I am in the process of finishing off my house

Renovations.

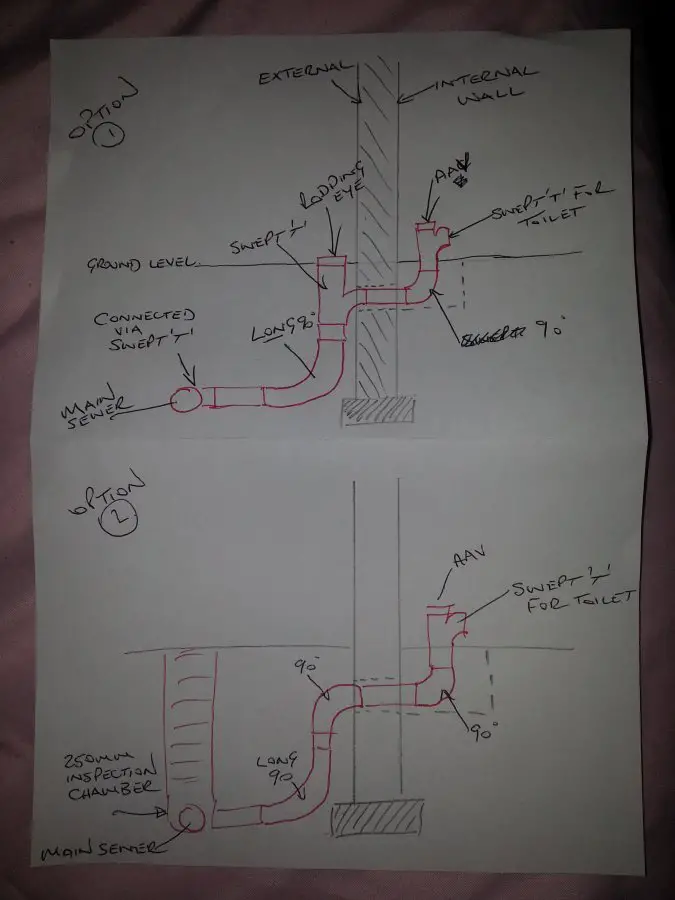

The last job is to connect the downstairs toilet up to the main sewer.

The existing vent stack in to far away to connect upto and i dont really want to erect another

so I think my best options are these

what are your thoughts thanks kris

Renovations.

The last job is to connect the downstairs toilet up to the main sewer.

The existing vent stack in to far away to connect upto and i dont really want to erect another

so I think my best options are these

what are your thoughts thanks kris