You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

And just how much pressure drop difference is their between say a small ( K1 type) 438mm and a 2165mm (Length) assuming heights are the same ,lets say 530mm. (Myson).

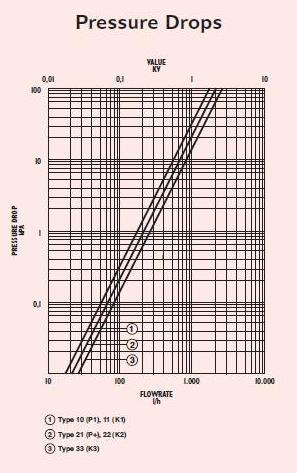

This graph is taken from the Stelrad Elite Catalogue. It's not the size of rad but the flow rate and, to a limited extent, the type of rad which determines the pressure drop across the rad.

I'm actually a fluid mechanics lecturer! i'm an aerothermal engineer

but I never really understood the " Law of Communicating Vessels"

Is a circulator in this case not just a paddle wheel pump? the fluid which you push out of the discharge goes round the circuit and comes back to the suction (inlet). The fluid returning to the suction will obviously be at lower pressure than the discharge but if there is too much resistance (head/friction etc) then the paddle wheel will not send any water around the system at all - ie a tall block of flats.

no, really don’t get that thing about the vessels. Didn’t know that central heating used impeller pumps either.

I'm going to work out the pressure loss tomorrow and actually quantify how much head loss i've got. There's also a whole host of parameters to fiddle with on the pump so i'll check them first.

maybe you should quantify setting 3 and leave there

Quoting from the book

"In closed loop systems, there is a maximum elevation an accelerator can transfer fluid to. This is dependent on a number of factors primarily fluid viscosity, density and flow velocity".

Reading a bit further down

"The height of the fluid is limited as the two legs of the system are not balanced. There is significantly more resistance in the vertical leg immediately after the discharge of the accelerator than the leg after the restriction. The accelerator must be able to generate sufficient pressure to overcome the loss caused by the fluid friction and the internal loss from the elevation change."

Utter and complete bolleaux.

If that is in your book, it is referring to a pump moving a liquid to a higher level. In this case, the accelerator/pump is not transferring a fluid to a higher level, there is an equal volume flowing from high to low level and the two legs of the system are balanced.

You would have known that.

I've no idea what the restriction referred to is.

You had thought the pump head referred to the height of the building and now you are just making smoke to hide your embarrassment. It would have been an understandable and forgivable mistake, for a Year 1 NVQ trainee. I do not believe that you have any engineering qualifications. Do one. I'm sure that, in future, everyone will treat your discourses with the respect that you feel they deserve.

If that is in your book, it is referring to a pump moving a liquid to a higher level. In this case, the accelerator/pump is not transferring a fluid to a higher level, there is an equal volume flowing from high to low level and the two legs of the system are balanced.Quoting from the book

"In closed loop systems, there is a maximum elevation an accelerator can transfer fluid to. This is dependent on a number of factors primarily fluid viscosity, density and flow velocity".

Reading a bit further down

"The height of the fluid is limited as the two legs of the system are not balanced. There is significantly more resistance in the vertical leg immediately after the discharge of the accelerator than the leg after the restriction. The accelerator must be able to generate sufficient pressure to overcome the loss caused by the fluid friction and the internal loss from the elevation change."

You would have known that.

I've no idea what the restriction referred to is.

You had thought the pump head referred to the height of the building and now you are just making smoke to hide your embarrassment.

Having castigated Sanji for his bad workmanship, I think I should now come to his defence.

Danfoss have produced The Heating Book which goes into considerable detail about the design of District Heating Systems for towns and blocks of flats. Chapter Four has a section on the effects of gravity in high rise buildings which makes interesting reading as it tends to agree with Sanji's views.

In this chapter, the gravity effects of the risers of an 18 storey (54m) building are calculated as follows:

Flow Temp: 95oC - Density: 962.2 kg/m3

Return Temp: 70oC - Density: 977.8

Δρ = 15.6 kg/m3

Δp = 54 × 15.6 x 9.81

= 8.264 Pa = 8.3 kPa

This accounted for 30% of the pressure differential in the index circuit!

Although most of the book is not relevant, talking about power stations etc, some of it is very interesting and useful. I learnt all about valve authority and that the heat loss from a vertical uninsulated pipe is 20% less than from a horizontal one.

Having castigated Sanji for his bad workmanship, I think I should now come to his defence.

Danfoss have produced The Heating Book which goes into considerable detail about the design of District Heating Systems for towns and blocks of flats. Chapter Four has a section on the effects of gravity in high rise buildings which makes interesting reading as it tends to agree with Sanji's views.

In this chapter, the gravity effects of the risers of an 18 storey (54m) building are calculated as follows:

Flow Temp: 95oC - Density: 962.2 kg/m3

Return Temp: 70oC - Density: 977.8

Δρ = 15.6 kg/m3

Δp = 54 × 15.6 x 9.81

= 8.264 Pa = 8.3 kPa

This accounted for 30% of the pressure differential in the index circuit!

Although most of the book is not relevant, talking about power stations etc, some of it is very interesting and useful. I learnt all about valve authority and that the heat loss from a vertical uninsulated pipe is 20% less than from a horizontal one.

Errrrr, yeah, but the 95 degC flow is less dense than the 70 degC return, so that 8.3 kPa pressure difference is assisting the pump ( unless the boiler is on the upper floors). This is the opposite of what S-V has claimed.

See my post of Fri Dec 28, 2007 7:11 pm;

"The truth is the opposite; you will get (apparent) reduced head losses if you're pumping the flow upwards because of the gravity circulation effect; the hotter flow column is less dense than the descending return column."

In this case, the differential pressure due to 'gravity circulation' = (977.8- 962.2) x 9.81 x 54 Pa = 8.3 kPa.

That 8.3 kPa differential pressure is pushing the flow upwards.

Now S-V just needs to find a similar effect pushing the flow downwards with a pressure of approximately (8.3 + 19.4) kPa, enough to stop all circulation. In fact, it would have to be greater than that, since the pump head would increase as the flow rate decreased.

Any suggestions?

If you had an 2" pipe rising from the plant room straight up through the building to the loft/roof area, with legs off for each floor and dropping into one 21/2" or 2 x 2" return pipes it would work by gravity.

The biggest problem would be stopping the circulation and the pressure in the plant room.

The biggest problem would be stopping the circulation and the pressure in the plant room.

I learnt all about valve authority and that the heat loss from a vertical uninsulated pipe is 20% less than from a horizontal one.

Thats why I hold my soldering iron vertical when I want it to warm up quickly and horizontally when I want it to rest and keep itself cooler.

A vertical pipe keeps the upper parts warm with the convected heat from lower down.

Tony

To be picky, Onetap, in what circumstances might the flow be pumped downwards?Onetap said:you will get (apparent) reduced head losses if you're pumping the flow upwards because of the gravity circulation effect;

I take it all back; you are capable of rocket science.Agile said:Thats why I hold my soldering iron vertical when I want it to warm up quickly and horizontally when I want it to rest and keep itself cooler.

To be picky, Onetap, in what circumstances might the flow be pumped downwards?Onetap said:you will get (apparent) reduced head losses if you're pumping the flow upwards because of the gravity circulation effect;

When the boiler is on the top floor!

I have forgotten where it was, perhaps a Birmingham tower block?

Tony

To be picky, Onetap, in what circumstances might the flow be pumped downwards?Onetap said:you will get (apparent) reduced head losses if you're pumping the flow upwards because of the gravity circulation effect;

When the boiler is on the top floor!

I have forgotten where it was, perhaps a Birmingham tower block?

Tony

Drayton Gadens, or didn't you see that one

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 46

- Views

- 21K

- Replies

- 7

- Views

- 3K