Hi there folks

Firstly this is going to be a big post I know it so will start by saying thank you to anyone who reads it entirely and a further thank you to anyone that can help, suggest options or suggest alternatives.

I found this site while looking for advice on insulating our extension/outbuilding and after many hours of searching about I was hoping for some reassurance from experienced people on the approach I wish to take with it.

I will include lots of photos to aid with getting an idea for space and layout.

Basically it appears as if there was a porch for the back door and then a brick out building (perhaps for storage/tools etc) added onto that.

The house back door is double glazed, this once opened leads straight into the open area.

The first metre or so is where I imagine the proper porch was. From the outside (in garden) you can see the concrete bass with some damp course etc but this stops at the end of the door frame. You can then see the base of concrete for the out building.

Are the far wall I was think i'd see a join in brick work etc but it appears as if it was just like a simple partition put up separating the building etc. I can't imagine why it would have been done this way as the porch would be insulated in the ceiling and the dpm under the concrete but the outer section just concrete,slate and then brick. STRANGE!

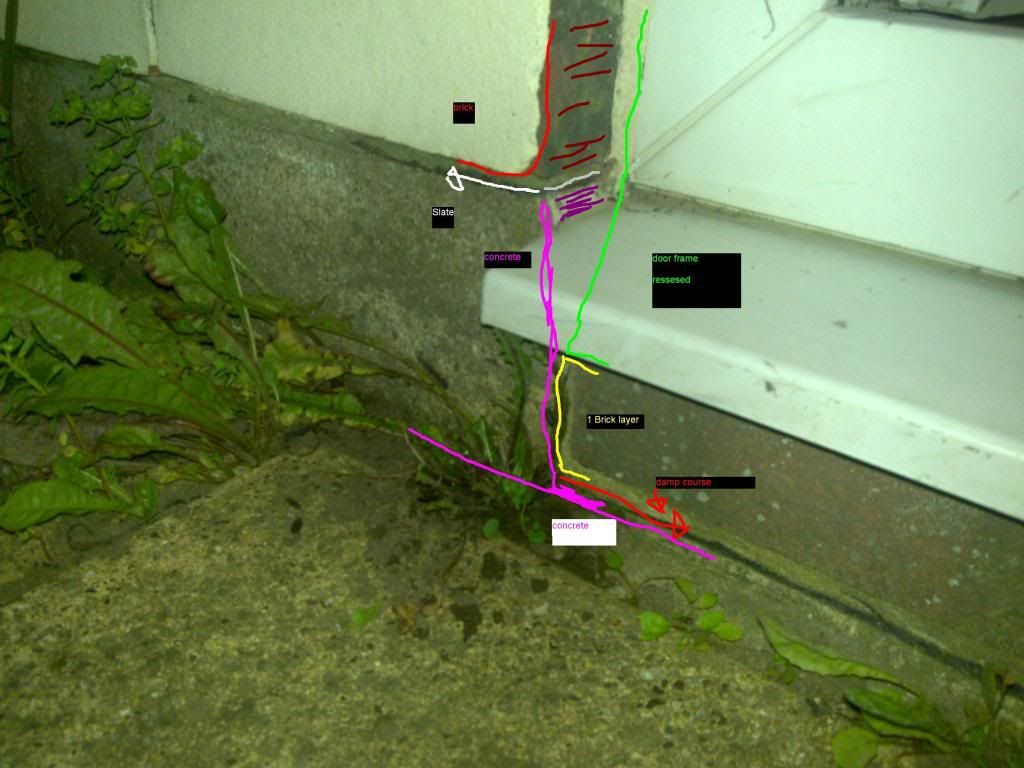

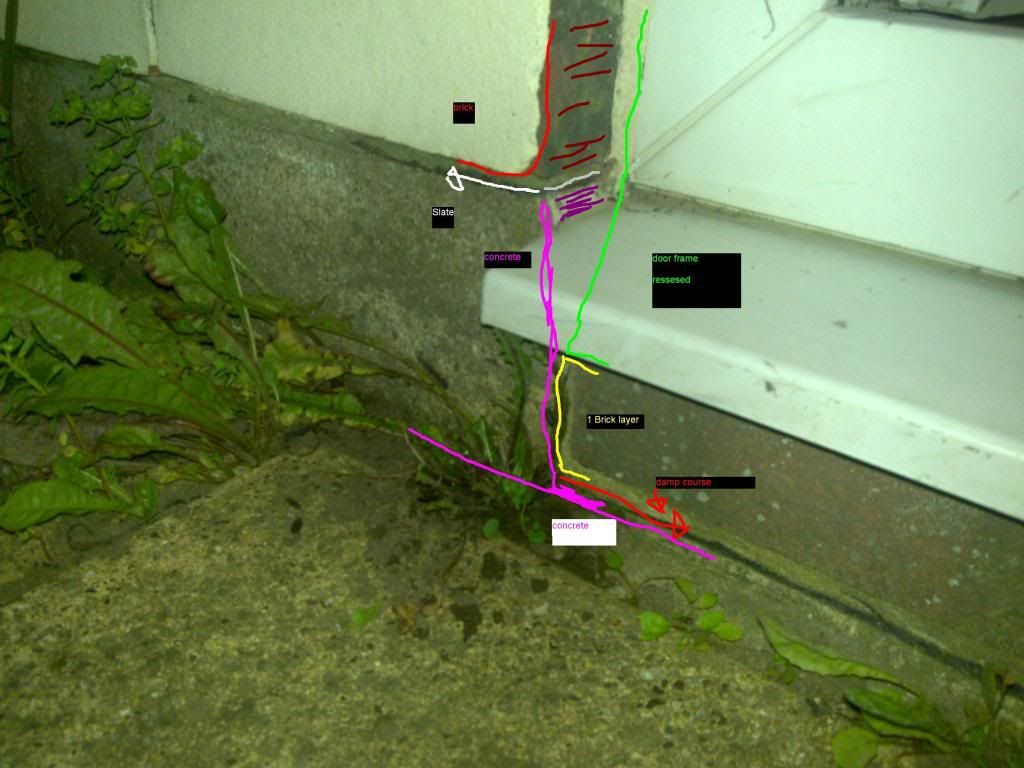

Here's a pic with some professional descriptions on it lol!

As you can see the dpm stops where the brick work on the this side starts.

The outer building is a concrete base a layer of slate and then brick. Not sure on the terminology but i'd call it single skin brick wall just a normal wall made of brick... just trying to measure it seems about 10cm from outside to in. lol

Down to the nitty gritty.

here is a photo of the actual space i'll working on (4270mm x 1850mm)

I have never seen damp patches, puddles on the floor etc. walls always feel nice in temp even during the freezing cold it's literally just the floor that is cold.

I need to keep as much space as possible as its only 4 metres or so by 2m, therefore I don't want to start building an internal structure such as studs etc and being 6ft 4" head room is an issue when discussions of a floating floor start.

It will be for a studio of sorts but soundproofing is not really an issue. Also

With this in mind my plan was (before i came here lol):

Floor =

Water seal/concrete sealant

DPM

50mm x 25mm) joists

25mm polystyrene board

18mm chipboard flooring

Ceiling =

Rockwool or similar insulation between joists

Maybe a vapour sheet/membrane?

Plasterboard - not sure of thickness thin as I can get away with

Walls - this is my main unknown area!! (looking at several topics but this in particular - http://www.diynot.com/forums/viewtopic.php?t=166351

I was thinking at first the following:

Masonary sealant

dot and dab insulated plaster board (i believe this is polystyrene backed??)

Then been reading about vapour needing to be released etc

then i read this - http://www.diynot.com/forums/viewtopic.php?t=76247

So now thinkings something along the lines of

dpm

25mm treated battons ( i will stain/treat them too) with 25mm polystyrene insulation between

vapour sheet

thin plasterboard.

If this is ok? a further few questions lol

1) how do i attach the dpm to the wall? would have through nailing etc would cause breaks and there break the point of using it.

2) I'm guessing i let the floor dpm over lap the wall dpm thus keeping all water out of the room - so in theory do the wall dpm first then the floor but then build the floor and then the walls.

Finally thank yous o much to all that read and maybe help out!!!!!!

[/b]

[/b]

Firstly this is going to be a big post I know it so will start by saying thank you to anyone who reads it entirely and a further thank you to anyone that can help, suggest options or suggest alternatives.

I found this site while looking for advice on insulating our extension/outbuilding and after many hours of searching about I was hoping for some reassurance from experienced people on the approach I wish to take with it.

I will include lots of photos to aid with getting an idea for space and layout.

Basically it appears as if there was a porch for the back door and then a brick out building (perhaps for storage/tools etc) added onto that.

The house back door is double glazed, this once opened leads straight into the open area.

The first metre or so is where I imagine the proper porch was. From the outside (in garden) you can see the concrete bass with some damp course etc but this stops at the end of the door frame. You can then see the base of concrete for the out building.

Are the far wall I was think i'd see a join in brick work etc but it appears as if it was just like a simple partition put up separating the building etc. I can't imagine why it would have been done this way as the porch would be insulated in the ceiling and the dpm under the concrete but the outer section just concrete,slate and then brick. STRANGE!

Here's a pic with some professional descriptions on it lol!

As you can see the dpm stops where the brick work on the this side starts.

The outer building is a concrete base a layer of slate and then brick. Not sure on the terminology but i'd call it single skin brick wall just a normal wall made of brick... just trying to measure it seems about 10cm from outside to in. lol

Down to the nitty gritty.

here is a photo of the actual space i'll working on (4270mm x 1850mm)

I have never seen damp patches, puddles on the floor etc. walls always feel nice in temp even during the freezing cold it's literally just the floor that is cold.

I need to keep as much space as possible as its only 4 metres or so by 2m, therefore I don't want to start building an internal structure such as studs etc and being 6ft 4" head room is an issue when discussions of a floating floor start.

It will be for a studio of sorts but soundproofing is not really an issue. Also

With this in mind my plan was (before i came here lol):

Floor =

Water seal/concrete sealant

DPM

50mm x 25mm) joists

25mm polystyrene board

18mm chipboard flooring

Ceiling =

Rockwool or similar insulation between joists

Maybe a vapour sheet/membrane?

Plasterboard - not sure of thickness thin as I can get away with

Walls - this is my main unknown area!! (looking at several topics but this in particular - http://www.diynot.com/forums/viewtopic.php?t=166351

I was thinking at first the following:

Masonary sealant

dot and dab insulated plaster board (i believe this is polystyrene backed??)

Then been reading about vapour needing to be released etc

then i read this - http://www.diynot.com/forums/viewtopic.php?t=76247

So now thinkings something along the lines of

dpm

25mm treated battons ( i will stain/treat them too) with 25mm polystyrene insulation between

vapour sheet

thin plasterboard.

If this is ok? a further few questions lol

1) how do i attach the dpm to the wall? would have through nailing etc would cause breaks and there break the point of using it.

2) I'm guessing i let the floor dpm over lap the wall dpm thus keeping all water out of the room - so in theory do the wall dpm first then the floor but then build the floor and then the walls.

Finally thank yous o much to all that read and maybe help out!!!!!!