Hi Folks,

Apologies, long post, in an attempt to provide as much information as possible up front.

I recently moved house and have inherited a heating system which appears to have been reasonably well installed (by British Gas), but has suffered, maintenance wise in the last few years.

EDIT TO ADD: House is old (18th C 9" solid N-facing front wall, 1950s (cavity) everywhere else), with insulation crying out to be upgrades.

EDIT AGAIN TO ADD: Boiler is a BG 330+ set at 28Kw (Believe this is a rebadged GlowWorm Flexicom HX with a posh display).

We had the boiler serviced prior to moving in (a family member was present, I was not), and through the winter I have performed a few 'remedial' tasks (e.g. replacing broken Zone valve, repeated cleaning of magnaclean to try to degunge system somewhat, and replacement of Kitchen radiator) to keep it ticking over / us warm until I can get the time to drain down, and treat with chemicals, etc to 'clean it up' properly (to be honest, rads are old inefficient sort, so may swap them all out in one go at that time).

The most recent remedial task necessary was this past weekend. Replacing the BG Multihead G pump (with a Grundfos UPS2), as had noticed the old pump was incredibly noisy, and only really worked on highest setting, and was not always starting when receiving power (causing boiler to enter into a 'dry' fail mode, requiring reset). Removal of pump head showed the expected rust & gunge build up.

UPS2 is now fitted, incredibly quiet in comparison, and has had a number of knock-on effects to the rest of the system, as follows:

* Boiler 'approach to heating water' appears to have changed, with longer periods of it running 'flat out' before stepping down to 1/3-1/2 power to maintain temperature.

* Radiators all generally hotter, esp. those at end of circuit which had been difficult to get hot previously.

* Noticing a significant increase in noise from the TacoSetter set as bypass for the system (i.e. when both valves closed in overrun).

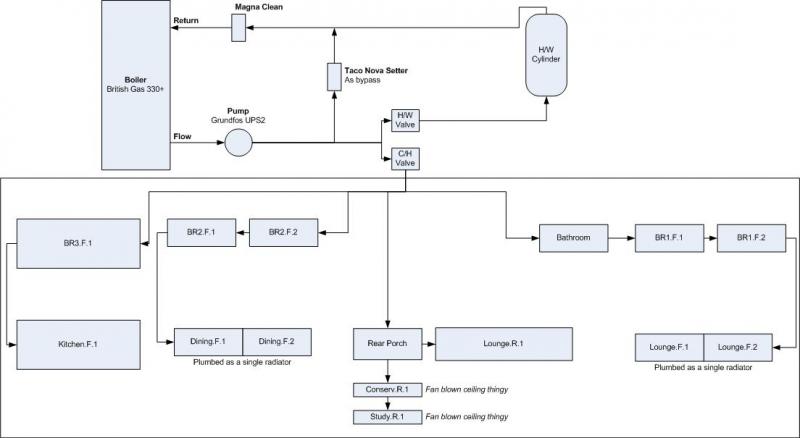

Here's a diagram of what the system layout looks like:

(I failed to include a return from the radiators, but it comes up from the floor before being joined by H/W return, TacoSetter return and before flowing into the MagnaClean)

And so, finally, to questions:

1] Any advice on correct pump setting for the system I have? Or trial-and-error approach? Doesn't seem to syphon or pump out anything into/from header tank on any setting.

2] It would appear I will need to go through the process of balancing the radiators again - correct?

2a] Assuming yes, aiming for 12ish degree drop across each rad?

2b] What overall drop should I expect across the boiler flow/return?

2c] If drop across the boiler flow/return is smaller than target, do I reduce pump speed and start the balancing process again?

3] Noise from the TacoSetter is presumably due to increased flow through it when it overrun (new pump dishing out a lot more power than old).

3a] Adjustment of TacoSetter presumably needs to be a part of the balancing process? It has letters A through G repeated around the screw, do these serve any useful purpose in the setting process? Or is it simply a gate valve with a flow rate meter built in?

3b] the flow-rate meter on the TacoSetter is rather 'gunged up', what should I be expecting to see in there behind all the gunge? Or is this an indication I should ignore the reading.

3c] What kind of flow-rate should I be expecting to set here when in overrun mode?

Many, many thanks in advance for taking the time to look and respond.

Regards,

Gavin.

Apologies, long post, in an attempt to provide as much information as possible up front.

I recently moved house and have inherited a heating system which appears to have been reasonably well installed (by British Gas), but has suffered, maintenance wise in the last few years.

EDIT TO ADD: House is old (18th C 9" solid N-facing front wall, 1950s (cavity) everywhere else), with insulation crying out to be upgrades.

EDIT AGAIN TO ADD: Boiler is a BG 330+ set at 28Kw (Believe this is a rebadged GlowWorm Flexicom HX with a posh display).

We had the boiler serviced prior to moving in (a family member was present, I was not), and through the winter I have performed a few 'remedial' tasks (e.g. replacing broken Zone valve, repeated cleaning of magnaclean to try to degunge system somewhat, and replacement of Kitchen radiator) to keep it ticking over / us warm until I can get the time to drain down, and treat with chemicals, etc to 'clean it up' properly (to be honest, rads are old inefficient sort, so may swap them all out in one go at that time).

The most recent remedial task necessary was this past weekend. Replacing the BG Multihead G pump (with a Grundfos UPS2), as had noticed the old pump was incredibly noisy, and only really worked on highest setting, and was not always starting when receiving power (causing boiler to enter into a 'dry' fail mode, requiring reset). Removal of pump head showed the expected rust & gunge build up.

UPS2 is now fitted, incredibly quiet in comparison, and has had a number of knock-on effects to the rest of the system, as follows:

* Boiler 'approach to heating water' appears to have changed, with longer periods of it running 'flat out' before stepping down to 1/3-1/2 power to maintain temperature.

* Radiators all generally hotter, esp. those at end of circuit which had been difficult to get hot previously.

* Noticing a significant increase in noise from the TacoSetter set as bypass for the system (i.e. when both valves closed in overrun).

Here's a diagram of what the system layout looks like:

(I failed to include a return from the radiators, but it comes up from the floor before being joined by H/W return, TacoSetter return and before flowing into the MagnaClean)

And so, finally, to questions:

1] Any advice on correct pump setting for the system I have? Or trial-and-error approach? Doesn't seem to syphon or pump out anything into/from header tank on any setting.

2] It would appear I will need to go through the process of balancing the radiators again - correct?

2a] Assuming yes, aiming for 12ish degree drop across each rad?

2b] What overall drop should I expect across the boiler flow/return?

2c] If drop across the boiler flow/return is smaller than target, do I reduce pump speed and start the balancing process again?

3] Noise from the TacoSetter is presumably due to increased flow through it when it overrun (new pump dishing out a lot more power than old).

3a] Adjustment of TacoSetter presumably needs to be a part of the balancing process? It has letters A through G repeated around the screw, do these serve any useful purpose in the setting process? Or is it simply a gate valve with a flow rate meter built in?

3b] the flow-rate meter on the TacoSetter is rather 'gunged up', what should I be expecting to see in there behind all the gunge? Or is this an indication I should ignore the reading.

3c] What kind of flow-rate should I be expecting to set here when in overrun mode?

Many, many thanks in advance for taking the time to look and respond.

Regards,

Gavin.