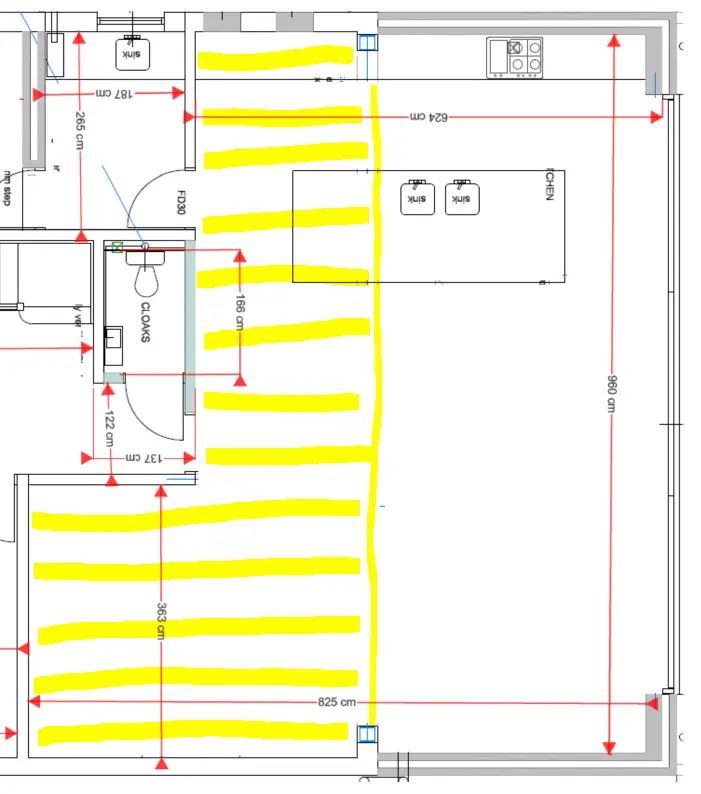

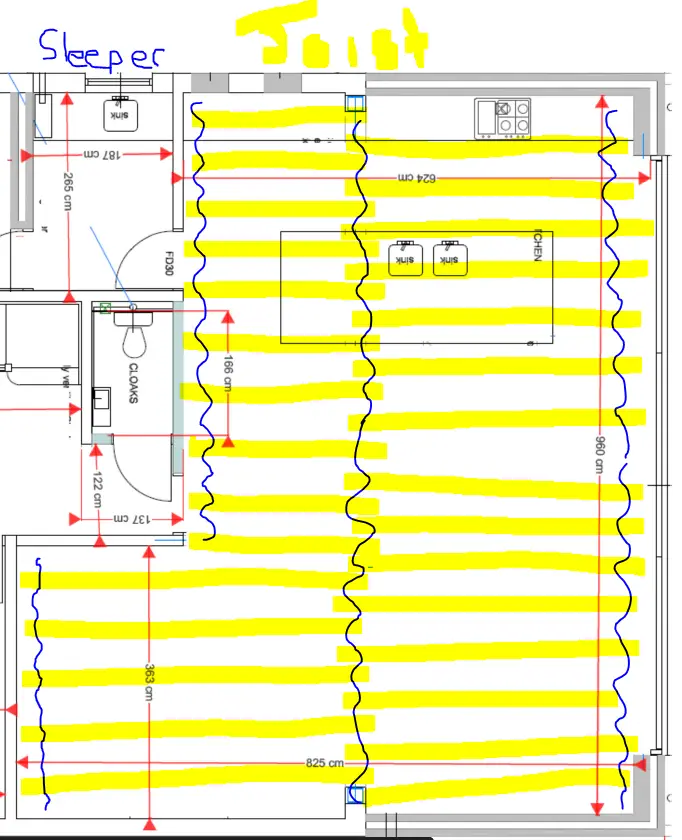

Hi i have an existing suspended timber floor to 2 rooms that are being opened up into a new extension (as below). The existing timbers are 4x2 sat on sleeper walls at each end and are decent but slightly twisted after 100 years. They have a 300mm ventilation void between the ground and the underside of the joist.

The extension is being constructed with a suspended timber floor which the SE has spec'd in 8x2's @ 400c. At the same levels this gives a 200mm ventilation void which I understand is in line with BC requirements.

I need to remove 40% of the joists to install a pad foundation for teh steel columns so is it best to bite the bullet and just remove the existing joists and sleeper walls and rebuild it all in 8x2's breaking the spans into 2 4m areas as below? If so are sleeper walls the best method or wall plates and hangers with a sleeper in the middle?

Thanks in advance for the help.

The extension is being constructed with a suspended timber floor which the SE has spec'd in 8x2's @ 400c. At the same levels this gives a 200mm ventilation void which I understand is in line with BC requirements.

I need to remove 40% of the joists to install a pad foundation for teh steel columns so is it best to bite the bullet and just remove the existing joists and sleeper walls and rebuild it all in 8x2's breaking the spans into 2 4m areas as below? If so are sleeper walls the best method or wall plates and hangers with a sleeper in the middle?

Thanks in advance for the help.