I have a few questions about how structural beams are connected for a project I'm doing. I have all the structural calculations, padstones, joints from a SE, I'm not putting the beams in myself - this is quite probably obvious to any decent builder, I'm just interested to understand - not least that I may perhaps be able to sensibly select a builder!

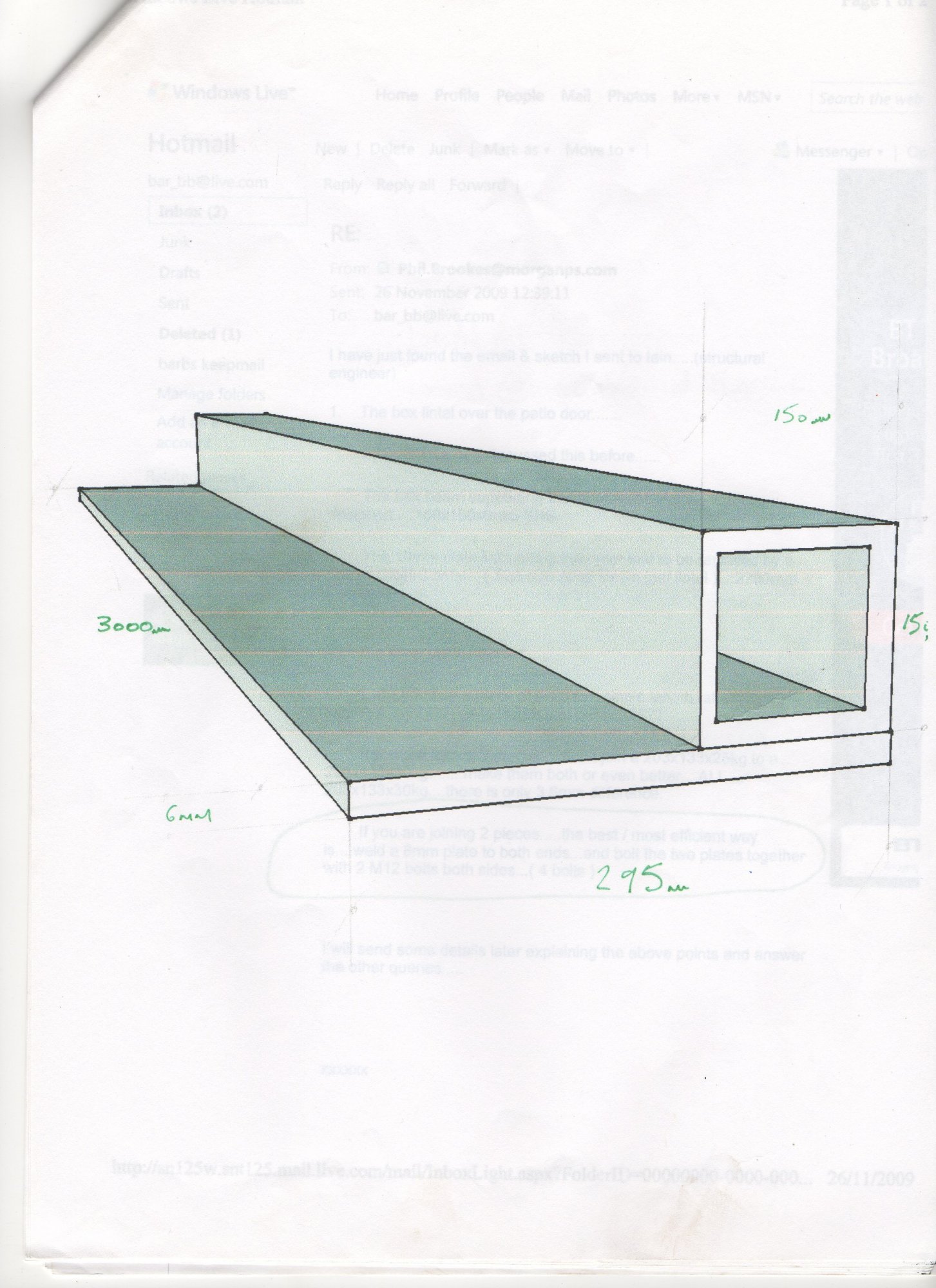

Part of my structure has a ring beam of UC supported at one end by tube (CHS). There's no detail on how it's joined. The bottom I'm guessing some sort of plate on the floor, but at the top the diameter of the CHS is pretty much the same to the beam it supports (88.9x4 mm CHS under a 152x89x16 UB). How are the two attached? Welded?

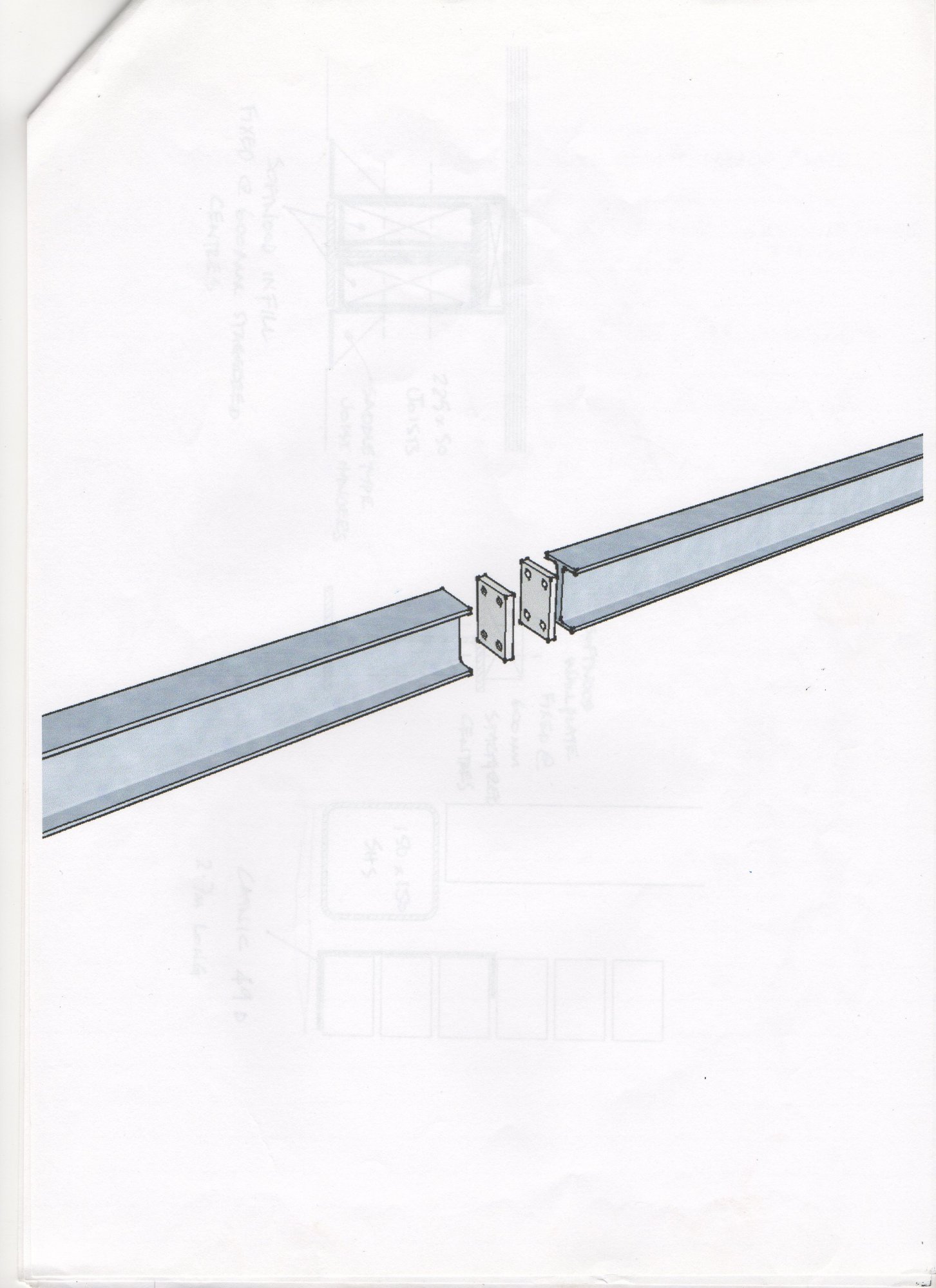

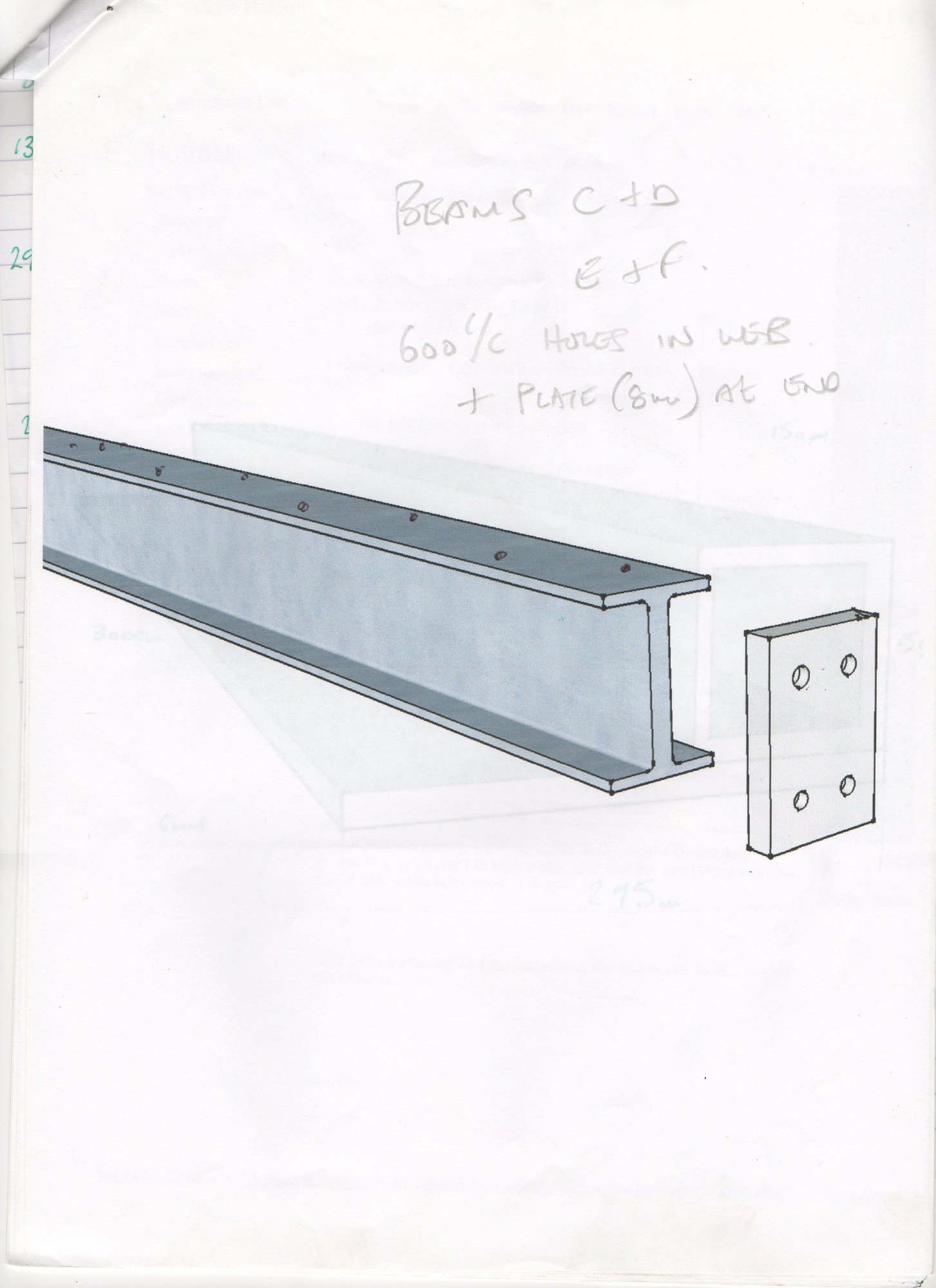

The other end of the beams are bolted to a bigger (203x203x71 UC) beam with cleats. The calculation picture (which has clearly come out of some software) shows the top of the beams flush, rather than the bottom being flush. I assume that this is just how the software prints it out and it's not important what height the cleats are bolted to on the bigger beam?

I had thought I was missing a joint bolting where two beams join at right-angles (the 203x203x71 UC and a separate 152x152x37 UC holding an upstairs wall) until I realised that of course the second is much shorter then the first. I'm assuming that the end of the 152UC can rest on top of the bottom flange of the 203UC?

Part of my structure has a ring beam of UC supported at one end by tube (CHS). There's no detail on how it's joined. The bottom I'm guessing some sort of plate on the floor, but at the top the diameter of the CHS is pretty much the same to the beam it supports (88.9x4 mm CHS under a 152x89x16 UB). How are the two attached? Welded?

The other end of the beams are bolted to a bigger (203x203x71 UC) beam with cleats. The calculation picture (which has clearly come out of some software) shows the top of the beams flush, rather than the bottom being flush. I assume that this is just how the software prints it out and it's not important what height the cleats are bolted to on the bigger beam?

I had thought I was missing a joint bolting where two beams join at right-angles (the 203x203x71 UC and a separate 152x152x37 UC holding an upstairs wall) until I realised that of course the second is much shorter then the first. I'm assuming that the end of the 152UC can rest on top of the bottom flange of the 203UC?