Hi there,

We are installing a Stanley Lismore wood burning boiler stove.

We are trying to figure out the installation process. We are planning on laying all the plumbing work ourselves and getting a plumbing (my uncle) in to solder joints etc.

We are looking to drill an access hole 9inchs above the existing tongue plate in the fireplace to get the stoves flue into the chimney. Are there are special ways to place the pipe through. Would we need to sleeve the pipe and use fire rope etc..

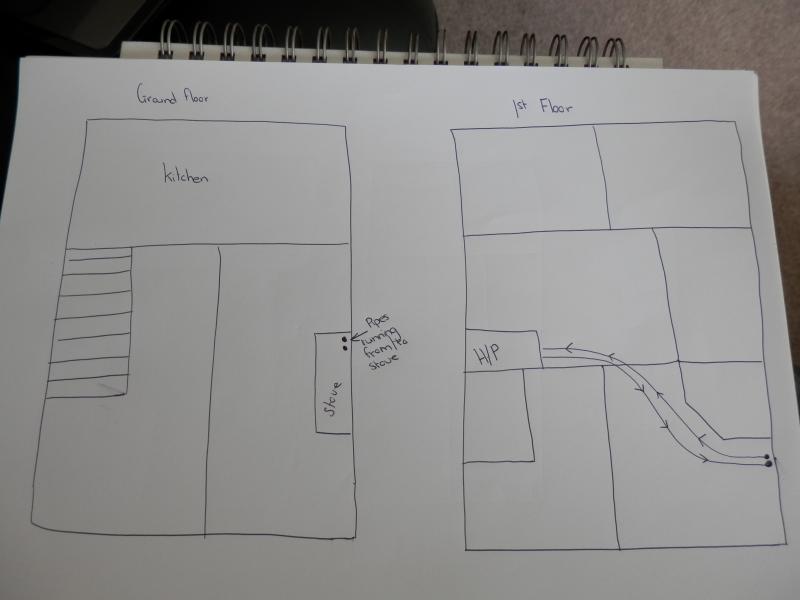

Also there are 2 pipes out of the back of the stove we are running them up the wall (stanadard height ceilings) and along the floor boards on the 1st floor level if not at a slight gradient.

These pipes I am connecting to the cylinder and teeing off to the radiators pipes aswell.

We have a single coil cylinder and we are not changing it.

We are also building a chimney breast arond the stove. Would people recommend this to be done in block or fire proof plasterboard and alloy studs.

http://media.diynot.com/192000_191550_48910_56541670_thumb.jpg

If anybody could give me a better idea would be appreciated as there are 100 ways of doing it. It is just getting the right balance to allow the heat to radiate downstairs radiators.

We are installing a Stanley Lismore wood burning boiler stove.

We are trying to figure out the installation process. We are planning on laying all the plumbing work ourselves and getting a plumbing (my uncle) in to solder joints etc.

We are looking to drill an access hole 9inchs above the existing tongue plate in the fireplace to get the stoves flue into the chimney. Are there are special ways to place the pipe through. Would we need to sleeve the pipe and use fire rope etc..

Also there are 2 pipes out of the back of the stove we are running them up the wall (stanadard height ceilings) and along the floor boards on the 1st floor level if not at a slight gradient.

These pipes I am connecting to the cylinder and teeing off to the radiators pipes aswell.

We have a single coil cylinder and we are not changing it.

We are also building a chimney breast arond the stove. Would people recommend this to be done in block or fire proof plasterboard and alloy studs.

http://media.diynot.com/192000_191550_48910_56541670_thumb.jpg

If anybody could give me a better idea would be appreciated as there are 100 ways of doing it. It is just getting the right balance to allow the heat to radiate downstairs radiators.

House Diagram

This a diagram of our house. It shows the stove and then the upstairs to show the way we are...