- Joined

- 7 Mar 2004

- Messages

- 299

- Reaction score

- 4

- Country

Hi,

I'm having a problem with my plumbing - the builder responsible has long since "departed" and I've only noticed a problem when I've increased the time/duration of my recirculation cycle. It seems that the cold water tap is now producing relatively warm water and I'm concerned that warm water from the return feed is being forced into the cold supply by the pump.

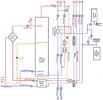

I've attached a diagram (best endeavours, etc.) to show the layout of the system and I suspect it might be down to the position of the check valve being immediately after the pump before it joins the pipe between the hot water return and the cold cylinder inlet if that makes sense? I've also attached a photo of the section that looks wrong to me - any help is appreciated.

Thanks

I'm having a problem with my plumbing - the builder responsible has long since "departed" and I've only noticed a problem when I've increased the time/duration of my recirculation cycle. It seems that the cold water tap is now producing relatively warm water and I'm concerned that warm water from the return feed is being forced into the cold supply by the pump.

I've attached a diagram (best endeavours, etc.) to show the layout of the system and I suspect it might be down to the position of the check valve being immediately after the pump before it joins the pipe between the hot water return and the cold cylinder inlet if that makes sense? I've also attached a photo of the section that looks wrong to me - any help is appreciated.

Thanks