- Joined

- 28 Jul 2014

- Messages

- 1,969

- Reaction score

- 566

- Country

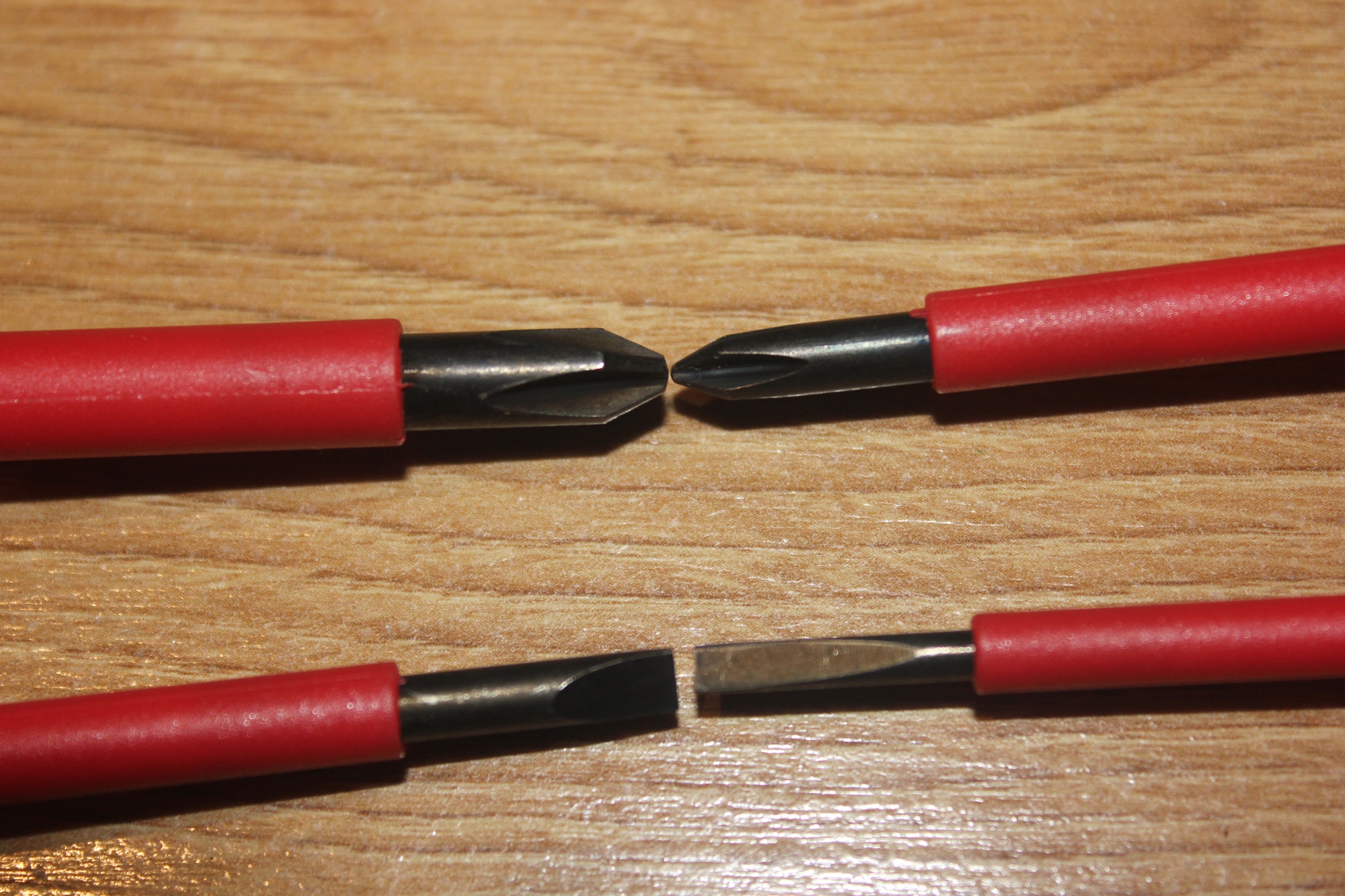

you really need both PH and PZ style

Agreed, too many people think they are the same thing.

On a budget, for only 15 quid, this screwdriver set has Phillips and Pozi and a few slotted...

http://www.ebay.co.uk/sch/AK6124

...and you could have spent the other 15 quid on some cutters/pliers...

http://www.ebay.co.uk/sch/5023969305257

(OK, just over budget at 18 quid, but I was desperate to find a set that doesn't say Silverline or Am-tech or Dekton on them, as they're all utter carp)

Gaz