Hi,

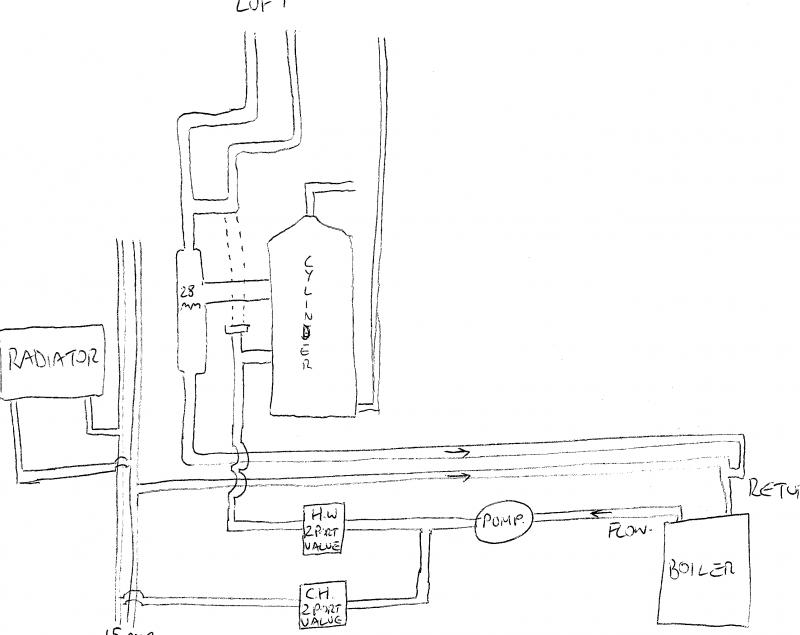

I've just moved into a house with a 'traditional' HW and CH layout.

The central heating & hot water work fine, but the pipework is not plumbed as I expected.

Firstly, from what I understand, the vent pipe to the feed & expansion tank should come off the flow pipe from the boiler before any valves, pumps, etc. However, my vent pipe appears to split off somewhere in the airing cupboard, after the pump and valves. Is this safe?

Secondly, I also thought that the flow from the boiler should feed the upper pipe of the coil in the hot water cylinder and returns back to the boiler via the lower pipe.

On my hot water cylinder, the flow enters the lower pipe and returns back to the boiler via the upper pipe. Is this incorrect or less efficient?

Assuming my understand is correct and the pipework is incorrect, any advice would be appreciated.

Cheers,

Paul.

I've just moved into a house with a 'traditional' HW and CH layout.

The central heating & hot water work fine, but the pipework is not plumbed as I expected.

Firstly, from what I understand, the vent pipe to the feed & expansion tank should come off the flow pipe from the boiler before any valves, pumps, etc. However, my vent pipe appears to split off somewhere in the airing cupboard, after the pump and valves. Is this safe?

Secondly, I also thought that the flow from the boiler should feed the upper pipe of the coil in the hot water cylinder and returns back to the boiler via the lower pipe.

On my hot water cylinder, the flow enters the lower pipe and returns back to the boiler via the upper pipe. Is this incorrect or less efficient?

Assuming my understand is correct and the pipework is incorrect, any advice would be appreciated.

Cheers,

Paul.