hi everyone,

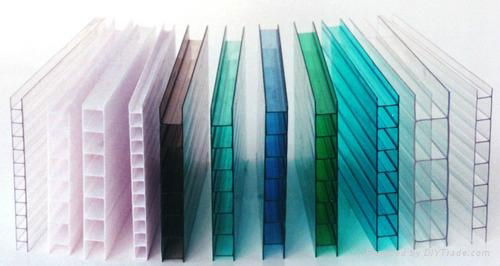

I'm thinking about lining shower walls with hollow polycarbonate sheet:

I will build shower walls with plasterboard, then line with polycarbonate sheeting. There will be 1 corner join, sealed with silicone. Will seal join to shower base.

Would like to install strip lighting below the polycarbonate, such that the walls are illuminated themselves.

Are there any draw backs to using this material? Might condensation build up in the hollow section? I could seal the top and bottom to prevent this.

(its easy to clean, low cost, easy to install, looks modern, suits lighting effects, durable).

thanks / simon

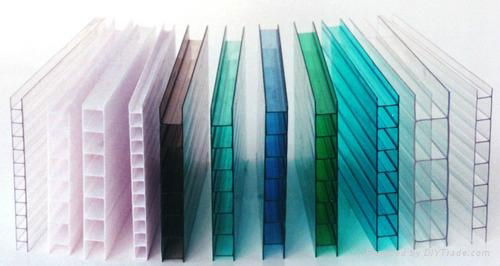

I'm thinking about lining shower walls with hollow polycarbonate sheet:

I will build shower walls with plasterboard, then line with polycarbonate sheeting. There will be 1 corner join, sealed with silicone. Will seal join to shower base.

Would like to install strip lighting below the polycarbonate, such that the walls are illuminated themselves.

Are there any draw backs to using this material? Might condensation build up in the hollow section? I could seal the top and bottom to prevent this.

(its easy to clean, low cost, easy to install, looks modern, suits lighting effects, durable).

thanks / simon