Hello and thanks in advance for any help.

Firstly, I have searched both here and more widely and I’m struggling to find a complete answer – apologies if this has been done to death. Hopefully a fairly simple question regarding adding a radiator to a pressurised S-plan system prior to the CH / HW split or on the return.

We want to add a rad to our kitchen as the dimensions are 5 x 6 with a huge window and the ceiling height is over 4m. Currently this is ‘heated’ solely by a 1800*450mm vertical rad which I’d estimate at 1250-1500 watts. Unfortunately, the floor is a rather lovely engineered wood type which after some prying appears to be glued together. Thus teeing off the main CH circuit will be next to impossible. The boiler is in the kitchen close to where we’d like to put an extra rad. I’m trying to understand the feasibility of teeing from the main flow & return. Diagram and questions below:

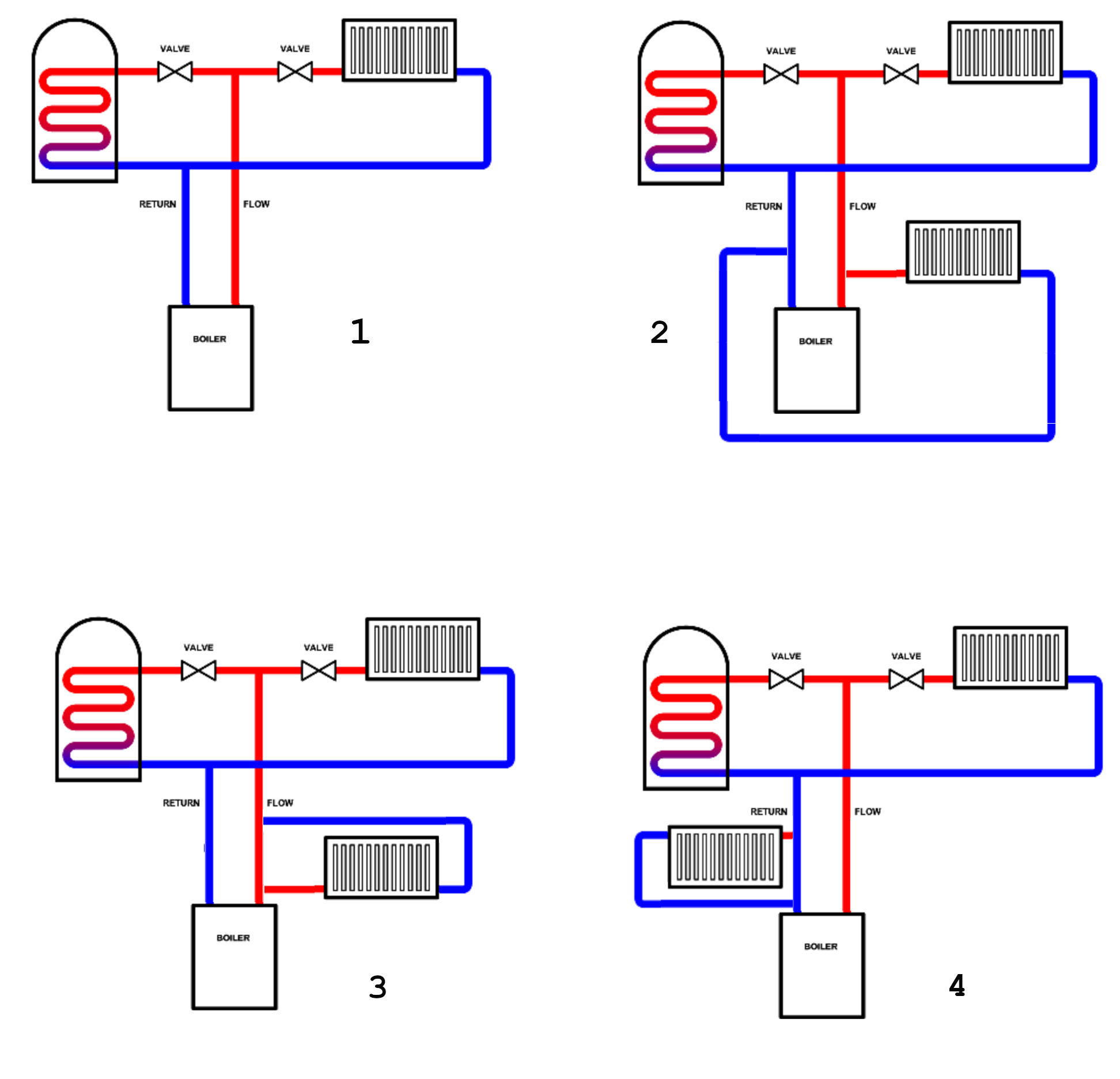

1. Current simplified system.

2. Tee from flow and return. Issue as I understand it is the heat into the return causing the boiler to short cycle.

3. Tee from flow only. Struggled to find much about this.

4. Tee from return only. Struggled to find much about this.

If 3 or 4 were viable I’d look to control the rad with an additional programmable thermostat so that it can be switched off when the hot water is being heated. Thanks for any help and apologies for the noddy questions.

Firstly, I have searched both here and more widely and I’m struggling to find a complete answer – apologies if this has been done to death. Hopefully a fairly simple question regarding adding a radiator to a pressurised S-plan system prior to the CH / HW split or on the return.

We want to add a rad to our kitchen as the dimensions are 5 x 6 with a huge window and the ceiling height is over 4m. Currently this is ‘heated’ solely by a 1800*450mm vertical rad which I’d estimate at 1250-1500 watts. Unfortunately, the floor is a rather lovely engineered wood type which after some prying appears to be glued together. Thus teeing off the main CH circuit will be next to impossible. The boiler is in the kitchen close to where we’d like to put an extra rad. I’m trying to understand the feasibility of teeing from the main flow & return. Diagram and questions below:

1. Current simplified system.

2. Tee from flow and return. Issue as I understand it is the heat into the return causing the boiler to short cycle.

3. Tee from flow only. Struggled to find much about this.

4. Tee from return only. Struggled to find much about this.

If 3 or 4 were viable I’d look to control the rad with an additional programmable thermostat so that it can be switched off when the hot water is being heated. Thanks for any help and apologies for the noddy questions.