Hi,

I am working on fitting out a new floor extension on a typical Swiss 'bunker style' from 1970s with reinforced concrete slabs. I need to drill some holes to take 110mm soil pipes, and heating loops etc through two existing concrete floors. These floors are 200-250mm thick, and have a mix of 10 & 14mm roobar in them.

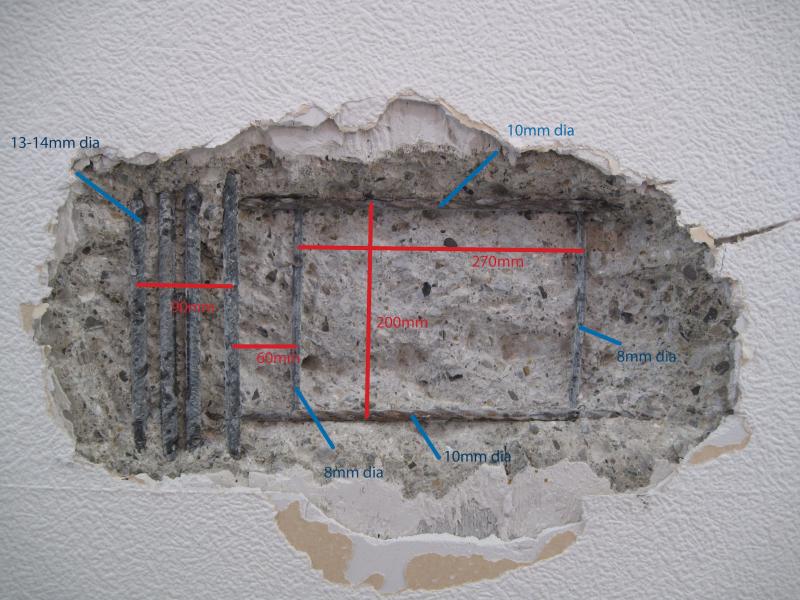

Attached is picture of an exposed part of construction. Please note this shows slab at a critical point near structural wall. Where I'll be drilling doesn't have same density of bars. I've checked with architect that it's ok to make holes where I plan.

Previously I made a 150mm hole using a circle of 12mm bit, but it took a very long time. I was quoted CHF 3400, nearly 2000 pounds to drill these 8-10 holes by a Swiss masonry company who did lots of the work on extension. And before you ask they are relatively cheap and good compared to others here - it's just that small jobs are very expensive....

I could fly someone out on holiday for that price, but instead I'm looking at buying a proper core drill, doing myself and selling after (hiring is not option here as very few people do DIY).

Looking on the Bosch site, it looks like these combination would be suitable for job:

Bosch GBH 7-46: http://www.bosch-professional.com/gb/en/gbh-7-46-de-8848-ocs-p/

Will do cores up to 150mm diam, about 500 pounds on ebay.

Bosch diamond bit: http://www.ebay.co.uk/itm/BOSCH-F00...Home_Garden_PowerTools_SM&hash=item3367d61713

Too big but I can probably source another one of right size.

Much cheaper ELU TCT bit: http://www.ebay.co.uk/itm/ELU-E3351...Home_Garden_PowerTools_SM&hash=item4aa814b2e5

Anyone have some thoughts on this - as I will be back in UK soon I want to make sure I get right kit rather than have to buy at inflate prices here.

I assume a proper diamond core bit is required, and the TCT one will just wear out?

Are there better makes/models than this Bosch one?

Whatever I get will probably wind up on eBay once all the work is done, so the resale value is also a factor.

Thanks very much

Rick

I am working on fitting out a new floor extension on a typical Swiss 'bunker style' from 1970s with reinforced concrete slabs. I need to drill some holes to take 110mm soil pipes, and heating loops etc through two existing concrete floors. These floors are 200-250mm thick, and have a mix of 10 & 14mm roobar in them.

Attached is picture of an exposed part of construction. Please note this shows slab at a critical point near structural wall. Where I'll be drilling doesn't have same density of bars. I've checked with architect that it's ok to make holes where I plan.

Previously I made a 150mm hole using a circle of 12mm bit, but it took a very long time. I was quoted CHF 3400, nearly 2000 pounds to drill these 8-10 holes by a Swiss masonry company who did lots of the work on extension. And before you ask they are relatively cheap and good compared to others here - it's just that small jobs are very expensive....

I could fly someone out on holiday for that price, but instead I'm looking at buying a proper core drill, doing myself and selling after (hiring is not option here as very few people do DIY).

Looking on the Bosch site, it looks like these combination would be suitable for job:

Bosch GBH 7-46: http://www.bosch-professional.com/gb/en/gbh-7-46-de-8848-ocs-p/

Will do cores up to 150mm diam, about 500 pounds on ebay.

Bosch diamond bit: http://www.ebay.co.uk/itm/BOSCH-F00...Home_Garden_PowerTools_SM&hash=item3367d61713

Too big but I can probably source another one of right size.

Much cheaper ELU TCT bit: http://www.ebay.co.uk/itm/ELU-E3351...Home_Garden_PowerTools_SM&hash=item4aa814b2e5

Anyone have some thoughts on this - as I will be back in UK soon I want to make sure I get right kit rather than have to buy at inflate prices here.

I assume a proper diamond core bit is required, and the TCT one will just wear out?

Are there better makes/models than this Bosch one?

Whatever I get will probably wind up on eBay once all the work is done, so the resale value is also a factor.

Thanks very much

Rick

Links in this post may contain affiliate links for which DIYnot may be compensated.