Hi,

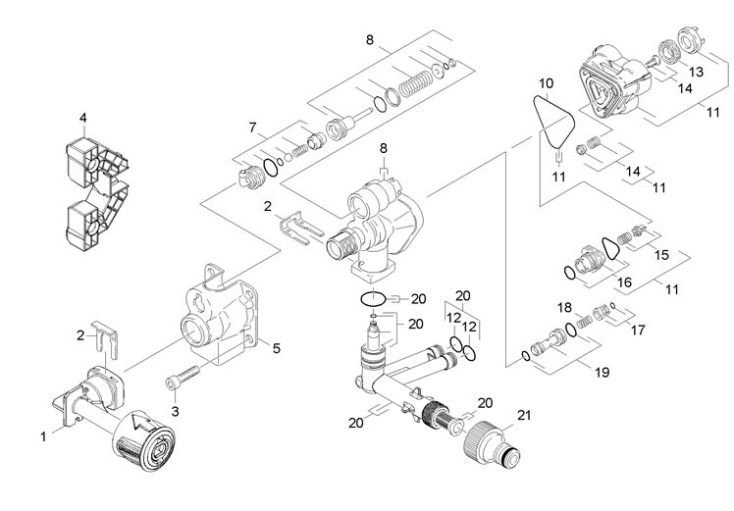

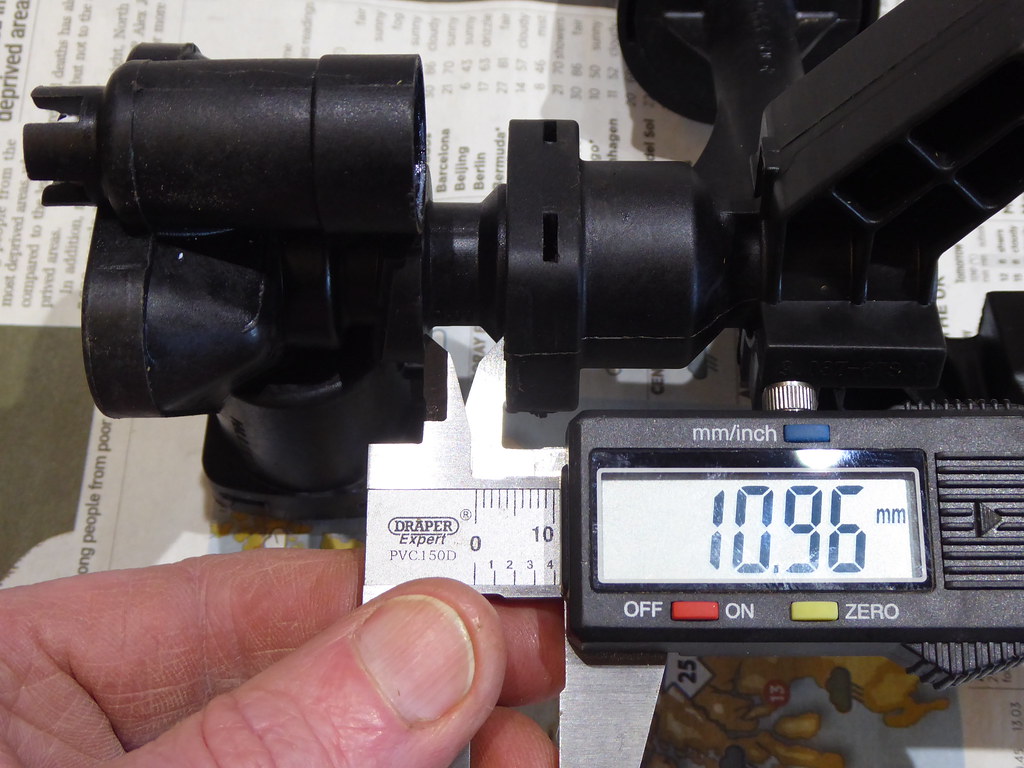

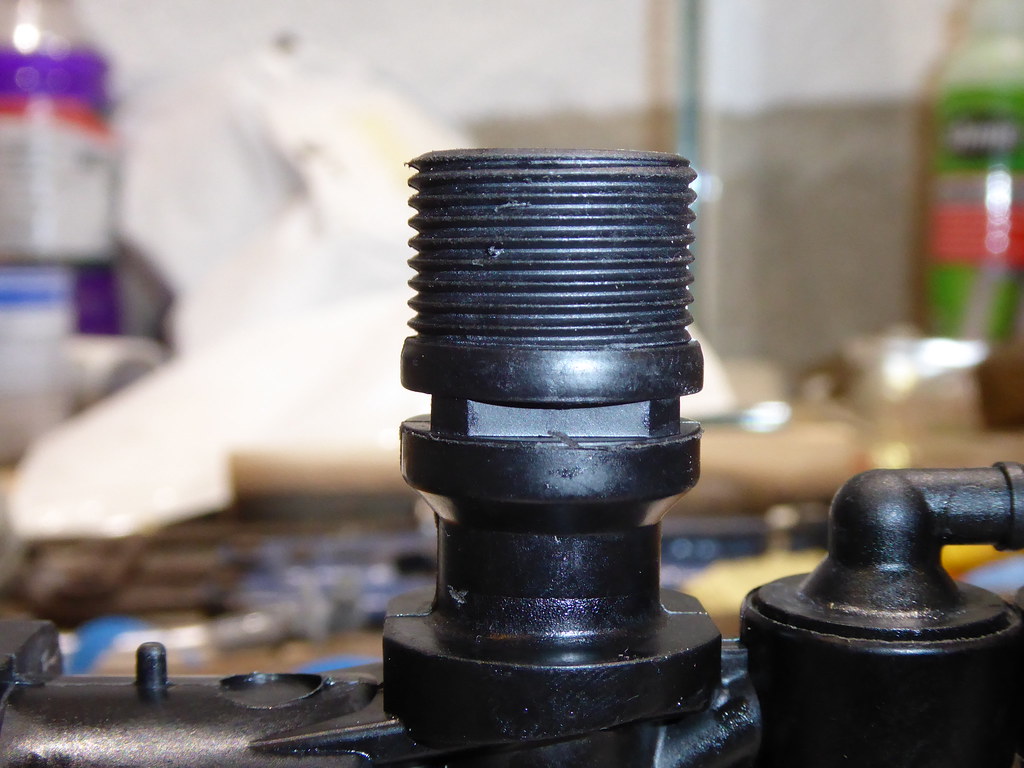

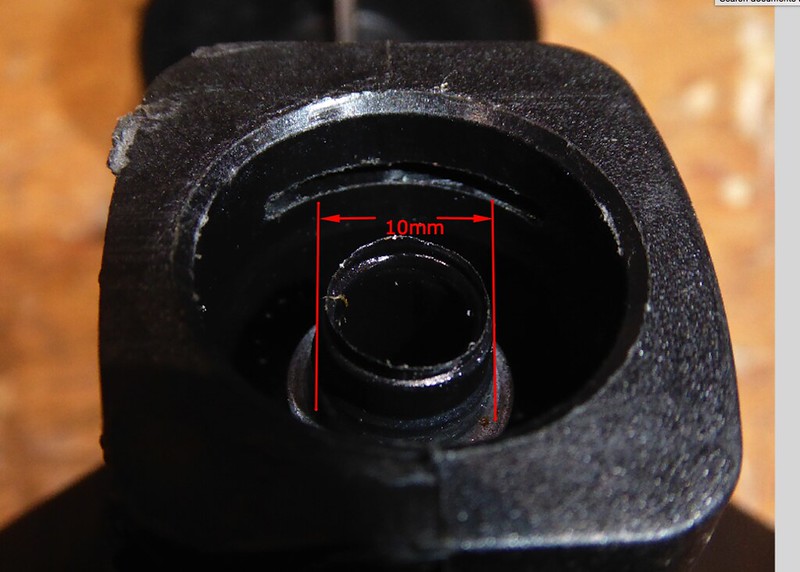

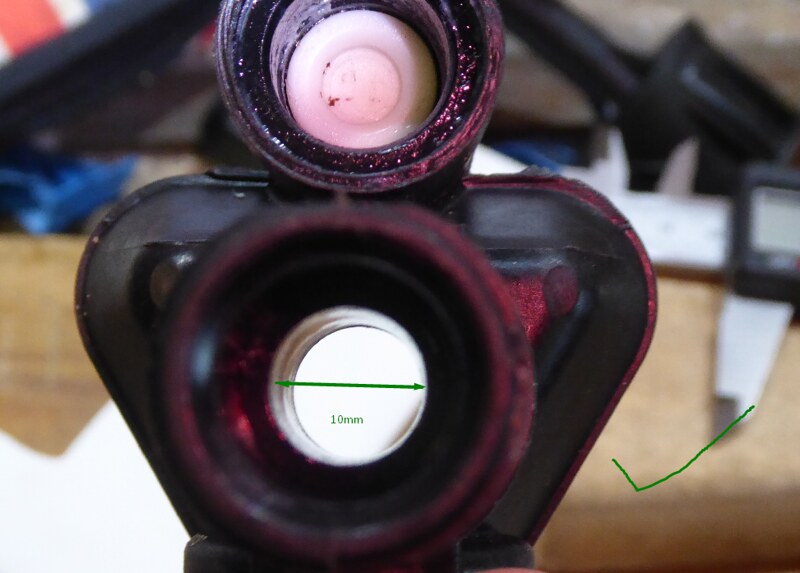

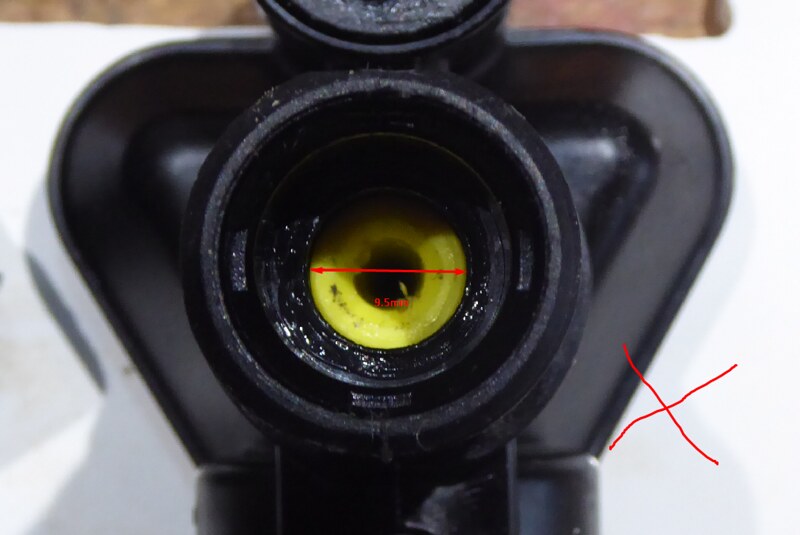

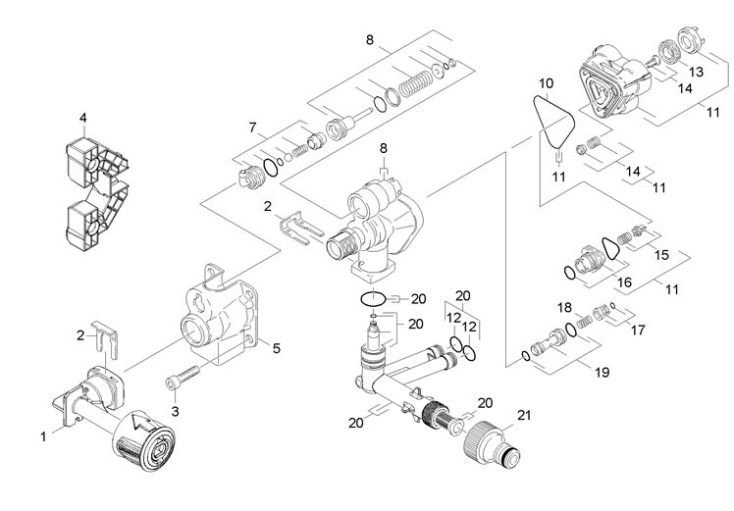

Our K4 pressure washer has developed a fault since last use. The motor runs continuously when switched on, and it leaks from somewhere in and around the pump. The only apparent fault is a a crack in the pump housing where the detergent feed connects just above the figure "8" in the drawing. When the water supply is connected there is a very slow leak from that point, maybe a drop or so per second. However it doesn't appear to be the main issue. When the pump runs water seems to spray out all the way round. I'm finding it hard or impossible to see where it's actually coming from because the spray covers everything.

Any suggestions on narrowing it down, or of known problem locations that might not look obvious? I can't see any other damage apart from that hairline crack. I was thinking maybe wrap masking tape around various places and see where the tape gets blown off.

Moving on, assuming I can get it fixed I have a suspicious that this might have been caused by the thing freezing, however there doesn't seem to be any way of draining it. Instructions just say to drain by releasing the pressure, but that must still leave the insides full of water. Again, any ideas on how to drain down properly?

Thanks in advance, Tony S

Our K4 pressure washer has developed a fault since last use. The motor runs continuously when switched on, and it leaks from somewhere in and around the pump. The only apparent fault is a a crack in the pump housing where the detergent feed connects just above the figure "8" in the drawing. When the water supply is connected there is a very slow leak from that point, maybe a drop or so per second. However it doesn't appear to be the main issue. When the pump runs water seems to spray out all the way round. I'm finding it hard or impossible to see where it's actually coming from because the spray covers everything.

Any suggestions on narrowing it down, or of known problem locations that might not look obvious? I can't see any other damage apart from that hairline crack. I was thinking maybe wrap masking tape around various places and see where the tape gets blown off.

Moving on, assuming I can get it fixed I have a suspicious that this might have been caused by the thing freezing, however there doesn't seem to be any way of draining it. Instructions just say to drain by releasing the pressure, but that must still leave the insides full of water. Again, any ideas on how to drain down properly?

Thanks in advance, Tony S