- Joined

- 8 Aug 2022

- Messages

- 6

- Reaction score

- 0

- Country

Hi DIYnot users,

Was looking for an independent opinion and thought you all might be able to oblige...

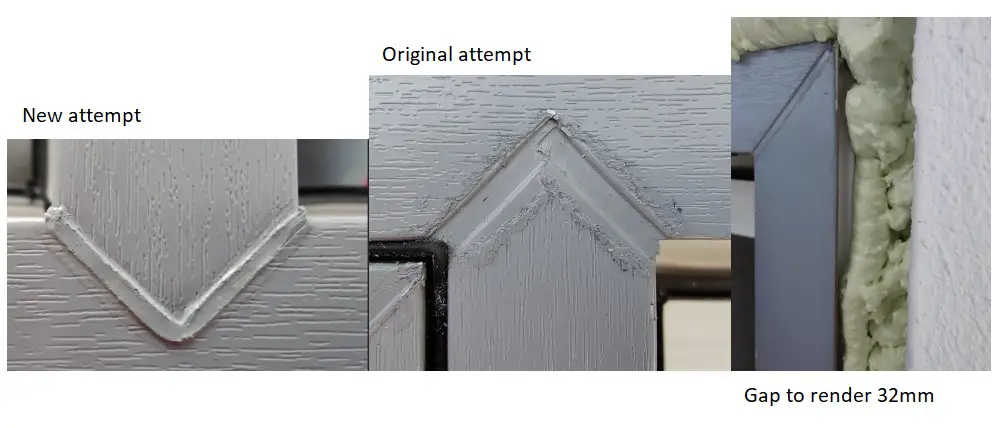

I had some flush fit rehau windows installed with a renolit foil (see middle example)

I told the installer these were junk but he insisted this was industry standard(?)

After much chiding he has come back with an example of his latest attempt(?) - see image on the left

Note: discolouration of foil, uneven line, raised rather than recessed join, lack of sharp angles...

I feel this is also not acceptable and that the welded joints on flush fit windows just don't sit well together and you really need mechanical joints to prevent burning and discolouring the foil (and getting a true line on the joint)

Also the image on the right is an example of a gap between window and render and is approx 32mm and this gap is consistent top and both sides so he is about 64mm out on width and 32mm out on height. What do you think is an acceptable gap for the window and frame to have? Most places I have seen say 1/4" or 3mm.. let me know your thoughts

Sorry for all the questions, opinions appreciated....

Was looking for an independent opinion and thought you all might be able to oblige...

I had some flush fit rehau windows installed with a renolit foil (see middle example)

I told the installer these were junk but he insisted this was industry standard(?)

After much chiding he has come back with an example of his latest attempt(?) - see image on the left

Note: discolouration of foil, uneven line, raised rather than recessed join, lack of sharp angles...

I feel this is also not acceptable and that the welded joints on flush fit windows just don't sit well together and you really need mechanical joints to prevent burning and discolouring the foil (and getting a true line on the joint)

Also the image on the right is an example of a gap between window and render and is approx 32mm and this gap is consistent top and both sides so he is about 64mm out on width and 32mm out on height. What do you think is an acceptable gap for the window and frame to have? Most places I have seen say 1/4" or 3mm.. let me know your thoughts

Sorry for all the questions, opinions appreciated....