Sorry to harp on about my CH problems again.

My boiler (Viessmann Vitodens 100C) is only firing occasionally, and never reaches full temperature of 80C on the maximum setting (it has, in the past, reached 75C). Even using just the nearest rad (upstairs), the boiler heats up from 41C to 64C in about a minute using 2 bars of a possible 5. It then drops back to 41C in about 4 minutes before firing again. I think this is due to airlocks in my system.

When I start up, there is a lot of whooshing and gurgling and water is taken from the feed. Some of the radiators gurgle. It sounds as if there is air in them even though I have bled them many times. One rad managed to hiss a bit of air from the vent after I banged it all over with with a rubber mallet, suggesting it had several locked pockets of air.

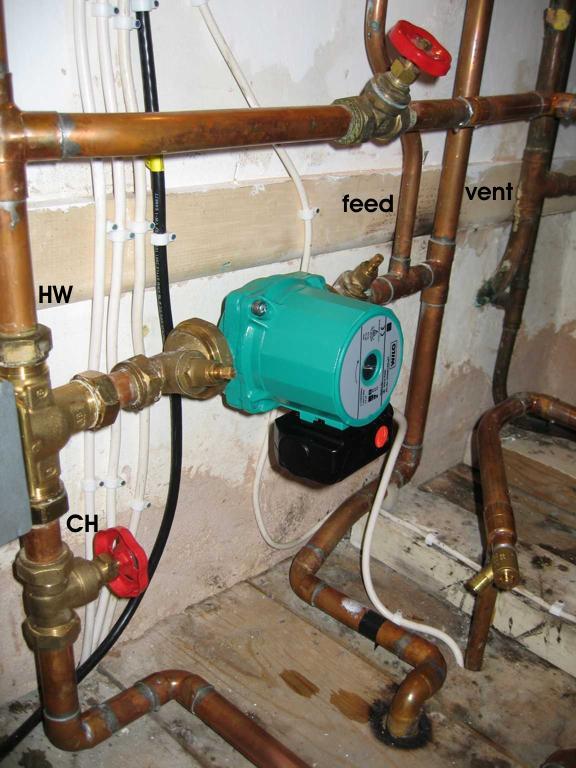

When I switch off the system and the pump stops, there is again a lot of gurgling in the pipes - particularly round the pump, mid-position valve and HW cylinder. I have bled the vent near the pump (a self-venting Wilo Yonos Pico) and the Magnaclean near the boiler. I don't know how to get at the air remaining in the system.

I think that there are pockets of air in the system that compress when the pump starts and water is drawn in from the F&E pipe. When the pump stops after switching off, the air pockets expand again pushing water up the F&E pipe. Both events are noisy.

Any suggestions? The current temperature that the radiators reach (after a long time) will not be adequate in freezing weather, so my plan to limp through until next summer may not be practical.

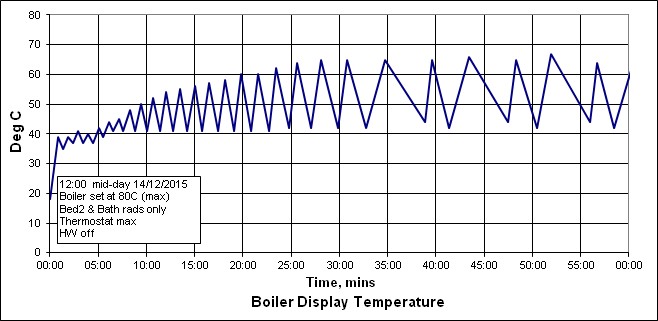

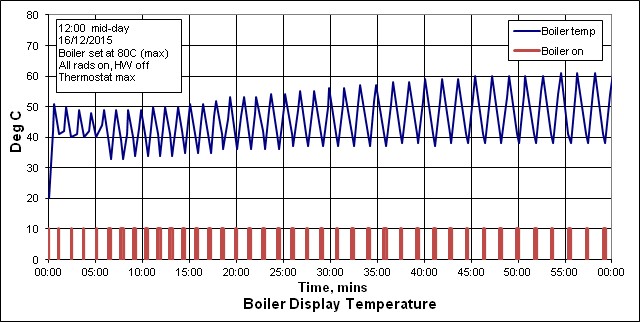

The following boiler temperature plots show what is happening.

The first is with only the two nearest rads upstairs, so no effects from ground floor drops. I have only recorded the boiler on/off temperatures and joined them with straight lines:

The second is with all rads on. I have added the boiler on/off periods (on for only 25% of the time). After 5 minutes, I also recorded the lowest temperature reached a few seconds after the boiler fired up: