Hi all,

House is undergoing major internal strip and rebuild so here's my opportunity to finally get some home automation in. Sparky is the old fashioned sort and although I trust him to do a good and safe job I think I'm going to have to coach him along for this one.

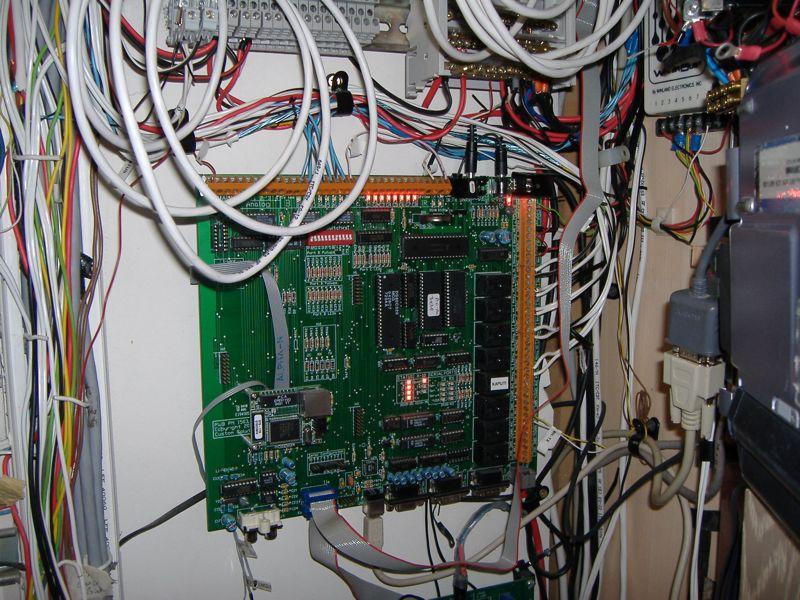

I've come across this: http://www.robot-electronics.co.uk/htm/usb_rly16ltech.htm which is a computer controlled relay board. The board will be conveniently placed next to the consumer unit along with all my other kit.

The challenge: I would like to have every single room light in the house to be switched on/off using both the local room light-switch but would also like the ability to switch on/off using the above computer controlled relay board (I'm a semi-pro software developer so have the know-how to make this happen).

However where I'm totally stumped is on how to wire the lighting to achieve this. I'm thinking it's going to be no different to how one would wire up a double switch to a single light, but then and again, maybe not so....

Anyone experienced in this sort of thing? can you shed any light (pun intended)?

Thanks

House is undergoing major internal strip and rebuild so here's my opportunity to finally get some home automation in. Sparky is the old fashioned sort and although I trust him to do a good and safe job I think I'm going to have to coach him along for this one.

I've come across this: http://www.robot-electronics.co.uk/htm/usb_rly16ltech.htm which is a computer controlled relay board. The board will be conveniently placed next to the consumer unit along with all my other kit.

The challenge: I would like to have every single room light in the house to be switched on/off using both the local room light-switch but would also like the ability to switch on/off using the above computer controlled relay board (I'm a semi-pro software developer so have the know-how to make this happen).

However where I'm totally stumped is on how to wire the lighting to achieve this. I'm thinking it's going to be no different to how one would wire up a double switch to a single light, but then and again, maybe not so....

Anyone experienced in this sort of thing? can you shed any light (pun intended)?

Thanks