Wondering if I can get some advice about a GW 30CXi diverter valve on my brother's boiler which I seem to have become responsible for. It's not a paying job, but if anyone says don't think about tackling this as it's not straightforward, I will leave it as the boiler is in the loft. I don't normally get involved with boiler repairs and I'm not familiar with this model. The hw stopped working after putting the ch on for first time and running the hot tap heats the rads. I took the motor off the Diverter valve and the pin in the valve is able to be pushed in by the motor to the ch position, but is jamming and won't return to the hw position. I managed to get some long nosed, right angle pliers on the pin to give it a pull and hw was restored - but the pin is still stiff.

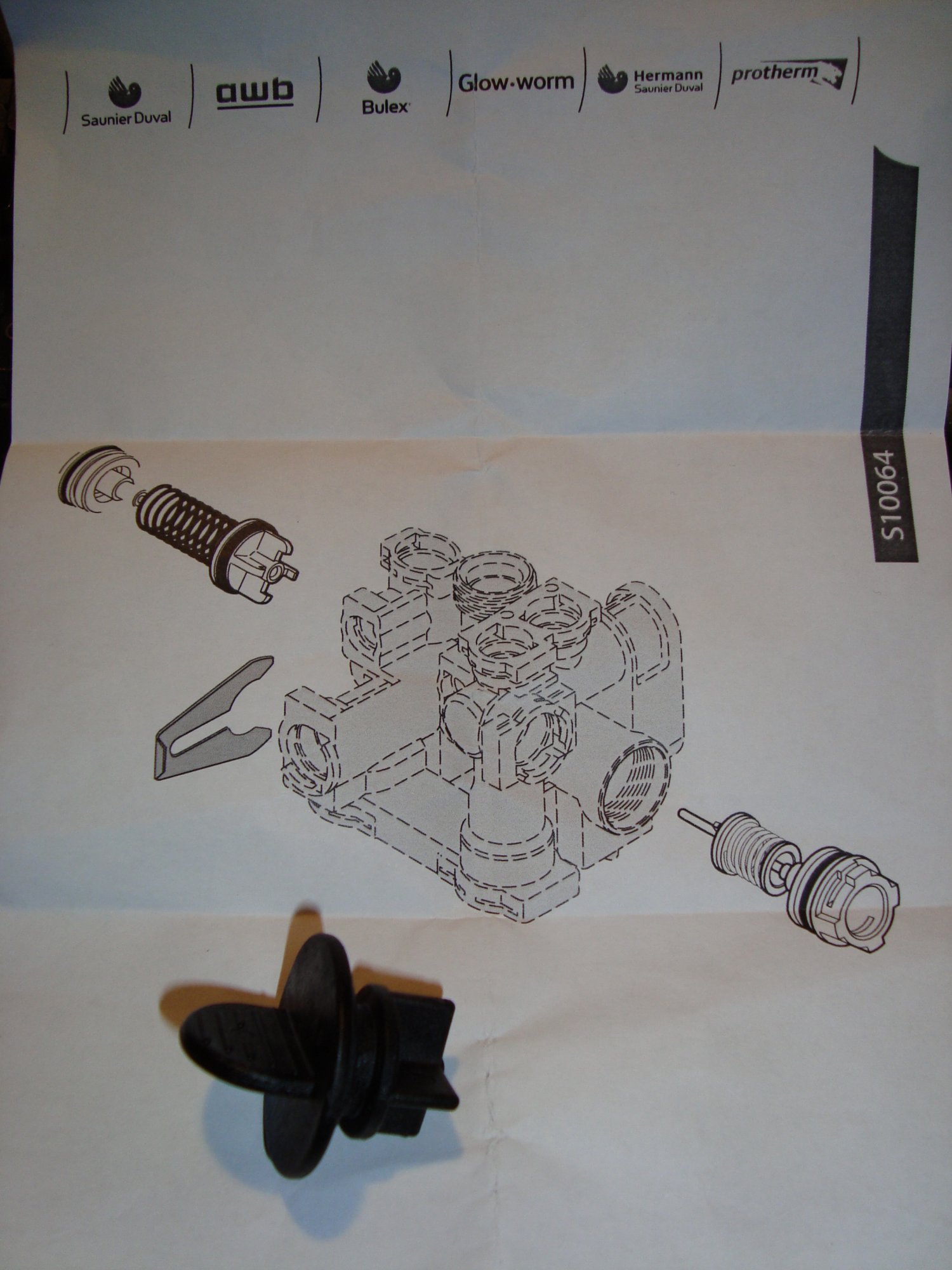

I assume I need a new div. valve cartridge? As it's the pin that's jamming, can I get away with unscrewing the right hand side and removing the pin and fitting a new one? Or do I need to unscrew the bits on the left of the valve too?

Also, are either the right hand side components inc. pin, or even both sides (left and right) replaceable without removing the hydroblock.

Many thanks for any advice about this problem and a solution. I'm keen to repair it without removing any bits that don't need to come out and would prefer not to disturb the hydroblock. I'm aware these things can be leakers!

I assume I need a new div. valve cartridge? As it's the pin that's jamming, can I get away with unscrewing the right hand side and removing the pin and fitting a new one? Or do I need to unscrew the bits on the left of the valve too?

Also, are either the right hand side components inc. pin, or even both sides (left and right) replaceable without removing the hydroblock.

Many thanks for any advice about this problem and a solution. I'm keen to repair it without removing any bits that don't need to come out and would prefer not to disturb the hydroblock. I'm aware these things can be leakers!

Last edited: