- Joined

- 27 Jan 2008

- Messages

- 28,038

- Reaction score

- 3,403

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

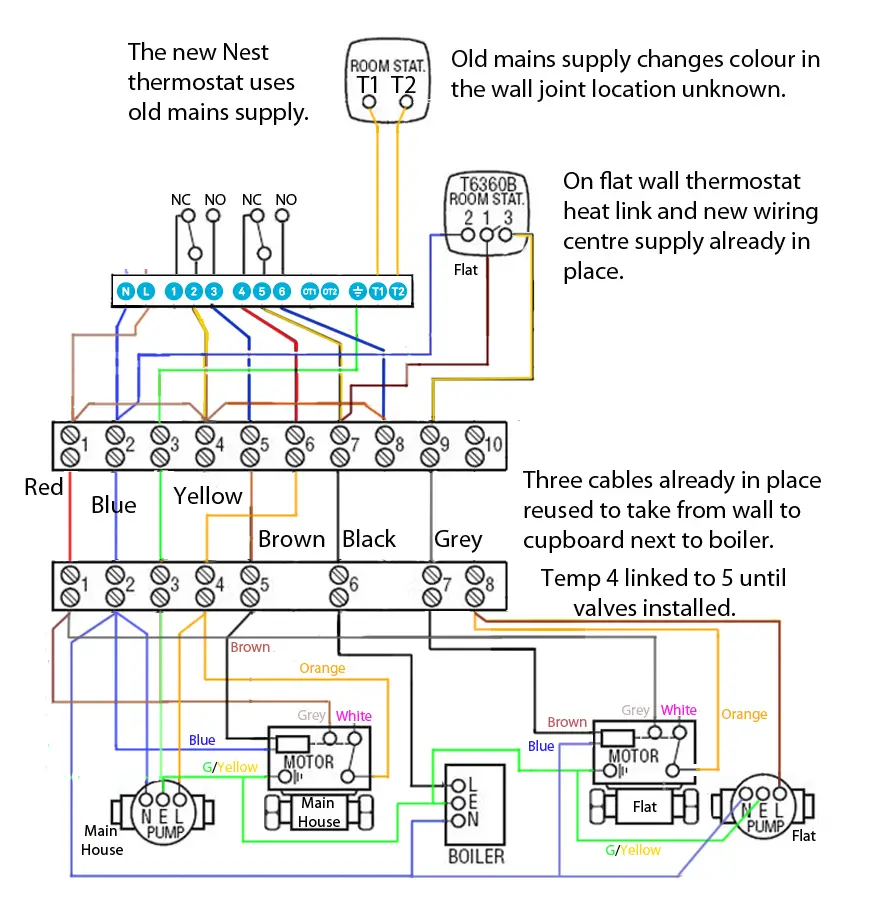

Well latter today the plumber is due to arrive to complete the work, the gap has been good as been able to iron out some problems. If using two pumps this

diagram was to be used, however with a single pump this

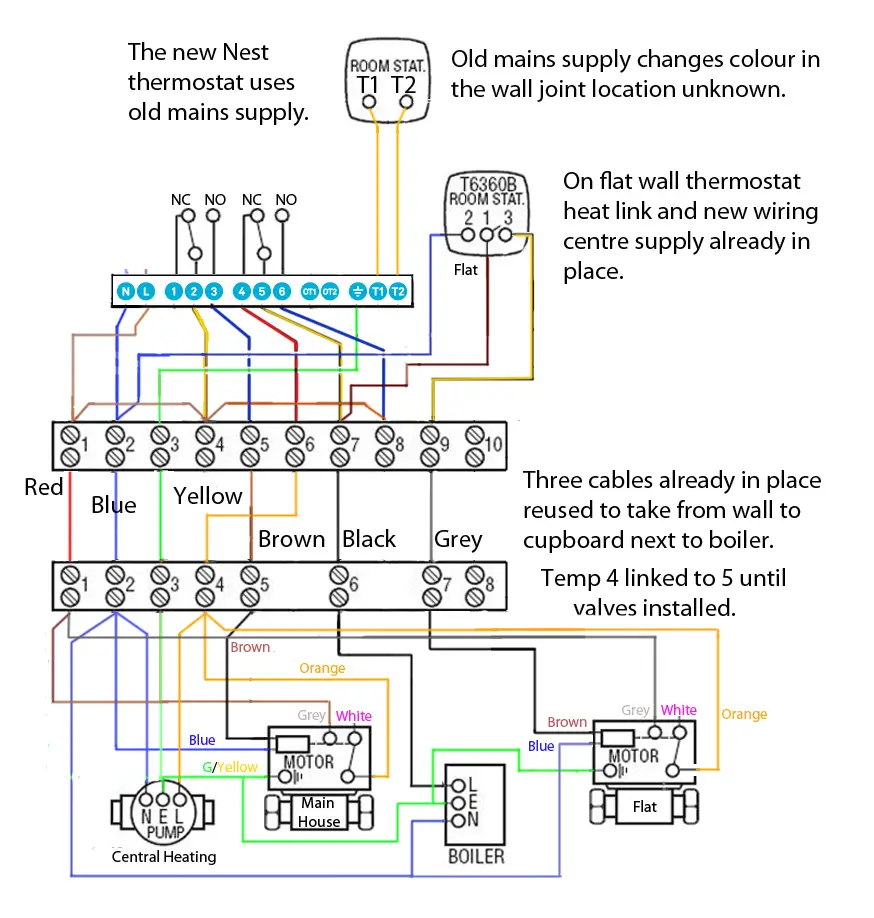

diagram was to be used, however with a single pump this

this actually works better giving full central heating control in the flat.

this actually works better giving full central heating control in the flat.

Also the problem with random boiler firing has been solved, it was not a fault, why the help lines did not point this out I don't know? However I in the end found the following

During winter there is no problem, however in summer maybe it needs an extra boost every so often to stop legionnaires? but not sure about every 48 hours? Tried to read through HSE web site, and it does talk about temperatures, however a standard (not Irish) system heat the water at the top, but not bottom of cistern, so there will always be a layer where the water is between 20°C and 50°C and no amount of running boiler or immersion heater will ensure whole tank at over 50°C so unless top of tank always above 50°C then one can never be sure.

Also the problem with random boiler firing has been solved, it was not a fault, why the help lines did not point this out I don't know? However I in the end found the following

so it seems no fault, I have turned off the feature to prove that is why it random fired up, but I am reasonably sure that was the cause of what I saw as a problem.Google Nest Help said:How the Nest thermostat helps prevent Legionella bacteria

Legionnaires’ disease is a potentially fatal type of pneumonia that’s contracted by inhaling water droplets that contain Legionella bacteria. The 3rd gen Google Nest Thermostat’s Bacteria Prevention feature works with both On/Off hot water systems and OpenTherm hot water system boilers. To help prevent bacterial growth, it will heat your hot water tank even if your home is in Away mode.

Legionella bacteria can develop in water that has been exposed to impurities like rust, algae and limescale, in temperatures between 20 and 45 °C. The bacteria are dormant below 20 °C and do not survive above 60 °C (Source: HSE UK).

Bacteria Prevention is an exclusive feature of 3rd gen Nest Learning Thermostats. Bacteria Prevention mode will activate if your domestic water hasn’t been heated for at least 2 consecutive hours in the last 48 hours. This can happen if there is a gap of more than 48 hours in your hot water heating schedule or if you are away from home for longer than 48 hours. For instance, if you have a second home or holiday home and only need hot water for weekends, you can create a hot water schedule for Saturday and Sunday, and the Bacteria Prevention mode will automatically heat the hot water tank during the week.

">Learn about Home/Away Assist >

">How to switch your home to Away or Home mode manually >

Your Nest thermostat will let you know Bacteria Prevention mode is running by showing you a water droplet inside of a circleon the temperature screen.

Note: The Bacteria Prevention icon(water drop with circle) is different than the hot water boost icon (no circle). To learn about these or any other icons that appear on your thermostat screen, visit our article about what you'll see on your Nest thermostat.

(no circle). To learn about these or any other icons that appear on your thermostat screen, visit our article about what you'll see on your Nest thermostat.

During winter there is no problem, however in summer maybe it needs an extra boost every so often to stop legionnaires? but not sure about every 48 hours? Tried to read through HSE web site, and it does talk about temperatures, however a standard (not Irish) system heat the water at the top, but not bottom of cistern, so there will always be a layer where the water is between 20°C and 50°C and no amount of running boiler or immersion heater will ensure whole tank at over 50°C so unless top of tank always above 50°C then one can never be sure.