LAST TIME YOU ARE GETTING TOLD, you MUST clean the small hole underneath the diaphragm, if you dont there is absolutely no point in doing anything, this is a ten minute job from start to finish, best you employ someone that knows what they are doing, there is no magic spray that will sort itI just rang Baxi to ask if the procedure is as follows...

1) connect a tube to the drain off point nipple

2) put the other end of the tube into a bucket

3) open the drain off point valve and wait for the water to go into the bucket until the pressure gauge reads zero or the water stops

4) put rags around the proving pin housing and PCB

5) undo the 6 screws on the proving pin housing

6) carefully open the cover (spring inside)

7) clean the parts with descaler

8) clean the hole the proving pin slides in

9) check the rubber diaphragm (order new one if necessary)

10) reassemble parts

11) tighten up drain off point valve

12) remove tubing

13) repressurise the system

They said they couldn't talk to me as I was not a gas safe engineer.

Is someone able to confirm that the above procedure is correct? I am having a hard time finding a YouTube video showing this. All I seem to find is Combi boiler repairs.

Thanks

Darren

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clean pump proving pin (Baxi System 35/60)

- Thread starter DarrenNewsgroup

- Start date

- Status

- Not open for further replies.

- Joined

- 1 Jan 2021

- Messages

- 19

- Reaction score

- 0

- Country

LAST TIME YOU ARE GETTING TOLD, you MUST clean the small hole underneath the diaphragm, if you dont there is absolutely no point in doing anything, this is a ten minute job from start to finish, best you employ someone that knows what they are doing, there is no magic spray that will sort it

OK I understand, there will be a hole behind the diaphragm, I will clean it. However, you have not confirmed how to ensure all the water is removed from the boiler before I can open the cover with the 6 screws, nor how to fill it back up again. This is what is stopping me from progressing. I don't want to start draining the boiler from the drain off point if there is something I am missing and get gushing water everywhere that I can't stop. I hope you understand my hesitancy. I do appreciate everything that you have told me so far.

Thanks

Darren

It only has 4 screwsbefore I can open the cover with the 6 screws,

- Joined

- 1 Jan 2021

- Messages

- 19

- Reaction score

- 0

- Country

It only has 4 screws

Sorry, yes there are only 4 screws. I was remembering the 6 from the combi YouTube videos I quoted earlier.

stop watching videos of combis , you have a completely different simple setup

- Joined

- 1 Jan 2021

- Messages

- 19

- Reaction score

- 0

- Country

I did stop when you originally pointed out they were combi boilers, I just had it in my head I had 6 screws but I really have 4.

I tried googling "replace system boiler proving pin", "replace system boiler diaphragm", "baxi system boiler". I found this video

. I then came across this video about air in the boiler (time 3:45 into it)

. This might come in handy if I end up with air in it at the end (should I get air in?)

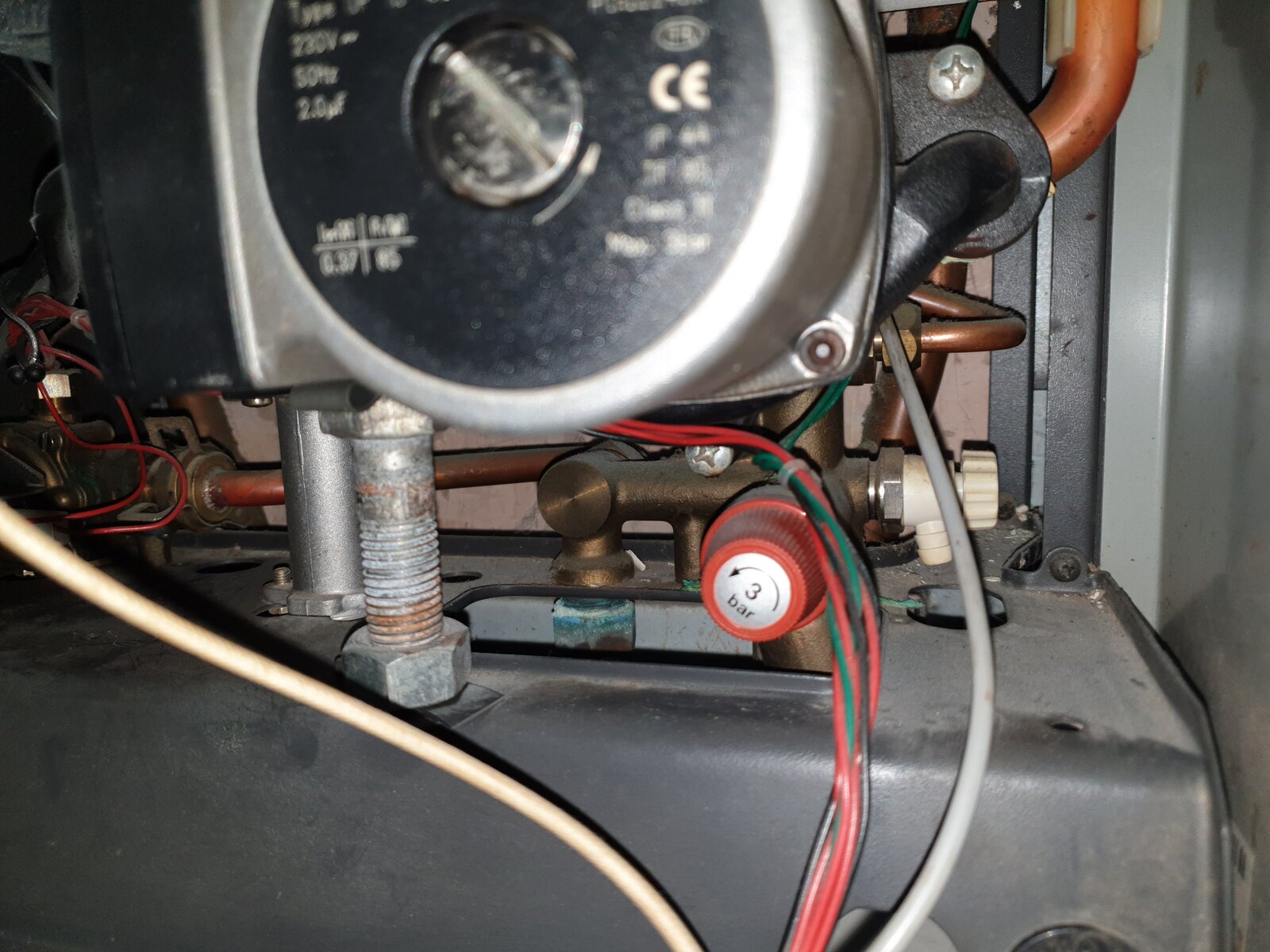

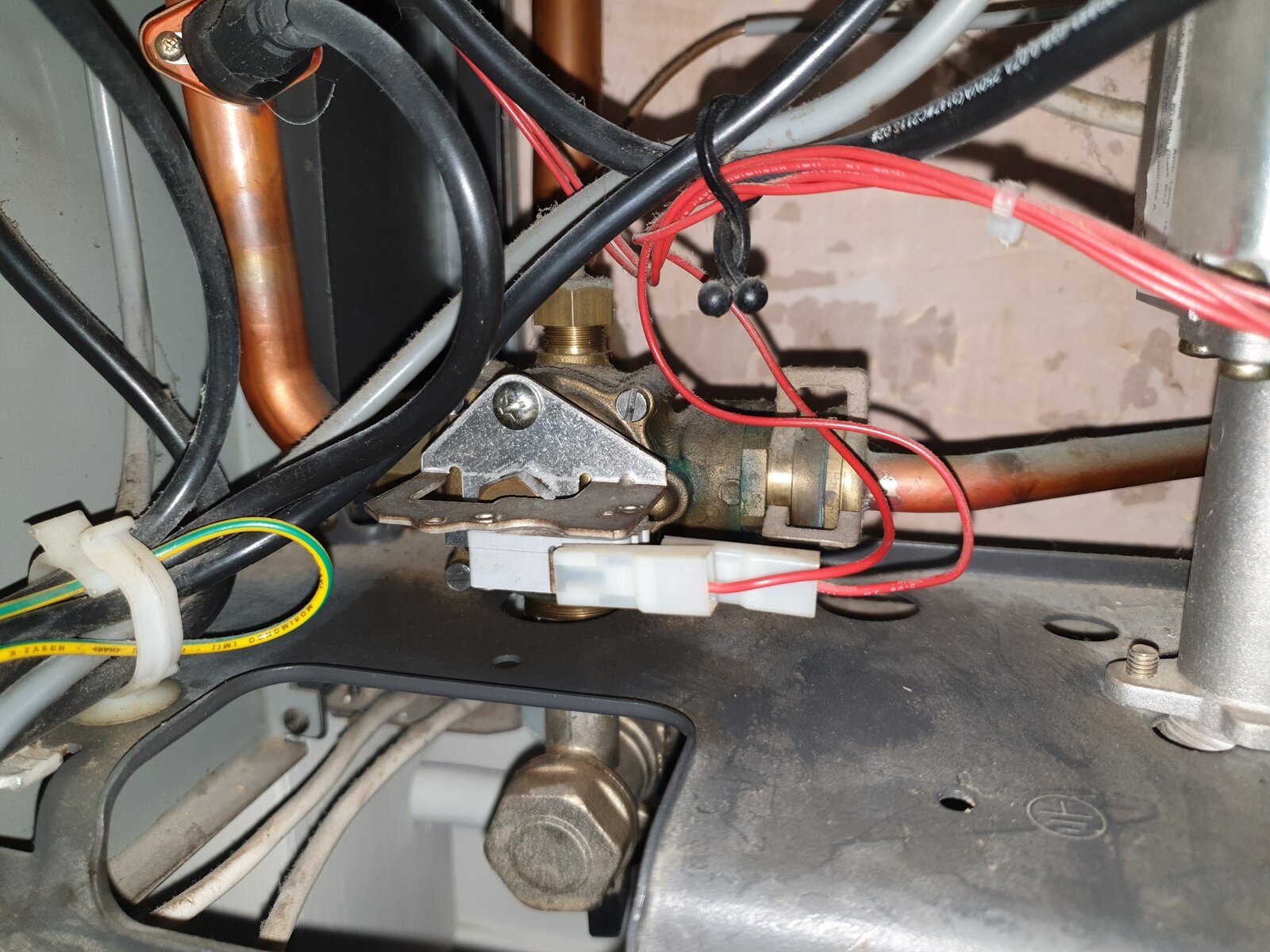

I am attaching photos of my boiler (last one is the back of the unit with the diaphragm). The big bolt on rubber was something I put in to prop up the pump as it was making an annoying humming noise which disappeared if I held the pump).

Can you please explain the sequence required to safely access the diaphragm (and small hole behind it) and reassemble? As far as I can tell the process is now

1) turn off the 2 valves (with the black handles) under the boiler, then connect a tube to the drain off point nipple

2) put the other end of the tube into a bucket

3) open the drain off point valve and wait for the water to go into the bucket until the pressure gauge reads zero or the water stops

4) put rags around the proving pin housing and PCB

5) undo the 4 screws on the proving pin housing

6) carefully open the cover (spring inside)

7) clean the parts with descaler

8) clean the hole the proving pin slides in

9) check the rubber diaphragm (order new one if necessary) and clean the small hole behind the diaphragm

10) reassemble parts

11) close the drain off point valve

12) open the 2 valves under the boiler

13) repressurise the system

14) turn the boiler on, demand some heat, if i hear air in the boiler undo the drain off valve for 30 seconds to let air out (should hear it spluttering with the water?) then tighten the drain off valve

15) remove tubing

16) consider adding more inhibitor (last time was sentinel X100)

Thanks

Darren

I tried googling "replace system boiler proving pin", "replace system boiler diaphragm", "baxi system boiler". I found this video

I am attaching photos of my boiler (last one is the back of the unit with the diaphragm). The big bolt on rubber was something I put in to prop up the pump as it was making an annoying humming noise which disappeared if I held the pump).

Can you please explain the sequence required to safely access the diaphragm (and small hole behind it) and reassemble? As far as I can tell the process is now

1) turn off the 2 valves (with the black handles) under the boiler, then connect a tube to the drain off point nipple

2) put the other end of the tube into a bucket

3) open the drain off point valve and wait for the water to go into the bucket until the pressure gauge reads zero or the water stops

4) put rags around the proving pin housing and PCB

5) undo the 4 screws on the proving pin housing

6) carefully open the cover (spring inside)

7) clean the parts with descaler

8) clean the hole the proving pin slides in

9) check the rubber diaphragm (order new one if necessary) and clean the small hole behind the diaphragm

10) reassemble parts

11) close the drain off point valve

12) open the 2 valves under the boiler

13) repressurise the system

14) turn the boiler on, demand some heat, if i hear air in the boiler undo the drain off valve for 30 seconds to let air out (should hear it spluttering with the water?) then tighten the drain off valve

15) remove tubing

16) consider adding more inhibitor (last time was sentinel X100)

Thanks

Darren

why are you so determined to make a very simple job so complicated ? do not touch the isolating valves or they will leak, just do what everyone has told you it is not hard, you are fixated that your problem has something to do with the pin, it has not , a diaphragm works with different pressures above and below and the orifice that supplies the pressure below the diaphragm is partially blocked or the Diaphragm is worn, sorry for being so hard on you , but this is a weekly chore for most of us, if you dont want to listen to expert advice then do it your own way

- Joined

- 1 Jan 2021

- Messages

- 19

- Reaction score

- 0

- Country

OK, i appreciate your advice and sticking with me here. Please tell me in steps what i need to do. What a trained boiler engineer takes as granted in a few words is sometimes a sequence of steps that are not always obvious. I am being cautious, I can follow instructions if they are laid out clearly.why are you so determined to make a very simple job so complicated ? do not touch the isolating valves or they will leak, just do what everyone has told you it is not hard, you are fixated that your problem has something to do with the pin, it has not , a diaphragm works with different pressures above and below and the orifice that supplies the pressure below the diaphragm is partially blocked or the Diaphragm is worn, sorry for being so hard on you , but this is a weekly chore for most of us, if you dont want to listen to expert advice then do it your own way

Thanks.

Darren

OK last time , drain the boiler and leave the drain tap open, cover the pcb housing with towels or rags, remove the 4 screws, check the Diaphragm, scrub the spindle and clear the small orifice under the diaphragm , rebuild , close drain and re-pressurise the boiler, absolutely nothing difficult about it, if you find that hard get someone in

Has the pump been checked...a weak pump will result in a low differential pressure being applied across the diaphragm.

Should I mention that all the air must be bleed from the radiators and the expansion vessel pressure checked before commencing with the repair...and I'd be replacing that auto air vent too.

You should close down the AAV cap before startng to prevent air ingress...otherwise you'll end up draining the whole boiler which is unnecessary.

Should I mention that all the air must be bleed from the radiators and the expansion vessel pressure checked before commencing with the repair...and I'd be replacing that auto air vent too.

You should close down the AAV cap before startng to prevent air ingress...otherwise you'll end up draining the whole boiler which is unnecessary.

- Joined

- 1 Jan 2021

- Messages

- 19

- Reaction score

- 0

- Country

And there's just what I was saying "drain the boiler" as a single instruction but will take a few steps. How exactly is that done? This is what I had tried searching websites, forums, YouTube and failed to find a step by step answer. Is it just open the drain off valve (with a bucket/hose underneath), or does it involve turning off those 2 valves under the boiler as well, or something else? As Gasguru has just mentioned as well what about the auto air vent and expansion vessel as well? I can see both of those.OK last time , drain the boiler and leave the drain tap open, cover the pcb housing with towels or rags, remove the 4 screws, check the Diaphragm, scrub the spindle and clear the small orifice under the diaphragm , rebuild , close drain and re-pressurise the boiler, absolutely nothing difficult about it, if you find that hard get someone in

Thanks

Darren

- Joined

- 22 Jan 2007

- Messages

- 23,424

- Reaction score

- 3,302

- Country

Is it just open the drain off valve

Yes, but if you are stuck at this blindingly obvious bit you really should get someone in.

- Joined

- 1 Jan 2021

- Messages

- 19

- Reaction score

- 0

- Country

Thank youYes, but if you are stuck at this blindingly obvious bit you really should get someone in.

- Joined

- 1 Jan 2021

- Messages

- 19

- Reaction score

- 0

- Country

With the cold weather yesterday and today our boiler has been on all day so I have not managed to try and fix my problem.

I will report back on my progress when the boiler is not being used.

Darren

I will report back on my progress when the boiler is not being used.

Darren

- Joined

- 1 Jan 2021

- Messages

- 19

- Reaction score

- 0

- Country

I managed to find time to take the cover off the proving pin/diaphragm. I cleaned it up and put it back. The draining process was quite easy in the end. I left the drain off valve open while I loosened the cover and more water came out from the drain off valve so there was very little from removing the cover itself. That was a relief as I didn't want a fish of water near the PCB (which was covered with tags just in case).

Only time will tell if it fixed anything.

Thanks for all your help

Darren

Only time will tell if it fixed anything.

Thanks for all your help

Darren

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 0

- Views

- 2K

- Replies

- 13

- Views

- 3K