R

richard7761

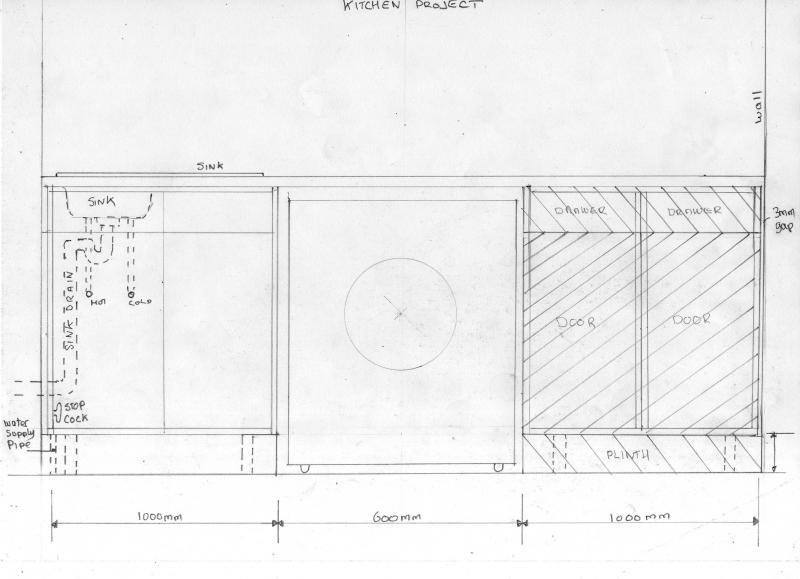

I'm using a set of base cabinets for my kitchen. The washer will be in the middle, and either side will be a space of 1000mm.

To the right of the washer will be a 1000 wide base unit.

Now, I'm not sure what to do with the 1000mm space on the left of the washer, because that is where the water supply enters and waste leaves and where the sink will be.

I have two options for the left: Fit a 500mm base unit just left of the washer leaving me to figure out the 500m space left of this base unit, or fit a 1000mm base unit.

Would the usual thing to do be to fit a 1000mmm base unit on the left and to cut out any necessary holes in the base unit? As per the drawing I've made. Thanks.

To the right of the washer will be a 1000 wide base unit.

Now, I'm not sure what to do with the 1000mm space on the left of the washer, because that is where the water supply enters and waste leaves and where the sink will be.

I have two options for the left: Fit a 500mm base unit just left of the washer leaving me to figure out the 500m space left of this base unit, or fit a 1000mm base unit.

Would the usual thing to do be to fit a 1000mmm base unit on the left and to cut out any necessary holes in the base unit? As per the drawing I've made. Thanks.

Untitled

- richard7761

- 1