First off I hope I am posting in the right section.

Second, I have a 2 post lift that I am having issues with. The control board was damaged and we ordered one in. It is a German lift, not THAT old but not sold anymore. The company got what they thought was the correct board in and we fitted it.

All was okay til the lift went out of sync. There is a reset proceedure involving both up and down buttons (which are low voltage). A massive bang happened and the breaker went.

What has happened is the original board had a physical interlock on the reverse contactor. The replacement doesn't, I think it has an electrical one.

Anyway both relays inside the reverse contactor have managed to fire at the same time resulting in the bang.

I'm a bit sick of buying incorrect £600 boards so thinking of making my own.

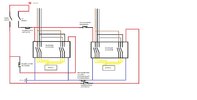

See the diagram. The only issues I can see is the board syncronised the lifts for you, i.e if one slowed down a little because the car was slightly off center it would stop one lift momentarily and balance it.

So I have added a normaly closed switch to motor 2 so we can do that ourselves.

Seems a shame to get rid of the lift as it came from a commercial VW dealer and it will cost £10k to get one that is this solid. We can get a Smart Car or a LWB Luton Sprinter on and the legs are so heavy duty it doesn't wobble with the heavy stuff on.

Thanks for your thoughts.

Second, I have a 2 post lift that I am having issues with. The control board was damaged and we ordered one in. It is a German lift, not THAT old but not sold anymore. The company got what they thought was the correct board in and we fitted it.

All was okay til the lift went out of sync. There is a reset proceedure involving both up and down buttons (which are low voltage). A massive bang happened and the breaker went.

What has happened is the original board had a physical interlock on the reverse contactor. The replacement doesn't, I think it has an electrical one.

Anyway both relays inside the reverse contactor have managed to fire at the same time resulting in the bang.

I'm a bit sick of buying incorrect £600 boards so thinking of making my own.

See the diagram. The only issues I can see is the board syncronised the lifts for you, i.e if one slowed down a little because the car was slightly off center it would stop one lift momentarily and balance it.

So I have added a normaly closed switch to motor 2 so we can do that ourselves.

Seems a shame to get rid of the lift as it came from a commercial VW dealer and it will cost £10k to get one that is this solid. We can get a Smart Car or a LWB Luton Sprinter on and the legs are so heavy duty it doesn't wobble with the heavy stuff on.

Thanks for your thoughts.