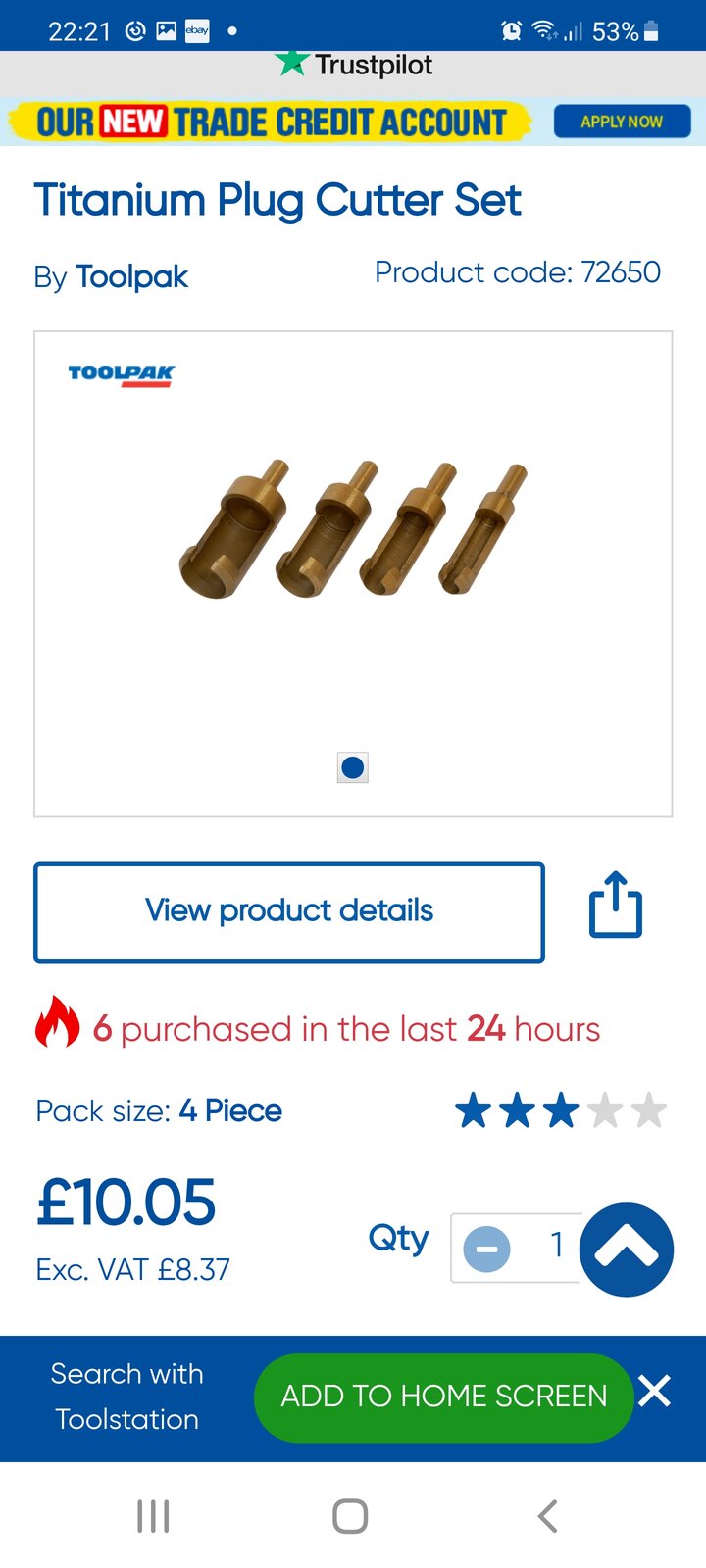

Something like that would do the job, or an Annular Cutter.

Basically cut the plastic out around the screw (like coring an apple).

You could in theory heat some 6mm pipe and push it into the plastic bung, pull it out with the metal screw in the middle.

Get as much remaining plastic out as you can then run a tap through the hole..

Basically cut the plastic out around the screw (like coring an apple).

You could in theory heat some 6mm pipe and push it into the plastic bung, pull it out with the metal screw in the middle.

Get as much remaining plastic out as you can then run a tap through the hole..