Hi,

I've been looking for some info on how to correctly read pump graphs. Information seems to be a bit difficult to find.

Anybody with knowhow can give me some details how to read the following chart?

(Pump is fixed on stage 1 by setting d19)

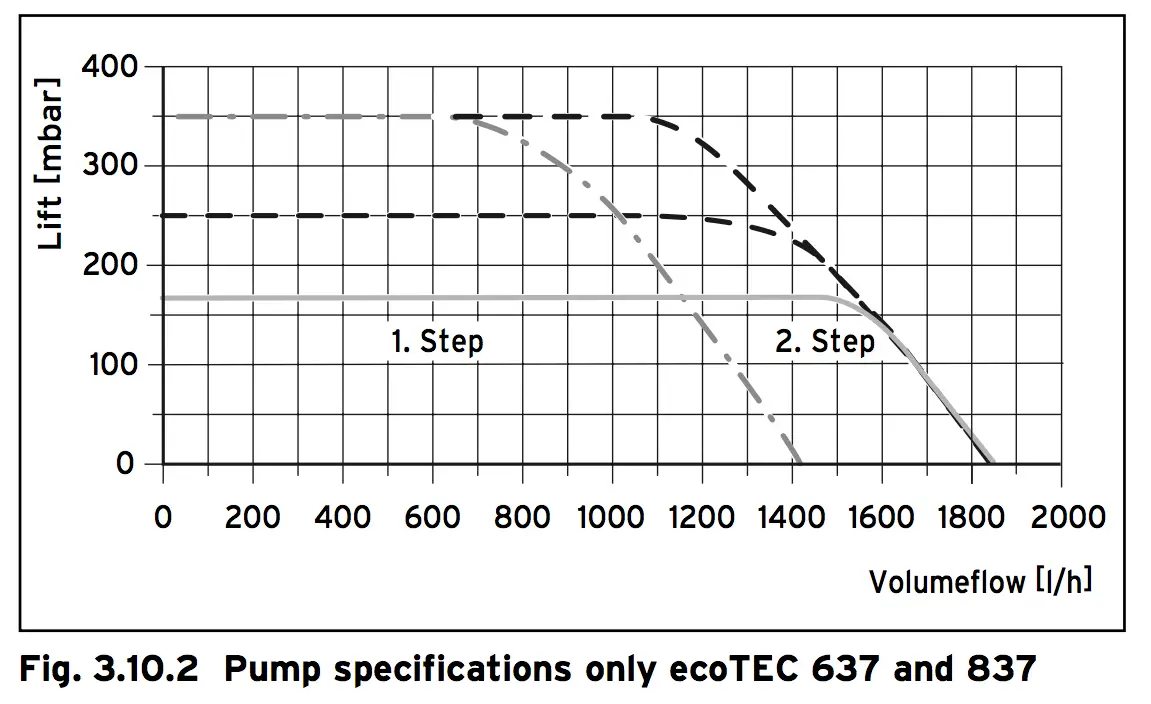

The residual pump discharge height depending on the by-pass valve is shown in Fig. 3.10.1 (ecoTEC plus) and 3.10.2 (ecoTEC plus 637 / 837).

When running at 20 kW (Max, set on d0) the difference between flow and return is reported (d40/41) as 14 degrees. This translates to roughly 1220 litres of water heated (by 14 degrees) per hour. Correct?

So this is what the pump pushes around. Now how to interpret the graph.

Am I correct is saying that in that case the resistance of the system is around 150 mbar, or 1.5 meter of head?

I've been looking for some info on how to correctly read pump graphs. Information seems to be a bit difficult to find.

Anybody with knowhow can give me some details how to read the following chart?

(Pump is fixed on stage 1 by setting d19)

The residual pump discharge height depending on the by-pass valve is shown in Fig. 3.10.1 (ecoTEC plus) and 3.10.2 (ecoTEC plus 637 / 837).

When running at 20 kW (Max, set on d0) the difference between flow and return is reported (d40/41) as 14 degrees. This translates to roughly 1220 litres of water heated (by 14 degrees) per hour. Correct?

So this is what the pump pushes around. Now how to interpret the graph.

Am I correct is saying that in that case the resistance of the system is around 150 mbar, or 1.5 meter of head?