Hello,

What's the best way of fitting a triple track sliding door to a steel sway frame? I want to minimise thermal bridging.

I'm building my own extension and have Building Control approved plans including those from the Structural Engineer.

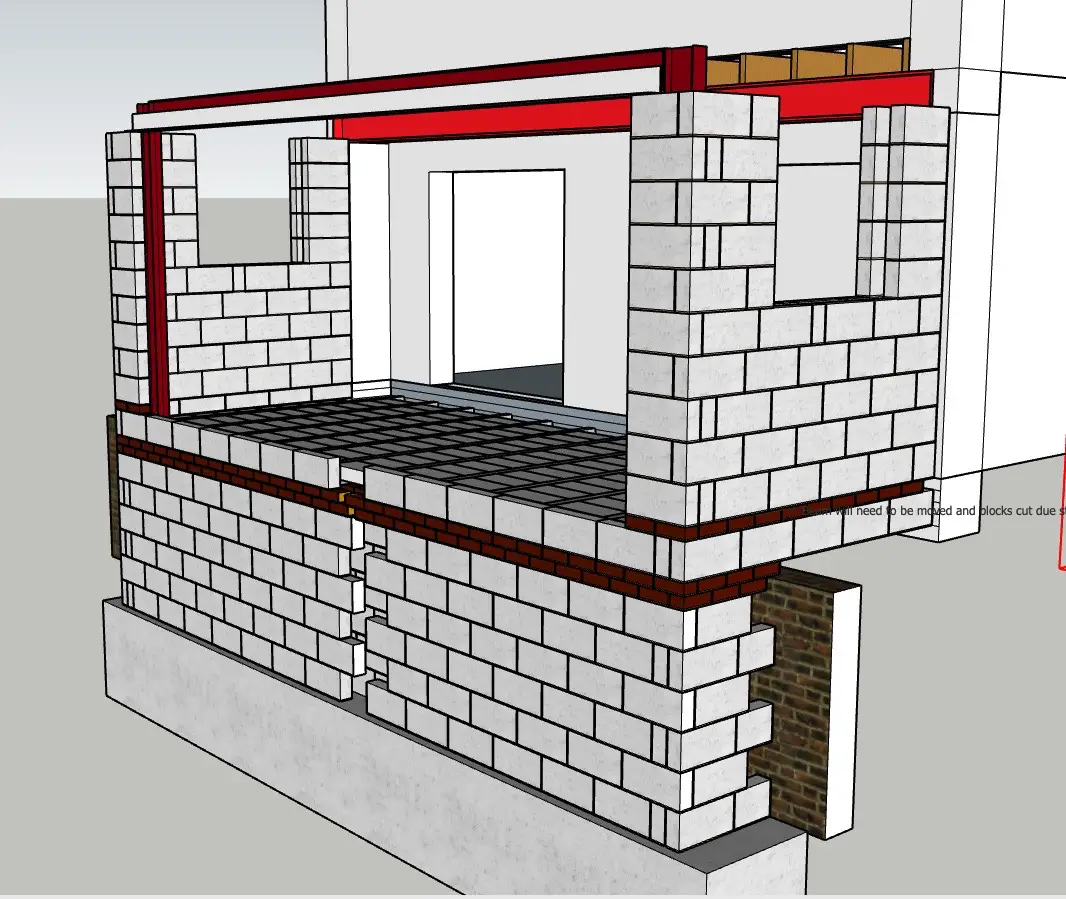

I currently have this:

Designed this:

and I've started "building" in Sketchup:

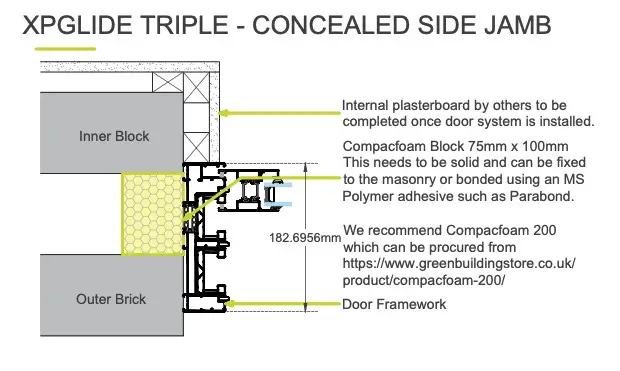

For the jambs the detail they've supplied is this:

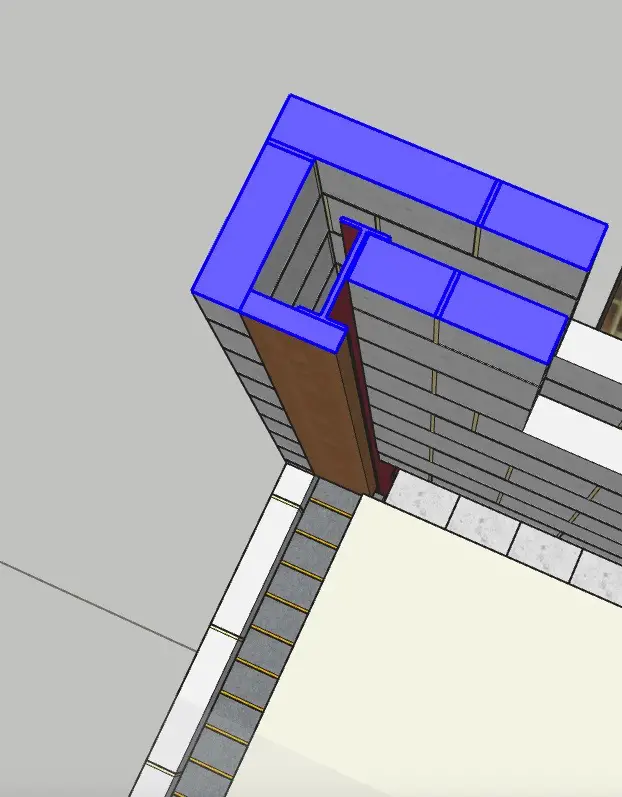

As the triple track is so wide they don't just fix into the outer block. Due to my steel frame I was thinking of just using a 50x200mm timber fixed to the steel to close the cavity with a DPC against the outer block:

Would that work?

Thanks!

What's the best way of fitting a triple track sliding door to a steel sway frame? I want to minimise thermal bridging.

I'm building my own extension and have Building Control approved plans including those from the Structural Engineer.

I currently have this:

Designed this:

and I've started "building" in Sketchup:

For the jambs the detail they've supplied is this:

As the triple track is so wide they don't just fix into the outer block. Due to my steel frame I was thinking of just using a 50x200mm timber fixed to the steel to close the cavity with a DPC against the outer block:

Would that work?

Thanks!