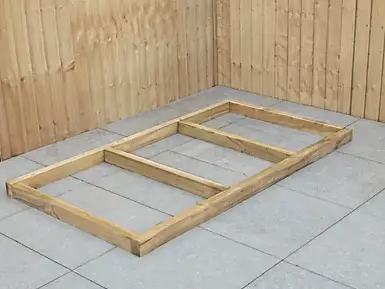

I am planning a lean-to shed that is around 3m x 60cm. It will be sitting on a concrete base that is already there. I am considering this type of frame which then has an OSB Board over it:

This OSB board will then be the floor of my shed when accessed from inside. I think it's a good idea to raise the floor of the shed as it removes the risk of surface water penetrating the shed. Let me know if you think any different?

I am concerned that these timbers will rot as water will seep through and get into this space when it rains. I could lay it over a section of rood membrane but would appreciate any advice around this. Since everything will be erected on this, it will be a mare to replace the floor at a later date.

Thanks in advance.

This OSB board will then be the floor of my shed when accessed from inside. I think it's a good idea to raise the floor of the shed as it removes the risk of surface water penetrating the shed. Let me know if you think any different?

I am concerned that these timbers will rot as water will seep through and get into this space when it rains. I could lay it over a section of rood membrane but would appreciate any advice around this. Since everything will be erected on this, it will be a mare to replace the floor at a later date.

Thanks in advance.