- Joined

- 29 Jan 2010

- Messages

- 28

- Reaction score

- 1

- Country

Hi Everyone

2nd post on here! This has proved to be quite a saga so hopefully the experienced posters here can help me out

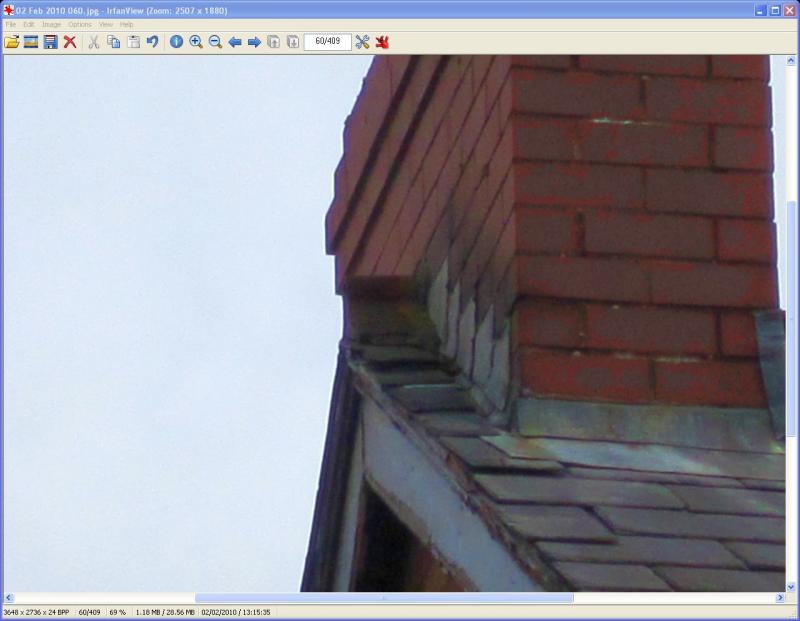

I’ve got some crumbling bricks on my chimney breast. It has been getting worse over the last 6 or so years. I have had various people look at it but nobody is sure what is causing it.

I have 4 flues and these are now unused. One flue has no pot and has been cemented over. The other 3 have caps on.

I think it could be something to do with the Chimney as it seems to follow the line of the flues down one side. If it was just general weathering I would have thought the bricks affected would have been more random.

When I look at the chimney breast inside the loft, I can see that the mortar is dry directly below the lead tray, but as you go down the mortar gets very damp and crumbly. I have tested this on the damp meter. (see photo. Red arrows point out damp mortar)

The flashing was replaced last year on the roof side of the chimney and I was told the flashing was ok on the other hard to get at side, but I am not sure if it is. I have blown up some photos of it from the garden and it looks ok. The builder who did this repair also re-pointed the weathered bricks with normal cement. This can be seen in the pics. I understand now that using lime mortar would have been better. They also washed the white residue off the bricks and then washed them down with a hose.

I think that the damp mortar inside the house in the loft might indicate that water is getting inside the chimney and finding it’s way out through the bricks on the outside leading to the bricks getting attacked.

A possibilty also is that the rain water is getting down the outside of the chimney, running between the chimney and the roof then down the chimney breast. Maybe the problem wouldn’t follow the track to the left side if this was happening though?

I notice that the bricks are being attacked right up under the eves, which shouldn’t get much weather, further indicating a problem from above maybe?

Has anyone seen a problem like this on a 1920’s red brick house? Is there any way to diagnose it accurately?

What about removing some bricks from the chimney breast inside to get a look at what’s going on inside the chimney?

Any ideas?

Sorry for the long post but I felt some detail was necessary.

Cheers, Andy