Hi,

Here I am again, this time refurbishing a downstairs toilet, which should be much easier than my 1 year elapsed bathroom refurbishment!

I'm installing the same Geberit Duofix frame and Duravit floating toilet that I installed in the bathroom and I'm having issues with the position of the existing soil pipe, which I expected to have to resolve, but would appreciate your expertise on the best way (and most economical way) to do this.

Here's a photo of the position I want to install the Geberit frame in the toilet:

As you can see the existing soil pipe position is too low and is slightly off-centre. The original toilet was installed off-centre for some unknown reason - probably laziness or lack of professionalism! Rough measurements suggest it needs to be raised by around 50mm and moved to the right by about 30mm.

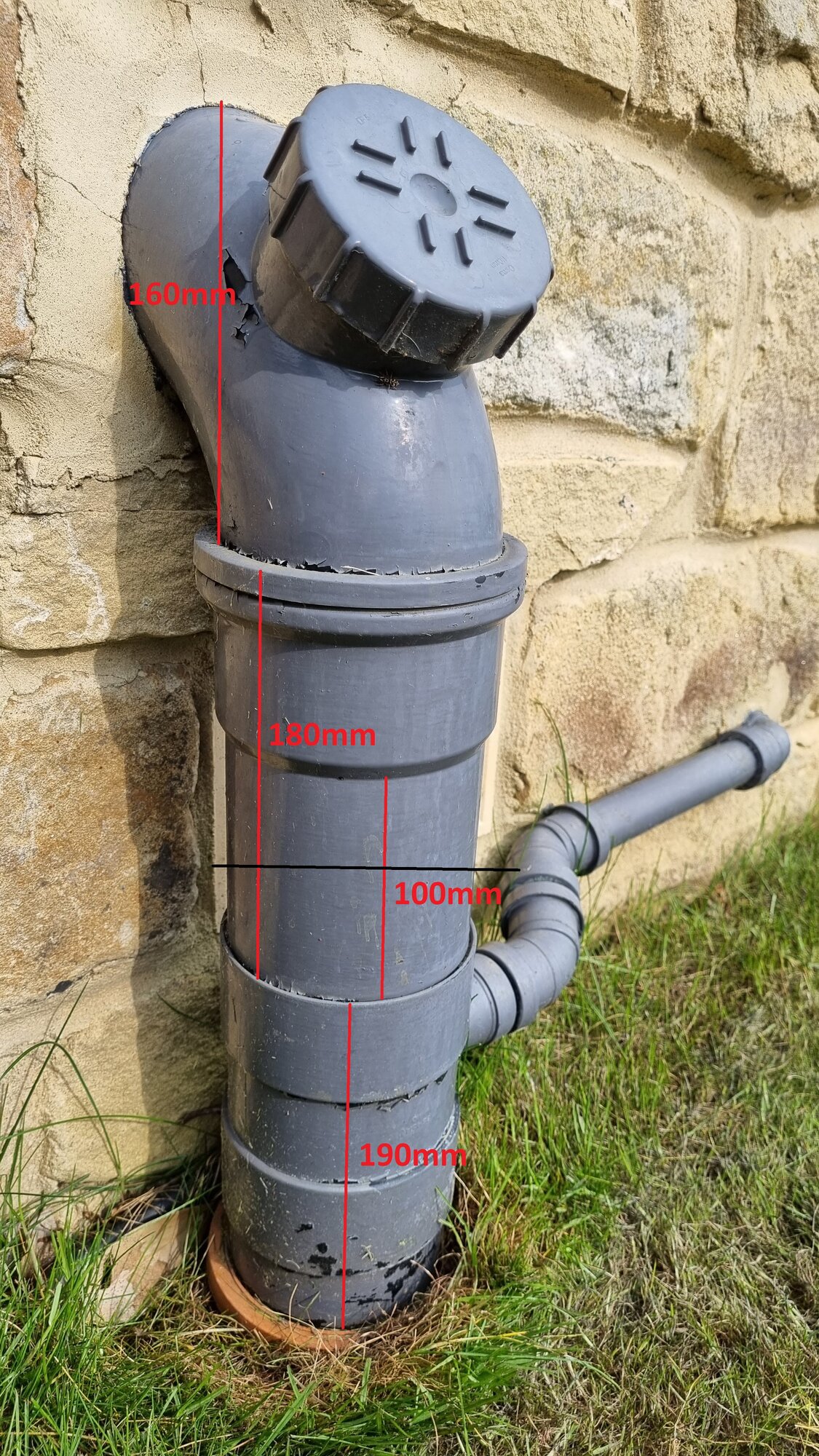

So, my plan was to remove the existing soil pipe and expand the size of the hole to allow it to be moved into the required position. However, this obviously can't be done without also doing some work to the soil pipes outside, which look like this:

Fortunately, I don't believe I need to move the vertical soil pipe (left or right), just simply swivel it to the left as it enters the house and this should make it more central inside as at the moment it comes in at a slight angle. In terms of height, I will need to somehow lift it up around 50mm. The vertical pipe from the boss attachment is solvent welded, but the 90 deg bend uses pushfit. I need to increase the length of the straight piece of pipe from 100mm to 150mm, possibly less to include a fall away from the toilet pan.

I think I can achieve this by cutting the pipe half way along (where the horizontal black line is shown), leaving 2 x 50mm straights, which I can then re-connect with a coupler, which will increase the length.

The pipes are Wavin Osmasoil 110mm and Wavin make a solvent weld coupler, which is 155mm long and allows 50mm straights to be slotted into each end. So, as far as I understand, this would increase the height by 55mm? A little more than I need so this may not work. Wavin also make a push fit coupler, which is only 150mm long, so possibly a better length, but more "bulky". I could potentially replace the 90 deg access bend with a push fit version and replace the top straight, which includes the pushfit, with a piece of straight pipe. One end of the straight pipe would fit into the coupler and the other end into the push fit side of the 90 deg bend. I'm assuming the bend can be installed either way (pushfit vertical or horizontal). Doing this, would allow me to cut the straight pipe to the required length i.e. around 50mm plus the 50mm for the solvent welded end and whatever is required to fit into the pushfit side of the elbow.

Now that I've probably completely confused you, I would appreciate any feedback on my "plan" or guidance on how there might be a better way to achieve the required end result.

Here I am again, this time refurbishing a downstairs toilet, which should be much easier than my 1 year elapsed bathroom refurbishment!

I'm installing the same Geberit Duofix frame and Duravit floating toilet that I installed in the bathroom and I'm having issues with the position of the existing soil pipe, which I expected to have to resolve, but would appreciate your expertise on the best way (and most economical way) to do this.

Here's a photo of the position I want to install the Geberit frame in the toilet:

As you can see the existing soil pipe position is too low and is slightly off-centre. The original toilet was installed off-centre for some unknown reason - probably laziness or lack of professionalism! Rough measurements suggest it needs to be raised by around 50mm and moved to the right by about 30mm.

So, my plan was to remove the existing soil pipe and expand the size of the hole to allow it to be moved into the required position. However, this obviously can't be done without also doing some work to the soil pipes outside, which look like this:

Fortunately, I don't believe I need to move the vertical soil pipe (left or right), just simply swivel it to the left as it enters the house and this should make it more central inside as at the moment it comes in at a slight angle. In terms of height, I will need to somehow lift it up around 50mm. The vertical pipe from the boss attachment is solvent welded, but the 90 deg bend uses pushfit. I need to increase the length of the straight piece of pipe from 100mm to 150mm, possibly less to include a fall away from the toilet pan.

I think I can achieve this by cutting the pipe half way along (where the horizontal black line is shown), leaving 2 x 50mm straights, which I can then re-connect with a coupler, which will increase the length.

The pipes are Wavin Osmasoil 110mm and Wavin make a solvent weld coupler, which is 155mm long and allows 50mm straights to be slotted into each end. So, as far as I understand, this would increase the height by 55mm? A little more than I need so this may not work. Wavin also make a push fit coupler, which is only 150mm long, so possibly a better length, but more "bulky". I could potentially replace the 90 deg access bend with a push fit version and replace the top straight, which includes the pushfit, with a piece of straight pipe. One end of the straight pipe would fit into the coupler and the other end into the push fit side of the 90 deg bend. I'm assuming the bend can be installed either way (pushfit vertical or horizontal). Doing this, would allow me to cut the straight pipe to the required length i.e. around 50mm plus the 50mm for the solvent welded end and whatever is required to fit into the pushfit side of the elbow.

Now that I've probably completely confused you, I would appreciate any feedback on my "plan" or guidance on how there might be a better way to achieve the required end result.

Last edited: