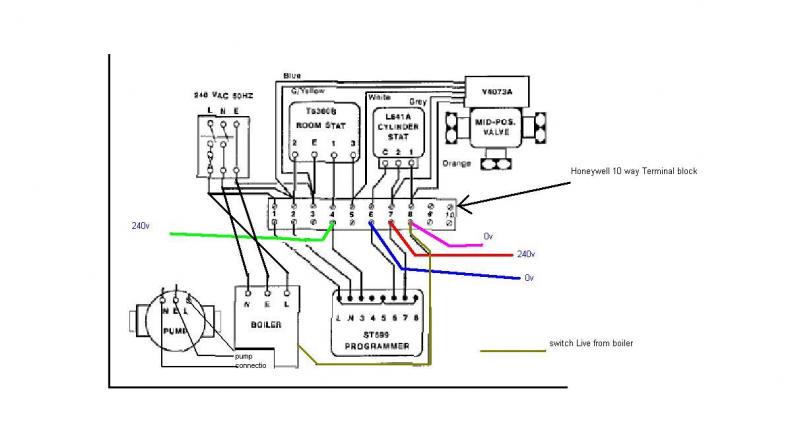

I have been following the Honeywell Y plan diagram to connect my system and it doesn’t seem to work properly. On the programmer (ST699) I slide the Hot water only button to cont. (continuous) nothing happens, boiler doesn’t fire up. Only when I turn the room thermostat the boiler will fire up and even if I slide the Hot water to off position the boiler is still working, to switch it off I need to turn the room stat to minimum position.

I have not tested Central Heating system as I found problem with the Hot water and didn’t want to cause any damage. So I need to isolate this problem before I move on I would really appreciate any help, and would love to know how to test with a voltmeter the cylinder stat, room stat so i can illuminate these from being faulty and what readings i should be getting across programmer terminal block and Honeywell 10 way block

I would really appreciate any help, and would love to know how to test with a voltmeter the cylinder stat, room stat so i can illuminate these from being faulty and what readings i should be getting across programmer terminal block and Honeywell 10 way block

Information of Hardware:

Boiler Glow-worm Ultimate 50FF

Cylinder Stat (no manufacturing marking),

Room Stat (no manufacturing marking), very old dial version, and 4 wires connection

Honeywell mid-position valve – v4073

Honeywell Programmer ST699

Honeywell 10 way terminal block

Wiring configuration:

Boiler

From the boiler L, N, E connected to 10 way Honeywell terminal block,

Boiler Live = Connects to Honeywell terminal block 8,

Boiler Neutral =Connects to Honeywell terminal block 2,

Boiler Earth= Connects to Honeywell terminal block 3.

Note: I have a one link across SL and 9 and second link across K1 and K2

Pump

From the pump the 3 wires L, N, E are connected as follow:

Pump Live = Connects to Honeywell terminal block 8{same as boiler live}

Pump Neutral = Connects to Honeywell terminal block 2 {same as boiler neutral}

Pump Earth = Connects to Honeywell terminal block 3 {same as boiler earth}

Programmer ST699

*Inside the programmer I got links across terminal 1-5-8

Programmer terminal L* is connected to Honeywell terminal block 1

Programmer terminal N is connected to Honeywell terminal block 2

Programmer terminal 3 is connected to Honeywell terminal block 4

Programmer terminal 4 not connected

Programmer terminal 5* Links to 1 and 8 inside the programmer terminal

Programmer terminal 6 is connected to Honeywell terminal block 6

Programmer terminal 7 is connected to Honeywell terminal block 7

Programmer terminal 8* Links to 1 and 5 insider the programmer terminal

Honeywell terminal block 10 Way:

Terminal 1 is connected to Live Load on FCU (Spur)

Terminal 2 is connected to Neutral on FCU (spur) + Room Stat blue wire + Mid-Position valve blue wire.

Terminal 3 is connected to Earth on FCU (spur) + Room Stat G/Yellow wire + Mid –Position valve G/yellow

Terminal 4 is connected to Programmer ST699 terminal 3 and Room stat (1) Red wire

Terminal 5 is connected to room stat (3) Yellow wire and also mid-position valve white wire.

Terminal 6 is connected to Programmer ST699 terminal 6 and Cylinder stat (Common) brown wire

Terminal 7 is connected to Programmer ST699 terminal 7 and Cylinder stat (2) G/Yellow wire and mid-position valve Grey wire

Terminal 8 is connected to Boiler Live(which goes back downstairs to the boiler terminal control box marked L) + Pump Live and Cylinder stat (1) Blue wire and mid-position valve Orange wire.

Terminal 9 is Not used

Terminal 10 is Not used

What I found conflicting and really confusing some Y-plan diagrams I read show that the pump Live goes back to the boiler marking P terminal in its control box( someting about over run was mentioned). And boiler has a permanent live feed to L. The SL is connected to mid-position valve orange wire and to cylinder stat terminal (1). Is this method correct?

off question, just for my reference, How do I find out what type of system is installed i.e. A gravity domestic hot water and pumped central heating system or a Fully pumped open vented system. How does one distinguish this. This is what i have fitted :

I have a tank in my loft and the pipes come down to my airing cupboard in the bath room where the cylinder, pump, mid-position valve, programmer ST699 and Honeywell terminal box is fitted and the boiler is fitted downstairs in the kitchen.

Thanks in advance

I have not tested Central Heating system as I found problem with the Hot water and didn’t want to cause any damage. So I need to isolate this problem before I move on

Information of Hardware:

Boiler Glow-worm Ultimate 50FF

Cylinder Stat (no manufacturing marking),

Room Stat (no manufacturing marking), very old dial version, and 4 wires connection

Honeywell mid-position valve – v4073

Honeywell Programmer ST699

Honeywell 10 way terminal block

Wiring configuration:

Boiler

From the boiler L, N, E connected to 10 way Honeywell terminal block,

Boiler Live = Connects to Honeywell terminal block 8,

Boiler Neutral =Connects to Honeywell terminal block 2,

Boiler Earth= Connects to Honeywell terminal block 3.

Note: I have a one link across SL and 9 and second link across K1 and K2

Pump

From the pump the 3 wires L, N, E are connected as follow:

Pump Live = Connects to Honeywell terminal block 8{same as boiler live}

Pump Neutral = Connects to Honeywell terminal block 2 {same as boiler neutral}

Pump Earth = Connects to Honeywell terminal block 3 {same as boiler earth}

Programmer ST699

*Inside the programmer I got links across terminal 1-5-8

Programmer terminal L* is connected to Honeywell terminal block 1

Programmer terminal N is connected to Honeywell terminal block 2

Programmer terminal 3 is connected to Honeywell terminal block 4

Programmer terminal 4 not connected

Programmer terminal 5* Links to 1 and 8 inside the programmer terminal

Programmer terminal 6 is connected to Honeywell terminal block 6

Programmer terminal 7 is connected to Honeywell terminal block 7

Programmer terminal 8* Links to 1 and 5 insider the programmer terminal

Honeywell terminal block 10 Way:

Terminal 1 is connected to Live Load on FCU (Spur)

Terminal 2 is connected to Neutral on FCU (spur) + Room Stat blue wire + Mid-Position valve blue wire.

Terminal 3 is connected to Earth on FCU (spur) + Room Stat G/Yellow wire + Mid –Position valve G/yellow

Terminal 4 is connected to Programmer ST699 terminal 3 and Room stat (1) Red wire

Terminal 5 is connected to room stat (3) Yellow wire and also mid-position valve white wire.

Terminal 6 is connected to Programmer ST699 terminal 6 and Cylinder stat (Common) brown wire

Terminal 7 is connected to Programmer ST699 terminal 7 and Cylinder stat (2) G/Yellow wire and mid-position valve Grey wire

Terminal 8 is connected to Boiler Live(which goes back downstairs to the boiler terminal control box marked L) + Pump Live and Cylinder stat (1) Blue wire and mid-position valve Orange wire.

Terminal 9 is Not used

Terminal 10 is Not used

What I found conflicting and really confusing some Y-plan diagrams I read show that the pump Live goes back to the boiler marking P terminal in its control box( someting about over run was mentioned). And boiler has a permanent live feed to L. The SL is connected to mid-position valve orange wire and to cylinder stat terminal (1). Is this method correct?

off question, just for my reference, How do I find out what type of system is installed i.e. A gravity domestic hot water and pumped central heating system or a Fully pumped open vented system. How does one distinguish this. This is what i have fitted :

I have a tank in my loft and the pipes come down to my airing cupboard in the bath room where the cylinder, pump, mid-position valve, programmer ST699 and Honeywell terminal box is fitted and the boiler is fitted downstairs in the kitchen.

Thanks in advance