I have a Worcester Highflow 440CDi and have added some temp sensors to the flow/return pipes for monitoring purposes (or geeky interest - whichever  ). Here is a graph from last night...

). Here is a graph from last night...

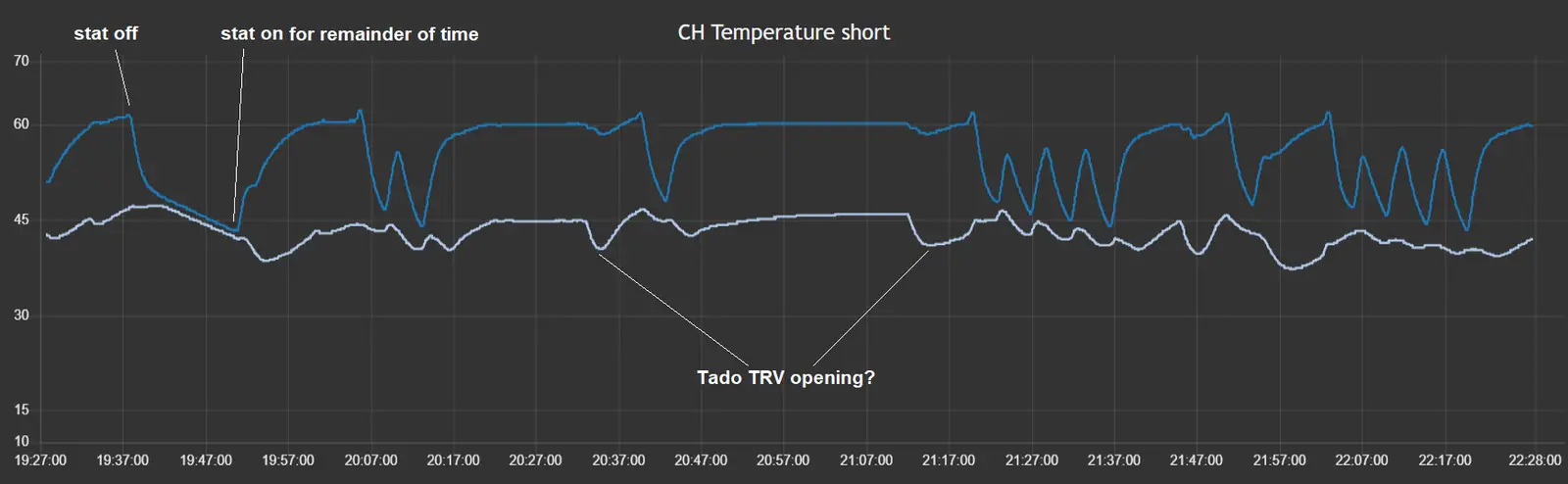

Dark blue - flow, light blue - return

It is currently set to 60C flow temp which it holds very well until there is a disturbance in the system like a tado TRV opening up a radiator. It seems to initially handle that but then leads to the flow temp going over the 60C and the boiler turns off. When it comes back on a few minutes later, the flow temp rises but sometimes cycles on and off a few times before stabilising. I'm wondering if this is down to the lag in the system - it takes a while for the return to start rising after the boiler fires, is the boiler looking for that rise in return and giving up too soon? Are there any parameters that can be tweaked? {edit: looking at the service manual there doesn't seem to be any return temp sensor so it must control off the flow temperature)

Dark blue - flow, light blue - return

It is currently set to 60C flow temp which it holds very well until there is a disturbance in the system like a tado TRV opening up a radiator. It seems to initially handle that but then leads to the flow temp going over the 60C and the boiler turns off. When it comes back on a few minutes later, the flow temp rises but sometimes cycles on and off a few times before stabilising. I'm wondering if this is down to the lag in the system - it takes a while for the return to start rising after the boiler fires, is the boiler looking for that rise in return and giving up too soon? Are there any parameters that can be tweaked? {edit: looking at the service manual there doesn't seem to be any return temp sensor so it must control off the flow temperature)

Last edited: