise, I was going to go for vac treated CLS timber for the frame rather than the "fencing grade timber" my local merchant has in stock. I'm hoping CLS will be a little straighter over a 6m length. I'm planning to give it some coats of Sikkens in the spring once it's dried out. Is this a good plan?

2) For Joints, I was going to use a pocket hole jig and keep it simple rather than trying to learn how to make more complicated joints. Will they be sufficient, with PU glue too?

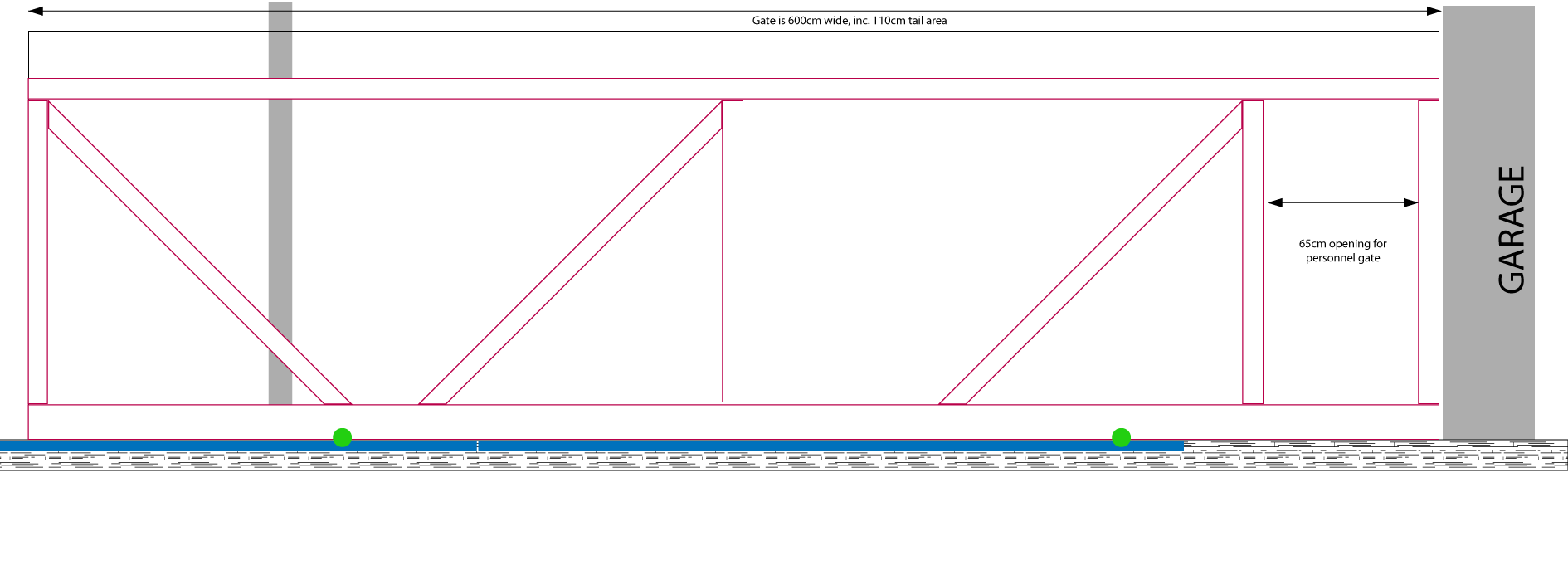

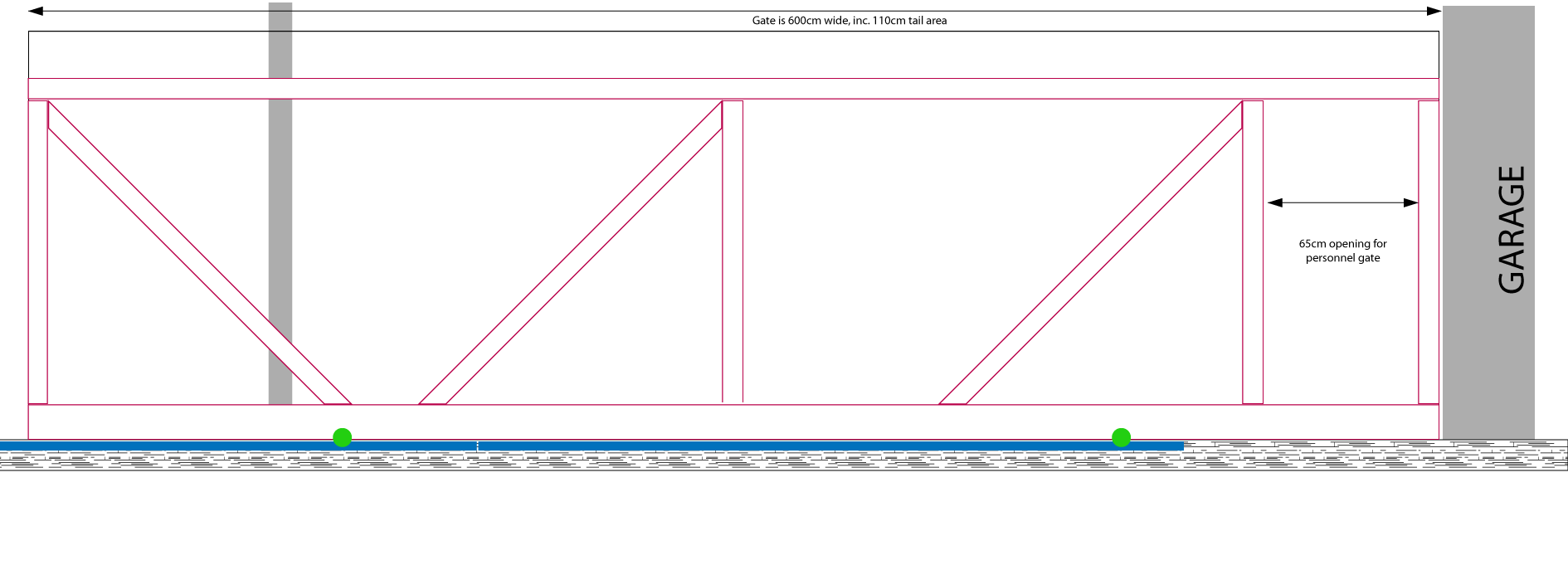

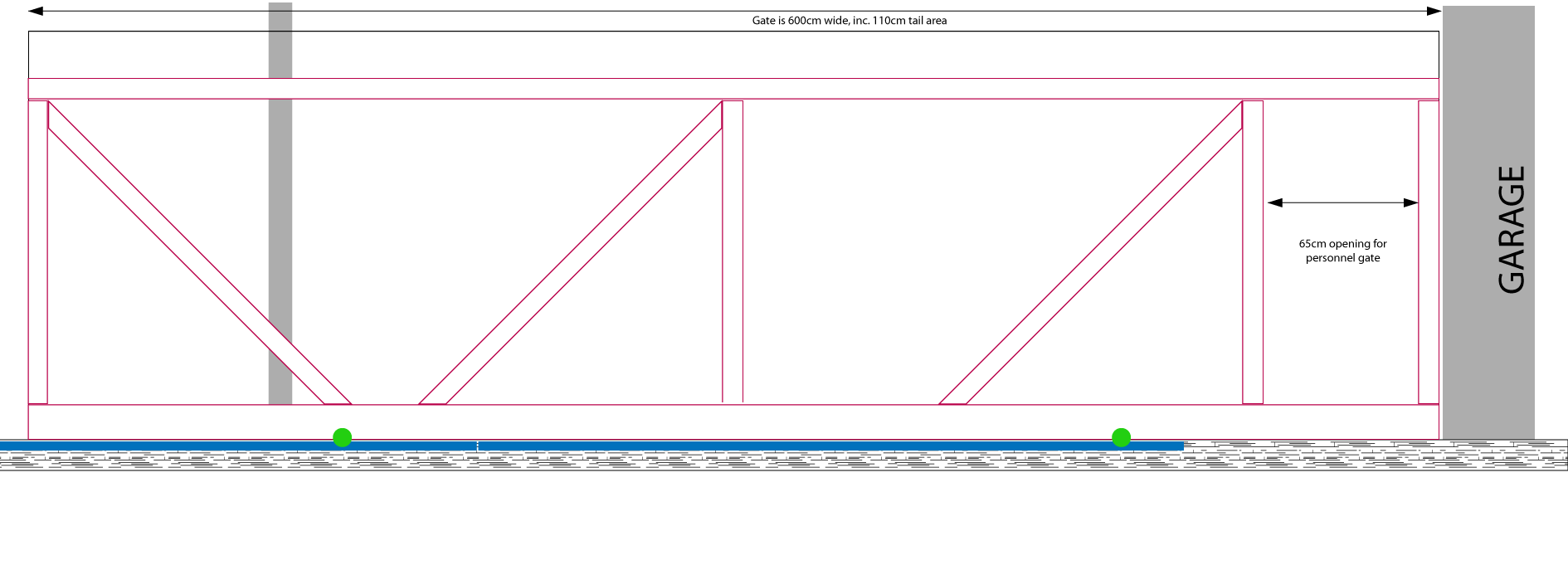

3) My plan for the frame looks like this:

Not as simple as the French gate, but not overly complex either. It'll be 4"x2" all round, but 6"x2" for the bottom edge that takes the wheels.

At the end of the day I suppose the job of the frame is just to hold the feather edge boards in place! Being supported by wheels means it's less likely to sag than a swing gate I guess, although I'm tempted to run a length of 50mm galvanized steel angle under the bottom edge, as I have one spare.

Is there anything I should improve here?

I'm fairly hands-on and I'm building myself a sliding driveway gate out of timber this winter. My granddad was a joiner and he's taught me a few things, but I'm no expert so wanted to run my plan by the more experienced guys in this group.

My rough plan:

- A 6m wide sliding gate

- Motor, electrics, track, etc. already in place

- Timber frame with feather edge boards to the front, to match the surrounding fence panels

The aim is something more functional than beautiful. You see the pro's build some really beautiful gates, but then I love the simplicity of this French one. They don't have to be so complicated I guess!

A few questions if I may:

1) Timber-wise, I was going to go for vac treated CLS timber for the frame rather than the "fencing grade timber" my local merchant has in stock. I'm hoping CLS will be a little straighter over a 6m length. I'm planning to give it some coats of Sikkens in the spring once it's dried out. Is this a good plan?

2) For Joints, I was going to use a pocket hole jig and keep it simple rather than trying to learn how to make more complicated joints. Will they be sufficient, with PU glue too?

3) My plan for the frame looks like this:

Not as simple as the French gate, but not overly complex either. It'll be 4"x2" all round, but 6"x2" for the bottom edge that takes the wheels.

At the end of the day I suppose the job of the frame is just to hold the feather edge boards in place! Being supported by wheels means it's less likely to sag than a swing gate I guess, although I'm tempted to run a length of 50mm galvanized steel angle under the bottom edge, as I have one spare.

Is there anything I should improve here?

Last edited: