- Joined

- 10 Apr 2016

- Messages

- 110

- Reaction score

- 5

- Country

Hi,

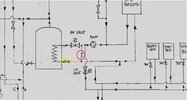

My S-plan has a by-pass valve (common plegler gate valve) that seems incapable of closing the flow (see red circle of the diagram).

I tried to close it completely, turning until the end but the output pipe did not get colder, at touch seems the same temp as the input.

I suspect some crap was deposited in the bottom?

How can I tell whether it's actually closing properly??

Replacing it is a one-day job because it's very fiddly because it's behind the hot water cylinder, so would like to avoid it.

I wanted to replace it with a ball valve so I can tell for sure when it's fully open or partially closed.

I want to make sure that the by-pass pipe does not get too much flow and the hot water cylinder gets its fair amount.

I suspect too much water flowing in the bypass because the how water cylinder takes a lot of time to heat up.

Any suggestion whether I should replace the valve or some way to confirm that the valve is actually working and I can use it to balance the by-pass circuit?

Many Thanks

My S-plan has a by-pass valve (common plegler gate valve) that seems incapable of closing the flow (see red circle of the diagram).

I tried to close it completely, turning until the end but the output pipe did not get colder, at touch seems the same temp as the input.

I suspect some crap was deposited in the bottom?

How can I tell whether it's actually closing properly??

Replacing it is a one-day job because it's very fiddly because it's behind the hot water cylinder, so would like to avoid it.

I wanted to replace it with a ball valve so I can tell for sure when it's fully open or partially closed.

I want to make sure that the by-pass pipe does not get too much flow and the hot water cylinder gets its fair amount.

I suspect too much water flowing in the bypass because the how water cylinder takes a lot of time to heat up.

Any suggestion whether I should replace the valve or some way to confirm that the valve is actually working and I can use it to balance the by-pass circuit?

Many Thanks