I'm currently installing a new kitchen in our house, and have noticed that the existing main stop cock is leaking a little.

The pipe entering the house is blue MDPE and measuring roughly, I assume that it is 32mm (house was built in 1987)

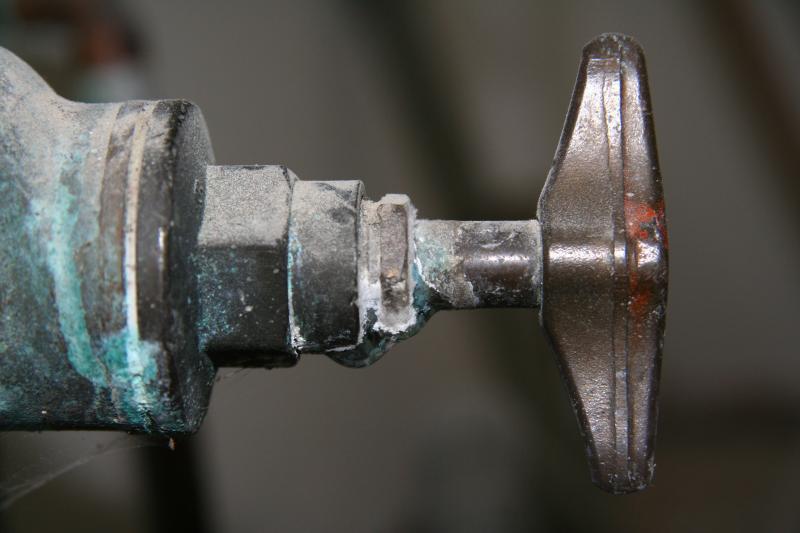

The current stop cock joins directly to the 32mm pipe and then 22mm pipe appears from the other end.

I cant quite work out exactly how the reduction is working becuase there is an earth clamp which I need to remove.

What is the best way of reducing from the 32mm MDPE into the 22mm copper pipe.

I was planning to use a good quality 22mm stop cock and reduce the 32mm pipe down to 22mm using a coupler.

But I can't seem to find exactly what I need - most of the couplers seem to be for joining 2 pieces of MDPE together eg 32mm to 25mm.

Please can anyone help tell me exactly what I need to do this?

Many thanks

Steve

The pipe entering the house is blue MDPE and measuring roughly, I assume that it is 32mm (house was built in 1987)

The current stop cock joins directly to the 32mm pipe and then 22mm pipe appears from the other end.

I cant quite work out exactly how the reduction is working becuase there is an earth clamp which I need to remove.

What is the best way of reducing from the 32mm MDPE into the 22mm copper pipe.

I was planning to use a good quality 22mm stop cock and reduce the 32mm pipe down to 22mm using a coupler.

But I can't seem to find exactly what I need - most of the couplers seem to be for joining 2 pieces of MDPE together eg 32mm to 25mm.

Please can anyone help tell me exactly what I need to do this?

Many thanks

Steve