Hi,

We need a fire door between our newly insulated/boarded utility room and garage.

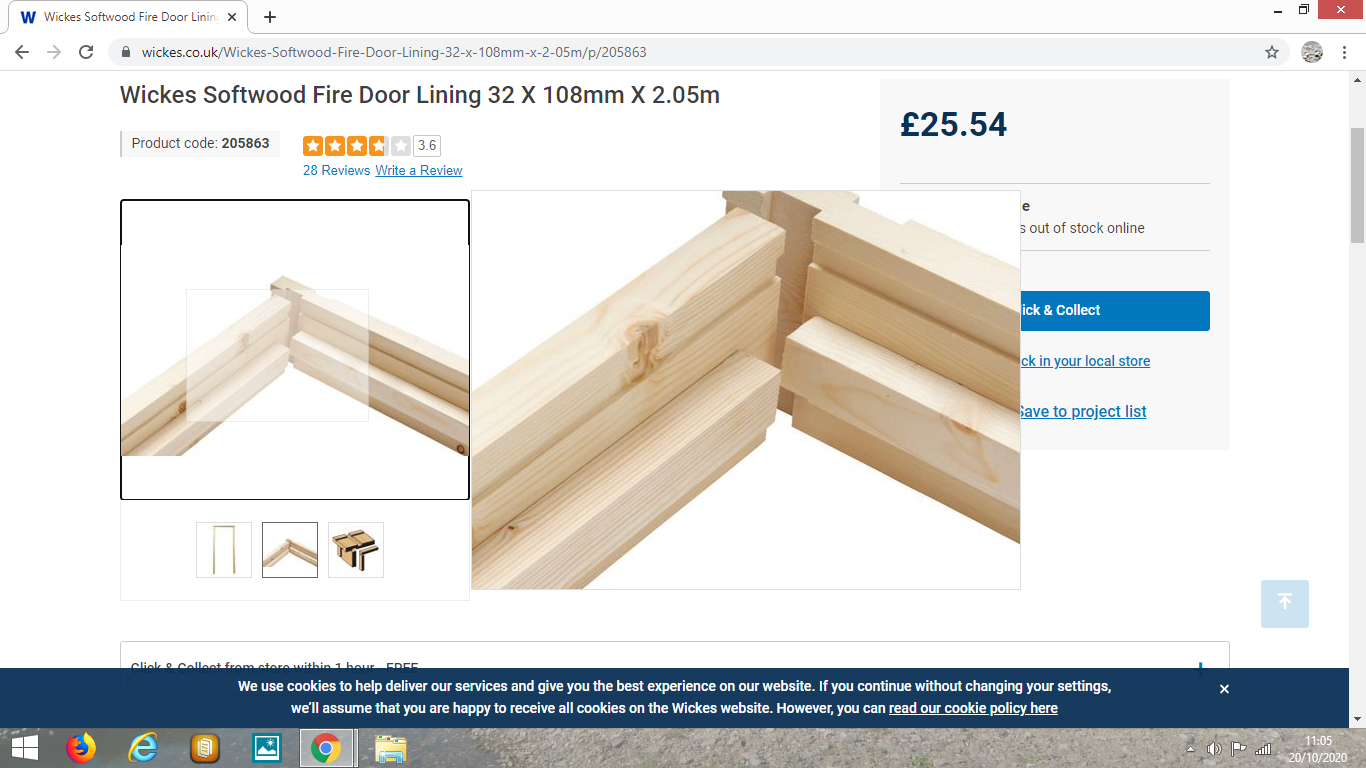

We've got this Wickes fire door frame which is 108 mm deep.

Can someone confirm whether the hinges fix on the edge nearest to the rebate for the intumescent strip, so that the spine of the door sits over the top of the strip when in the closed position? This means 25mm S/S ball bearing hinges overlap onto the groove for the strip, so presumably you have to take the rebate for the hinge down to the depth of the groove for the intumescent strip, which is 4mm.The hinges are 2mm thick.

If the hinges were fixed on the other edge, then the intumescent strip would be on the far side of the door stop, so on the protected room side of the door? Assume that the idea is that the strip expands as possible if there's a fire, ie positioned closer to the fire risk area?

We need a fire door between our newly insulated/boarded utility room and garage.

We've got this Wickes fire door frame which is 108 mm deep.

Can someone confirm whether the hinges fix on the edge nearest to the rebate for the intumescent strip, so that the spine of the door sits over the top of the strip when in the closed position? This means 25mm S/S ball bearing hinges overlap onto the groove for the strip, so presumably you have to take the rebate for the hinge down to the depth of the groove for the intumescent strip, which is 4mm.The hinges are 2mm thick.

If the hinges were fixed on the other edge, then the intumescent strip would be on the far side of the door stop, so on the protected room side of the door? Assume that the idea is that the strip expands as possible if there's a fire, ie positioned closer to the fire risk area?