Hi,

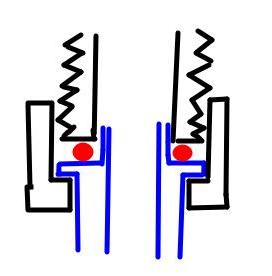

I had to unscrew this plastic fitting which is part of an existing water softener install. Now it leaks when tightened and I think its because I am not tightening it properly. Its a strange fitting as it has the rubber washer half way up the thread. Can someone please explain how this type of fitting should be tightened?

Cheers

I had to unscrew this plastic fitting which is part of an existing water softener install. Now it leaks when tightened and I think its because I am not tightening it properly. Its a strange fitting as it has the rubber washer half way up the thread. Can someone please explain how this type of fitting should be tightened?

Cheers