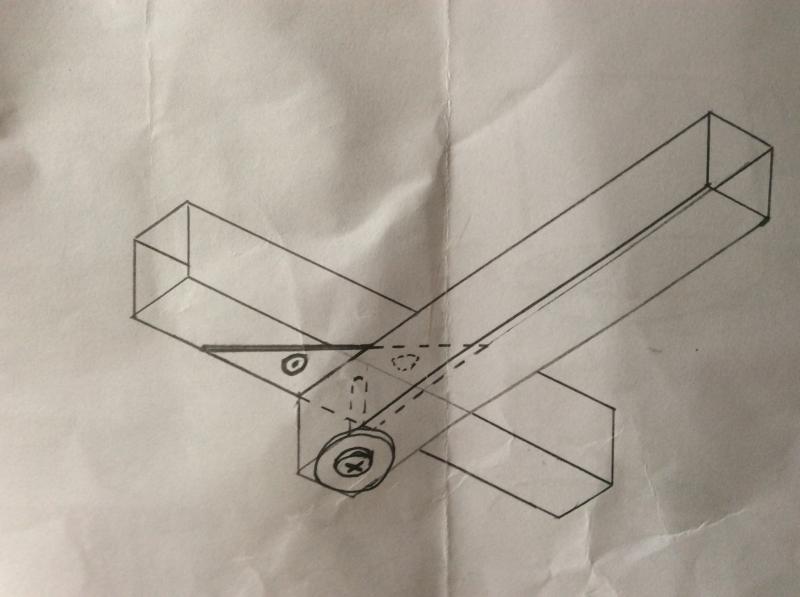

Hi, I've made a T-joint recently between two sections of aluminium box section and I rivited a sheet aluminium triangle between them to try and prevent rotation, with two rivets in each corner, and a machine screw actualy through the two aluminium box sections. While this did a good job at preventing large rotation, there is still some movement in the joint. I've figured that this is because the screw is slightly smaller than the hole and so the joint is rotating about the two rivets. So does anybody know of a decent way to reduce wobble in a loose screw, one which is a bit too small for the hole? So far all I've though of is wrapping some tape arround the screw, which doesn't sound perticularly durable.

Thanks.

Thanks.