colliefish, Hi

On this board after a couple of days and no reply? WOW

WOW indeed not exactly what I would call a "conventional" design?

1/. Suggestions as follows?

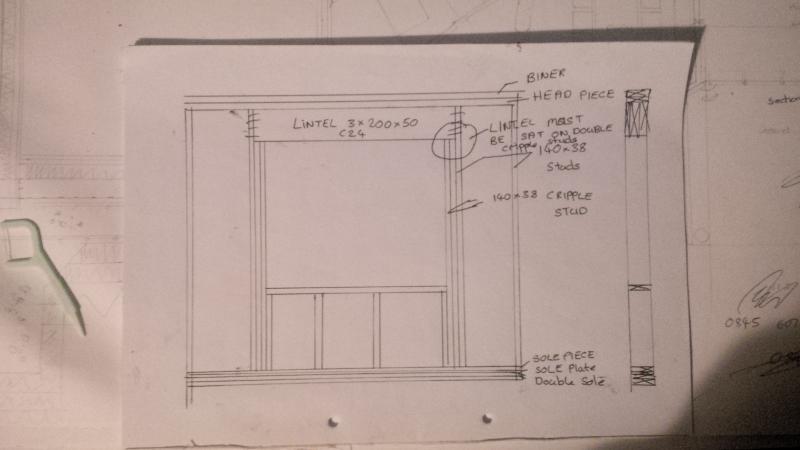

A/. Using galvanized "coach Bolts" you firmly fix the two lintels together, both the outer and inner. If you fit these "Coach Bolts" with the heads into the cavity so that they will not be visible from either the room side or the outside then that should be aesthetically "pleasing" the use of washers under the heads of these devices is advisable.

B/. Should these things not be "designed" by a competent "Engineer"?

C/. Turning now to ensuring these two "independent" "beams" in some way act together? and support each other? And at the same time have an inherent "monocock" function?

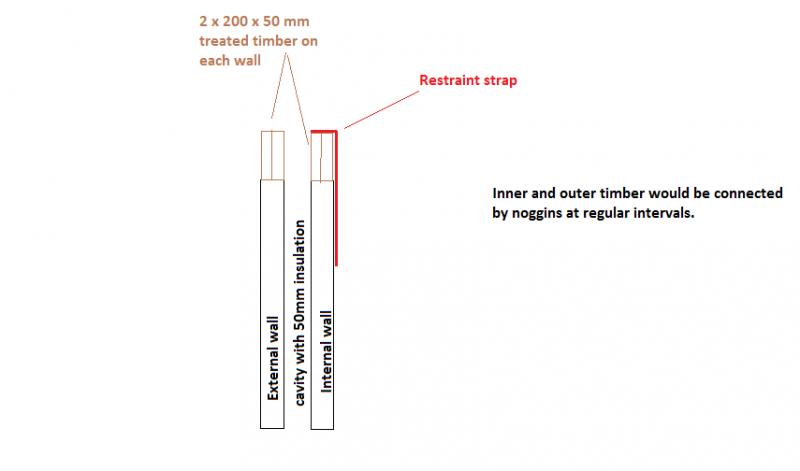

The insertion of noggins between the pair of Lintels would appear "prudent"? Plus at these points it could be thought that some form of firmly fixing the two twin Independent "Lintel units together" is worthy of consideration?

the use again of suitably long "Coach Bolts" on this occasion inserted from the "inside" [plus washers under the heads of the bolts] could form a reasonably "Stable" beam like system?

The bolt heads could be left "proud" of the surface? [dependant on surrounding "finishes"] or recessed and the circular holes filled with "Plugs" of the timber to which it has been fitted?

As for your "Idea" of hold down straps, YES! BUT! ?

How about fitting these straps, not only over the Inner lintel, BUT extending to fit over the pair of twin lintels? the thinking here is that if you follow the above, you are constructing a twinned two part "Beam" "System" comprising of four individual "elements" all firmly tied and bonded one to another?

Following on from the above [If you are still awake ! ! !] if you fix these hold down straps on or as close as you can to the Noggins and coach bolts between the outer and inner lintels the overall tie down and improvement in overall "strength" of the entire design should be improved.

Conversely, "obviously" depending on where you can get a really good solid Hold down fixing could dictate where the hold down straps Et All are fitted?

Hope this has given some Ideas?

Are you surer that you should be asking such questions on this Forum, after all there are very few Structural Engineers in here, just a load of folk with a vast insight to the "build Process" ?

Cheers.

Ken